Riser bush production equipment

A technology for production equipment and riser sleeves, which is applied to casting molding equipment, metal processing equipment, casting molds, etc. It can solve the problems of long molding time and low work efficiency, eliminate internal heating, improve production efficiency, and reduce labor costs. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

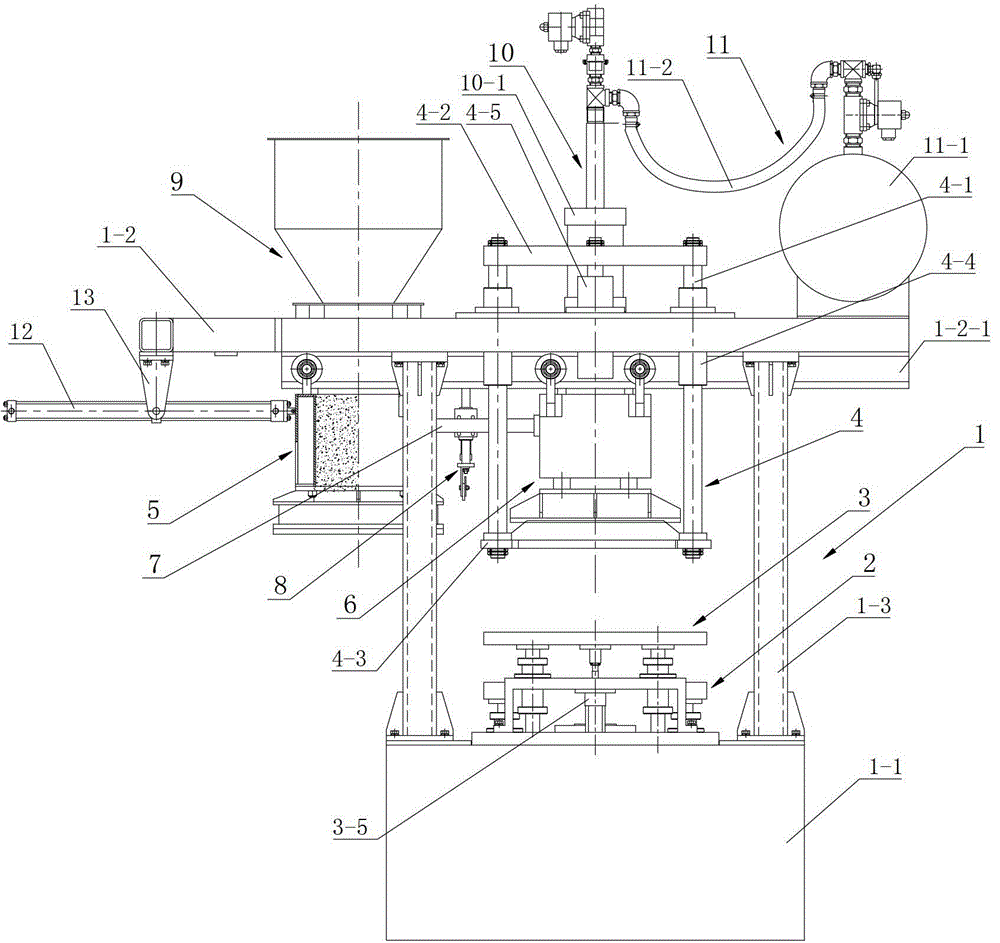

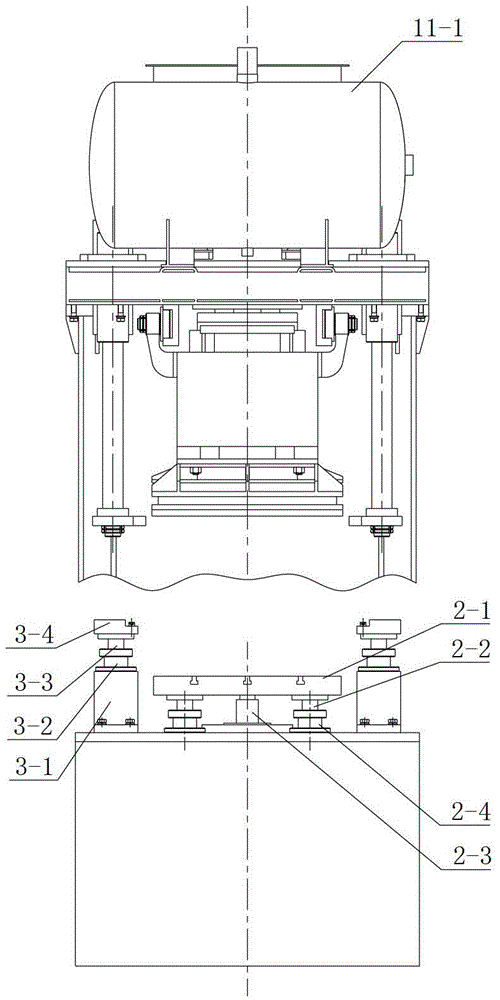

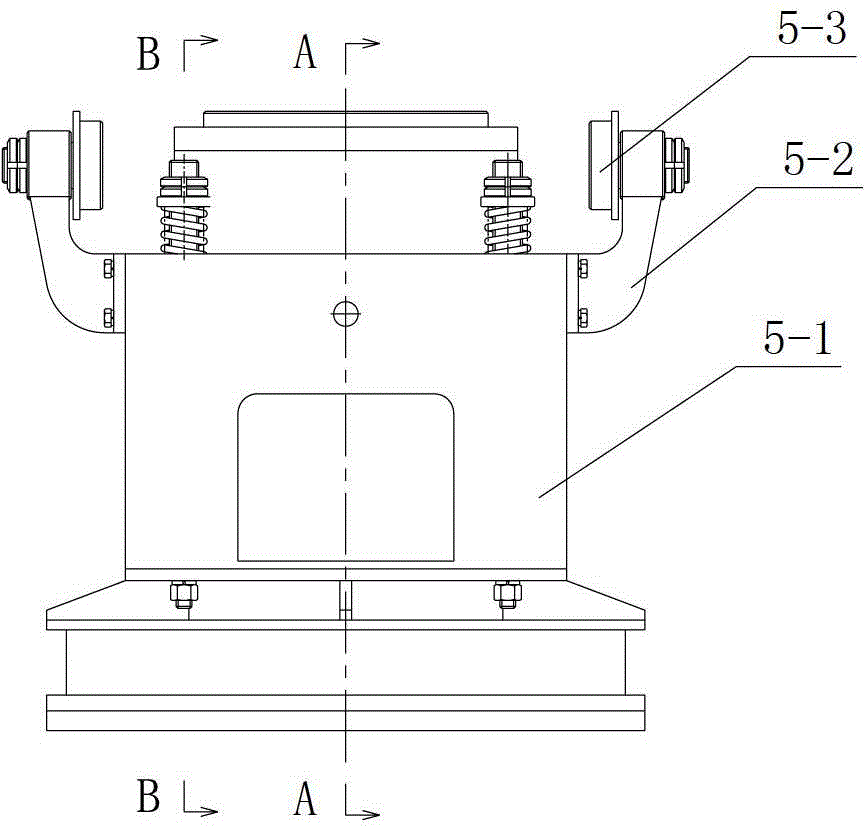

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0030] see Figure 1-10 , a riser sleeve production equipment, including a frame 1, the frame is composed of a lower base 1-1, an upper beam bracket 1-2 and several supporting columns 1-3 connecting the two. The lower base is provided with a lower mold support mechanism 2 and a shutter plate support mechanism 3 . The lower mold supporting mechanism is used to fix the lower mold and can drive the lower mold to move up and down in the vertical direction. The stencil supporting mechanism is used to support the stencil and can drive the stencil to move up and down in the vertical direction. The upper beam support is provided with an upper mold support mechanism 4 aligned with the lower mold support mechanism. The upper mold support mechanism is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com