Stereoscopic rolling iron core intelligent transformer

A three-dimensional wound iron core, intelligent transformer technology, applied in the field of transformers, can solve the problems of reducing the service life of equipment, increasing maintenance and repair costs, and high grid voltage, and achieving the effect of reducing power consumption and saving electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to fully understand the purpose, features and technical effects of the present invention, here through the following specific embodiments, in conjunction with the accompanying drawings, the present invention is described in detail, as follows:

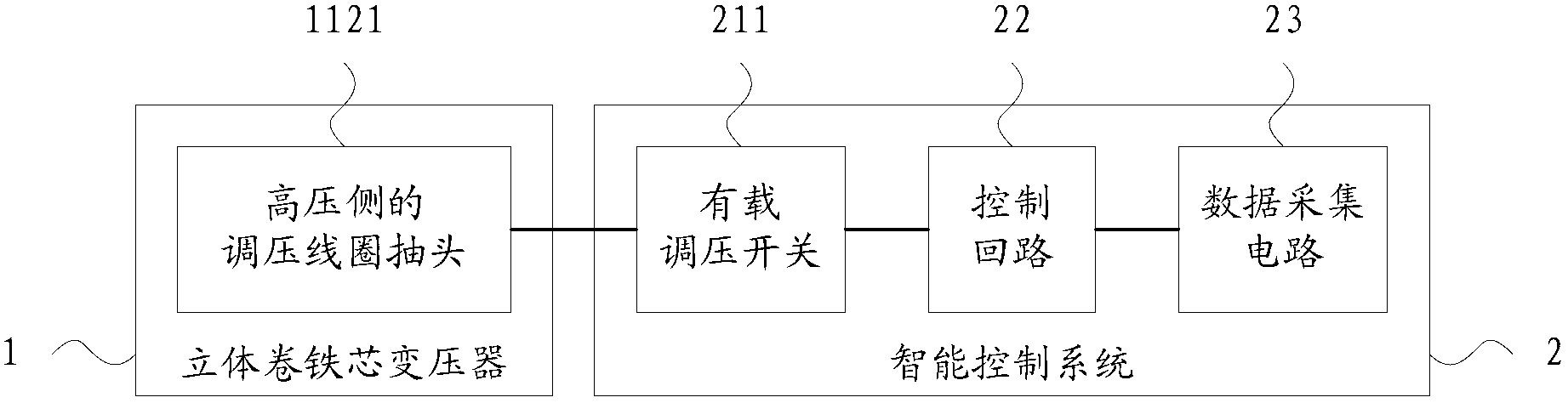

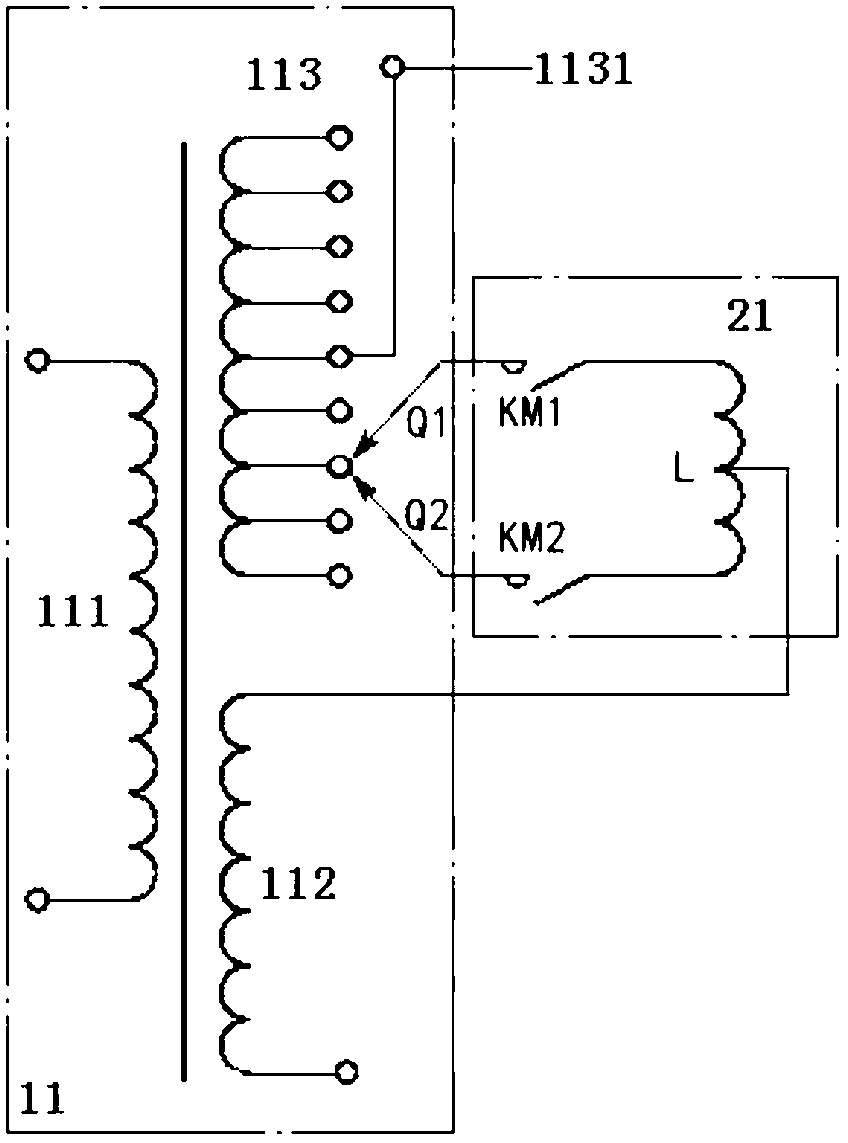

[0040] refer to figure 1 , which is a system structure diagram of a three-dimensional wound core intelligent transformer of the present invention. The three-dimensional wound core intelligent transformer of the present invention includes a three-dimensional wound core transformer 1 and an intelligent control system 2, wherein:

[0041] The intelligent control system 2 includes an on-load tap changer 211 , a control loop 22 and a data acquisition circuit 23 .

[0042] The voltage regulation coil tap 1121 on the high voltage side of the three-dimensional wound core transformer 1 is connected to the on-load tap changer 211 , the on-load tap changer 211 is connected to the control loop 22 , and the control loop 22 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com