Improved food drying box

A drying box, food technology, applied in the direction of drying, drying machine, food science, etc., can solve the problems of energy waste, no reuse, etc., to achieve the effect of saving energy and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

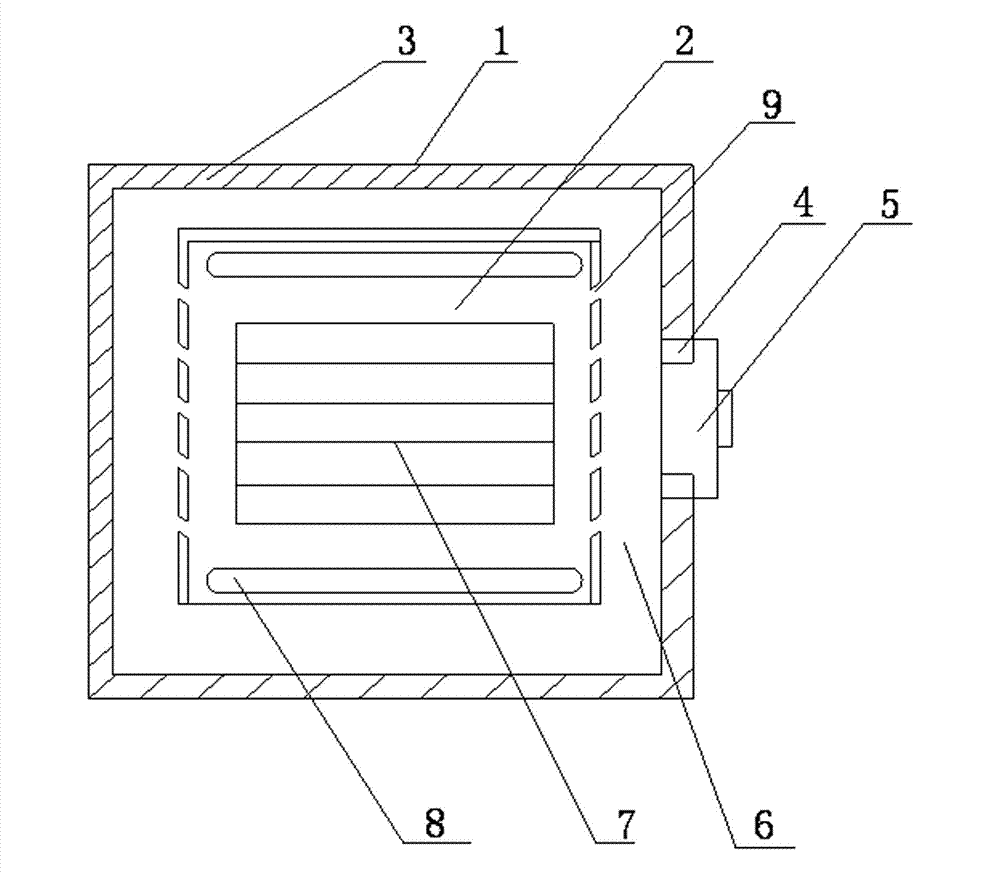

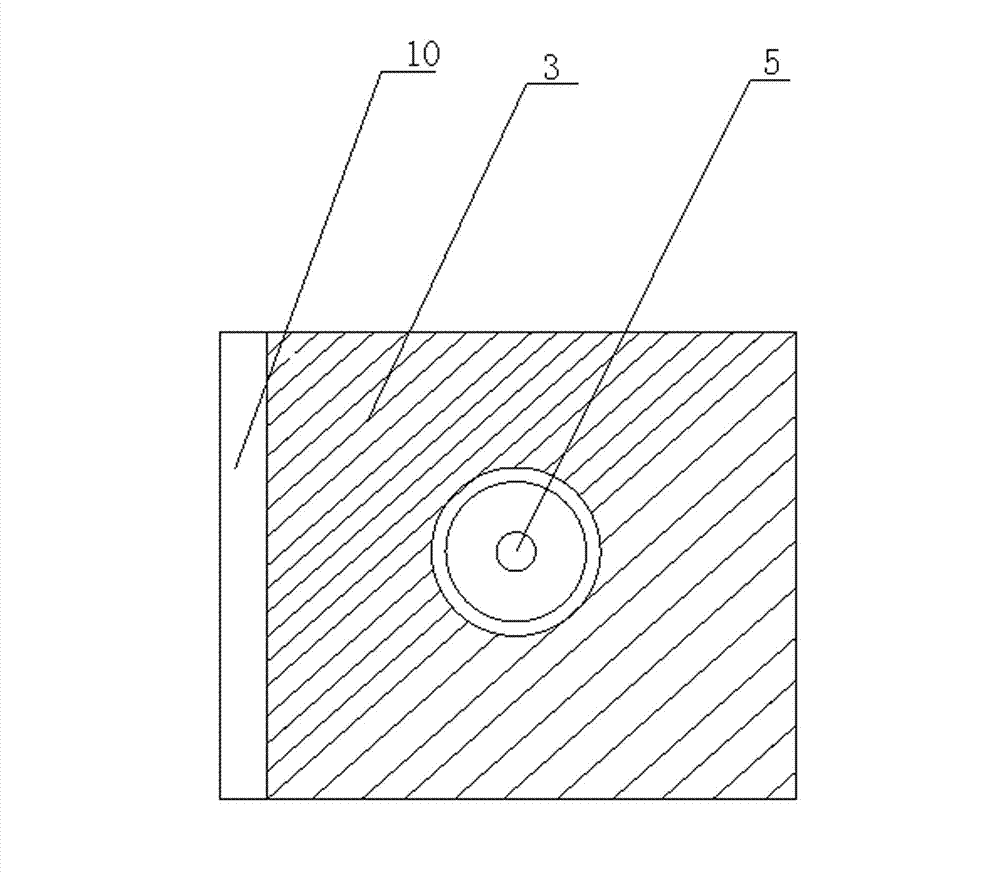

[0015] Such as figure 1 and figure 2 As shown, an improved food drying box of the present invention comprises a drying box outer cavity 1 and a drying box inner cavity 2, an insulating layer 3 is arranged outside the drying box outer cavity 1, and the drying box outer cavity 1 A cooling hole 4 is provided on one side, and the cooling hole 4 is sealed by a piston 5. A hot air duct 6 is provided between the inner cavity 2 of the drying box and the outer cavity 1 of the drying box, and a shelf 7 is arranged in the middle of the inner cavity 1 of the drying box. The upper and lower sides of the storage rack 7 are provided with heating pipes 8, the left and right sides of the storage rack 7 are provided with vent holes 9, and the front side of the outer chamber 1 of the drying box is provided with a sealed door 10 made of tempered glass. The heat generated by the heating pipe 8 can be circulated to the hot air duct 6 through the ventilation hole 9, and the food in the inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com