Mechanical arm device for power transformer maintenance

A technology of power transformers and manipulators, which is applied in the direction of manipulators, claw arms, manufacturing tools, etc., can solve the problems of large workload, long power failure time, and small available space of the hanging cover, and achieve improved detection brightness, enhanced mechanical strength, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

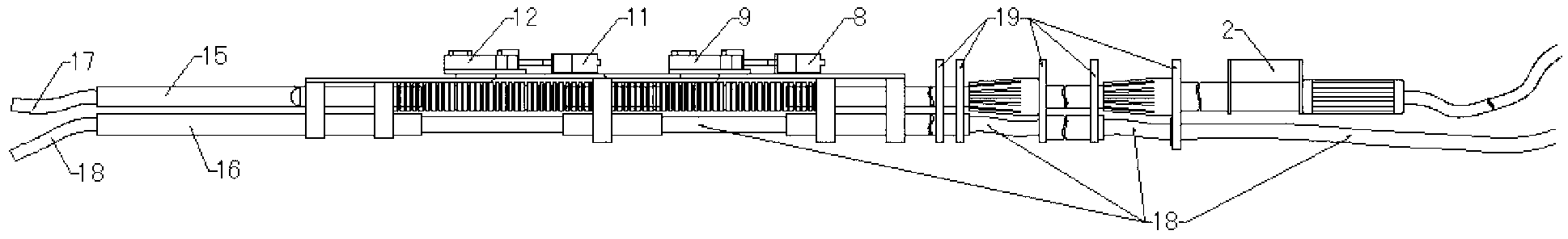

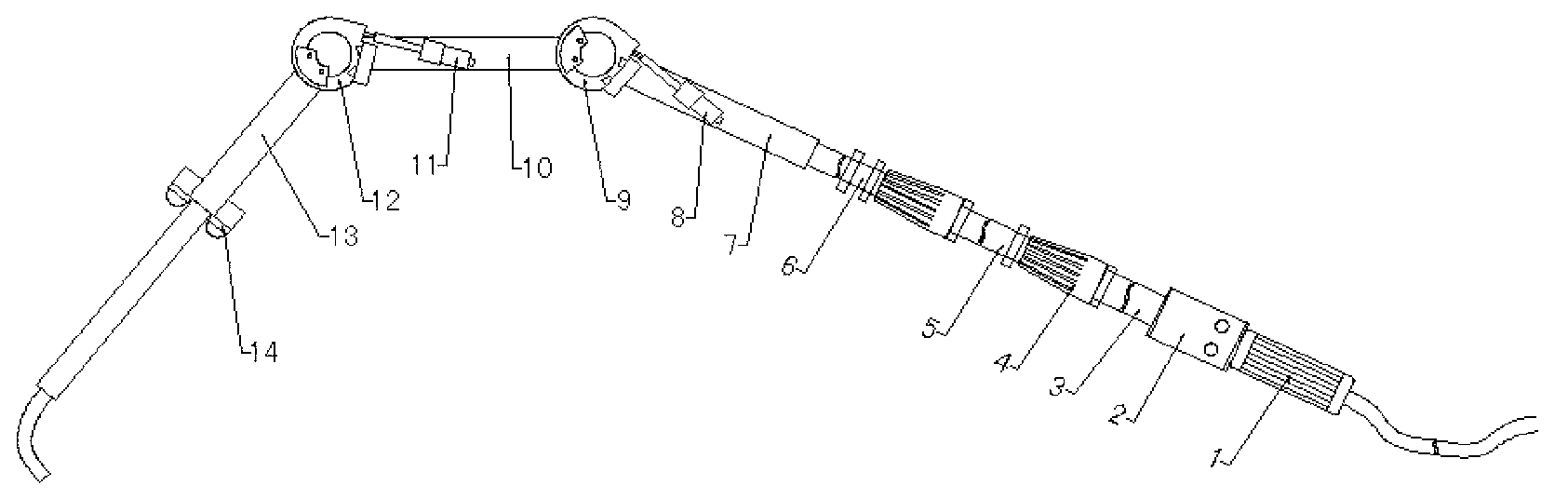

[0025] like figure 1 and figure 2 As shown, a mechanical arm for power transformer maintenance, which includes a telescopic rod assembly, a first joint assembly, a second joint assembly and an extension arm connected sequentially from the rear end to the front end, as well as lighting LED14, control switch 2, endoscope 17 and flush oil pipe 18. The extension arm includes an upper extension arm 15 and a lower extension arm 16, which respectively correspond to the double-hole structure inside the mechanical arm. Pass through the telescopic rod assembly, the second joint assembly, the first joint assembly, and then stretch out from the upper extension arm 15 and the lower extension arm 16 respectively. The lighting LED 14 is arranged at the front end of the mechanical arm, and as a probe lighting source, it can help the operator go deep into the equipment without light, and improve the detection brightness of the endoscope at the same time.

[0026] The telescopic rod assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com