Ballast fixing device and ballast assembly

A technology for fixing devices and ballasts, which is applied to the components of lighting devices, lighting devices, circuit layout, etc., can solve problems such as broken bone and left and right displacement of ballasts, so as to achieve reliable fixation and ensure safety , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

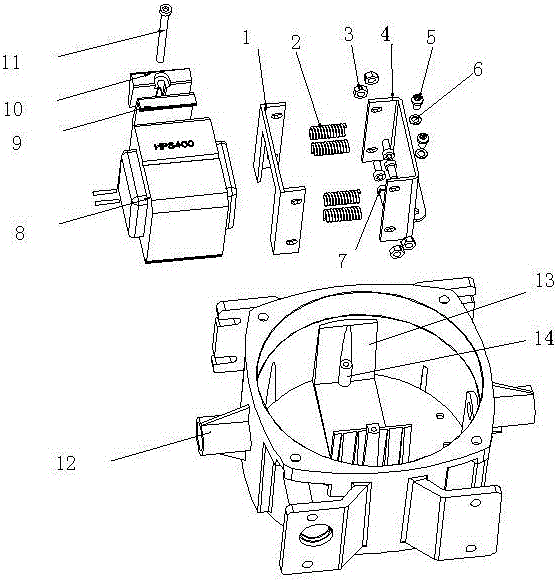

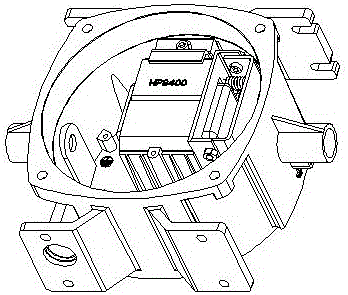

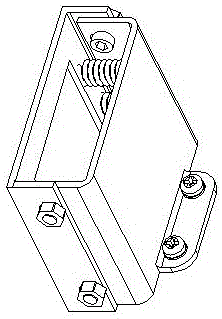

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0023] Please also refer to figure 1 and figure 2 , a ballast fixing device provided in a specific embodiment of the present invention. It should be noted that the front, rear, left, and right directions mentioned in the present invention are defined by the front, rear, left, and right directions in which the ballast is in working state, that is, under normal circumstances, the side of the ballast fixing device that is adjacent to the installation surface (wall surface) is The back is opposite to the front, so as to determine the front, rear, left, and right directions of the ballast and its fixing device.

[0024] Such as figure 1 As shown, the ballast fixing device includes: a ballast box body 12, a square groove member 13 for placing and fixing the ballast 8 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com