Dry distillation cigarette

A cigarette, dry distillation technology, applied in the direction of tobacco, cigar manufacturing, application, etc., can solve the problems of difficult ignition, harm to health, inhalation, etc., and achieve the effects of low production cost, easy rolling and processing, and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

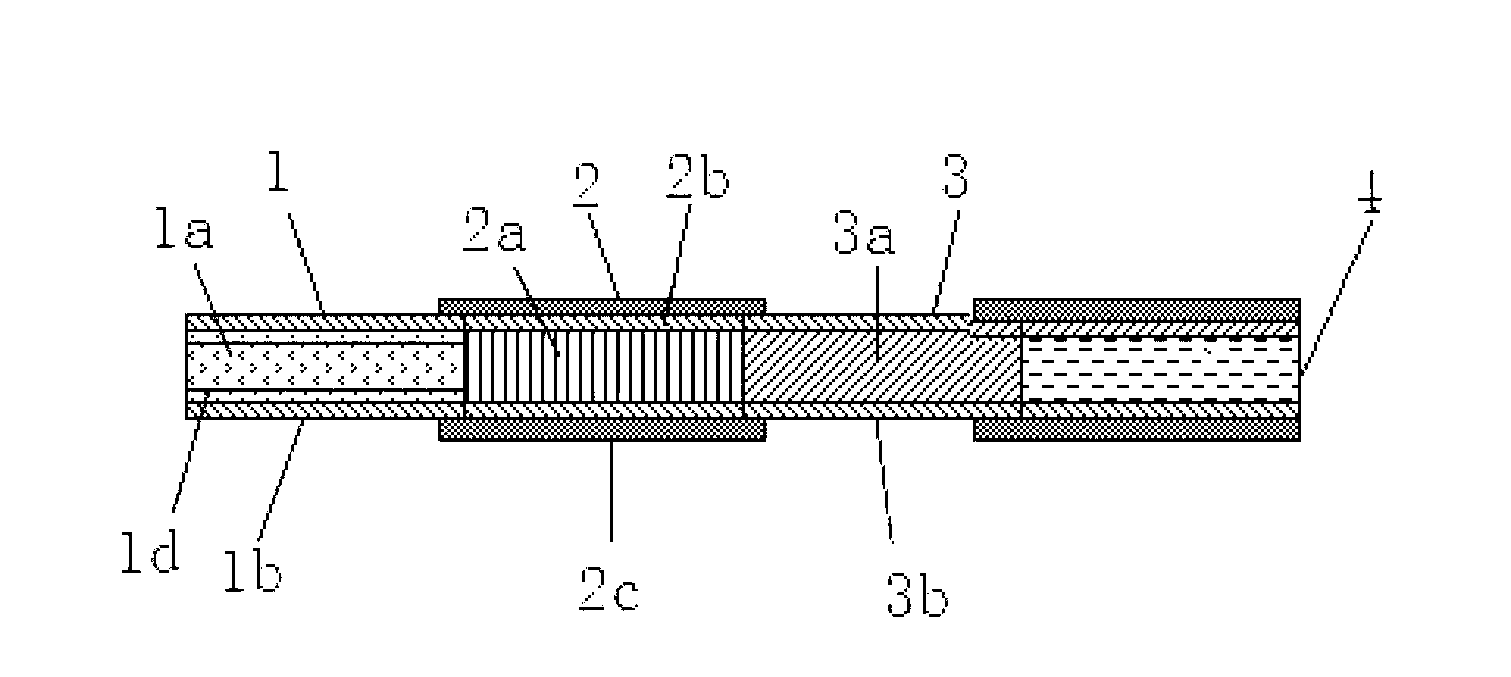

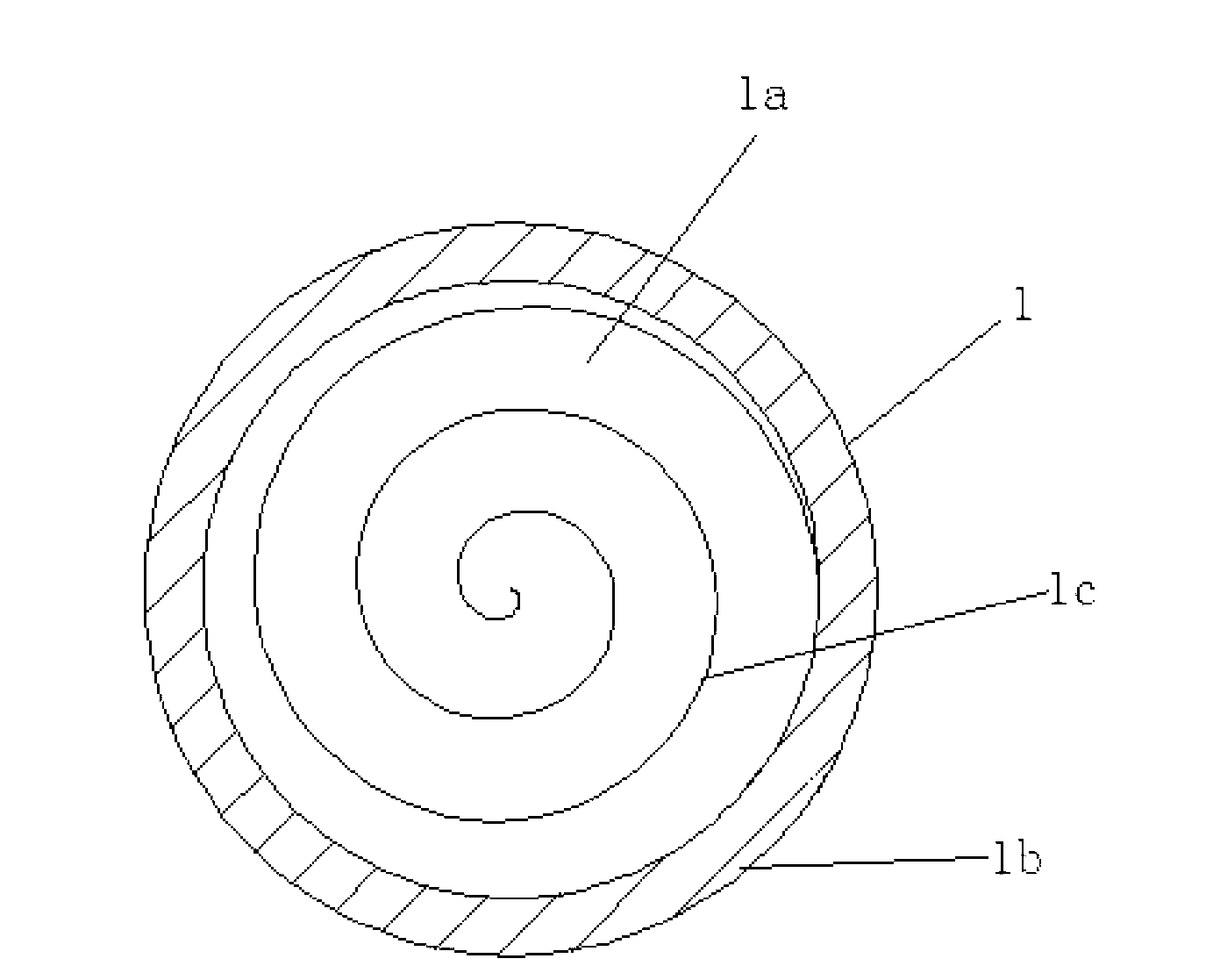

[0025] like figure 1 and figure 2 As shown, a dry distillation type cigarette is composed of a heat source section 1, a dry distillation section 2, a filling section 3 and a stick section 4, and the heat source section 1, the dry distillation section 2, the filling section 3 and the stick section 4 are connected in sequence. The heat source section 1 includes a carbonaceous heat source 1a and a cigarette paper 1b wrapped in the outer layer of the carbonaceous heat source 1a, and the retort section 2 is composed of retort shredded tobacco 2a, a heat-conducting and insulating layer 2b, and a flame-retardant wrapping layer 2c from the inside to the outside. The filling section 3 is composed of a tobacco product 3a and a cigarette paper 3b for wrapping the tobacco product 3a.

