Numerical control lathe with automatic punching device

A drilling device and CNC lathe technology, applied in the direction of feeding device, boring/drilling device, drilling/drilling equipment, etc., can solve the problems of easy burnout of the drill bit, low production efficiency, uneven feed speed, etc., and achieve Low labor intensity, high production efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

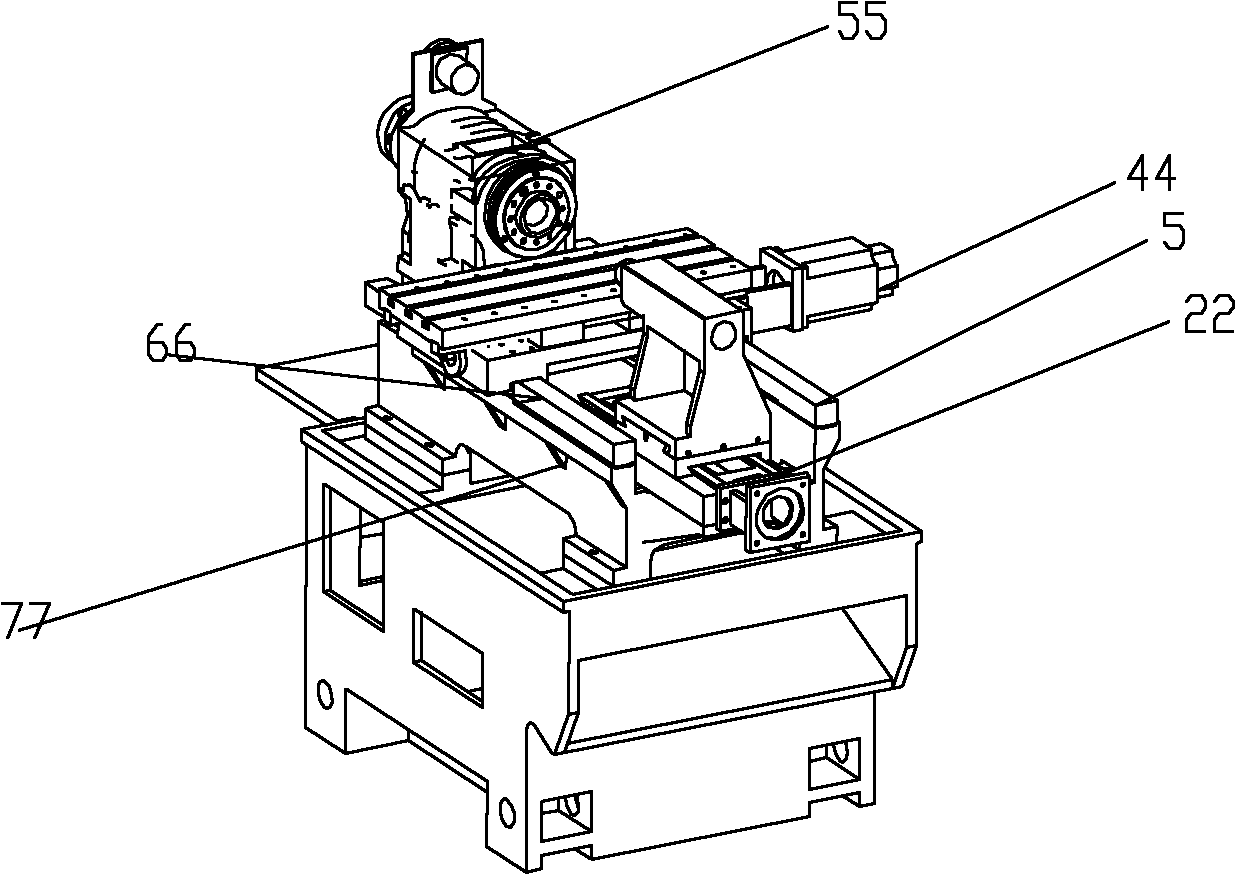

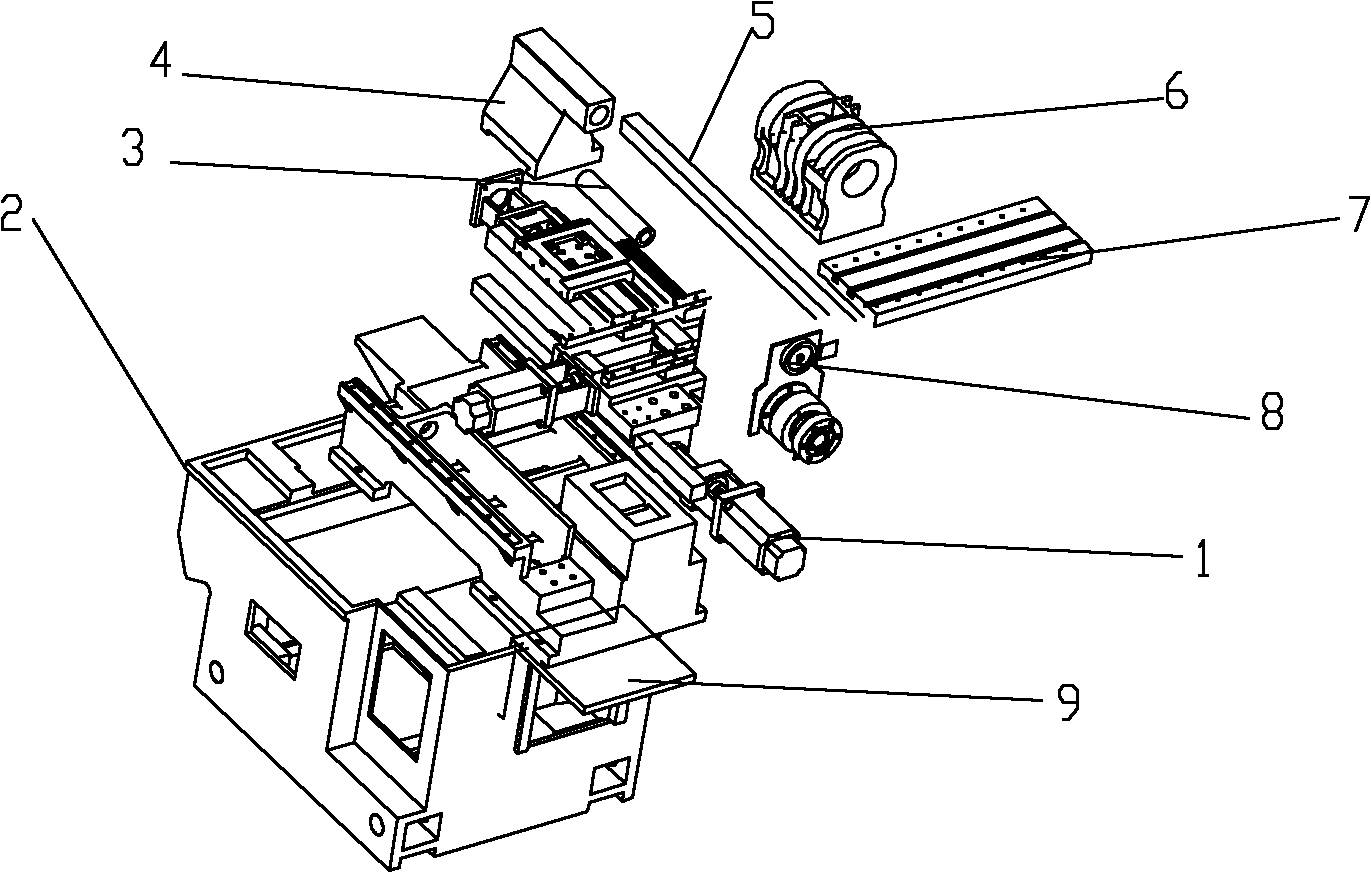

[0013] The present invention comprises machine base 2 and bed 77, and bed 77 one end is provided with tailstock 4, and the other end is provided with encoder seat 8, and tailstock 4 is mainly made up of tailstock body and tailstock sleeve 3, and tailstock passes tailstock The seat guide rail 5 is installed on the bed, and the tailstock sleeve 3 is installed in the round hole of the tailstock. The left and right linear guide rails 66 are arranged on the bed on both sides of the tailstock and the encoder seat 8, and a drag plate is arranged above the linear guide rail 66. The bed below the carriage is provided with a motor base 44, the top of the encoder base 8 is provided with a head box 6, the bed is provided with a motor base 55, the front end of the motor base is provided with a servo motor 1, and the middle part of the bed is provided with a slidable The small supporting plate 7, the tailstock guide rail 22 links to each other with the small supporting plate.

[0014] And b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com