[0026] The inside of the carbonaceous heat source 1a is provided with a pore 1c penetrating in the axial direction. The carbonaceous heat source 1a is a multi-layer structure rolled from a sheet-like carb...

Embodiment 2

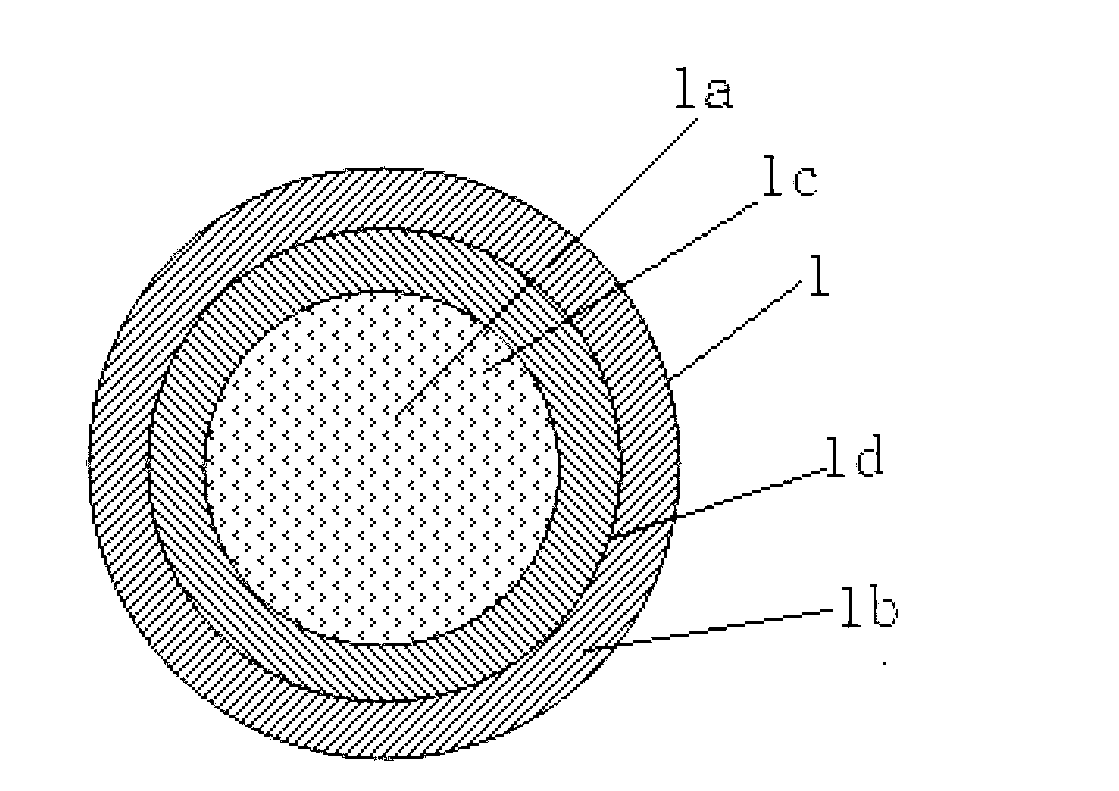

[0028] like figure 1 and image 3 As shown, a dry distillation type cigarette is composed of a heat source section 1, a dry distillation section 2, a filling section 3 and a stick section 4, and the heat source section 1, the dry distillation section 2, the filling section 3 and the stick section 4 are connected in sequence. The heat source section 1 includes a carbonaceous heat source 1a and a cigarette paper 1b wrapped in the outer layer of the carbonaceous heat source 1a, and the retort section 2 is composed of retort shredded tobacco 2a, a heat-conducting and insulating layer 2b, and a flame-retardant wrapping layer 2c from the inside to the outside. The filling section 3 is composed of a tobacco product 3a and a cigarette paper 3b for wrapping the tobacco product 3a.

[0029] The interior of the carbonaceous heat source 1a is provided with pores 1c penetrating in the axial direction. The carbonaceous heat source 1a is a porous structure made of filamentous carbonaceous m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Draw resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com