Drawing method for hollow silicon core

A technology of hollow silicon core and manufacturing method, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of increased fracture or collapse of silicon cores, inability to grow silicon cores, and large impact of cracks, etc., and achieve artificial Comprehensive low cost, rapid growth, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

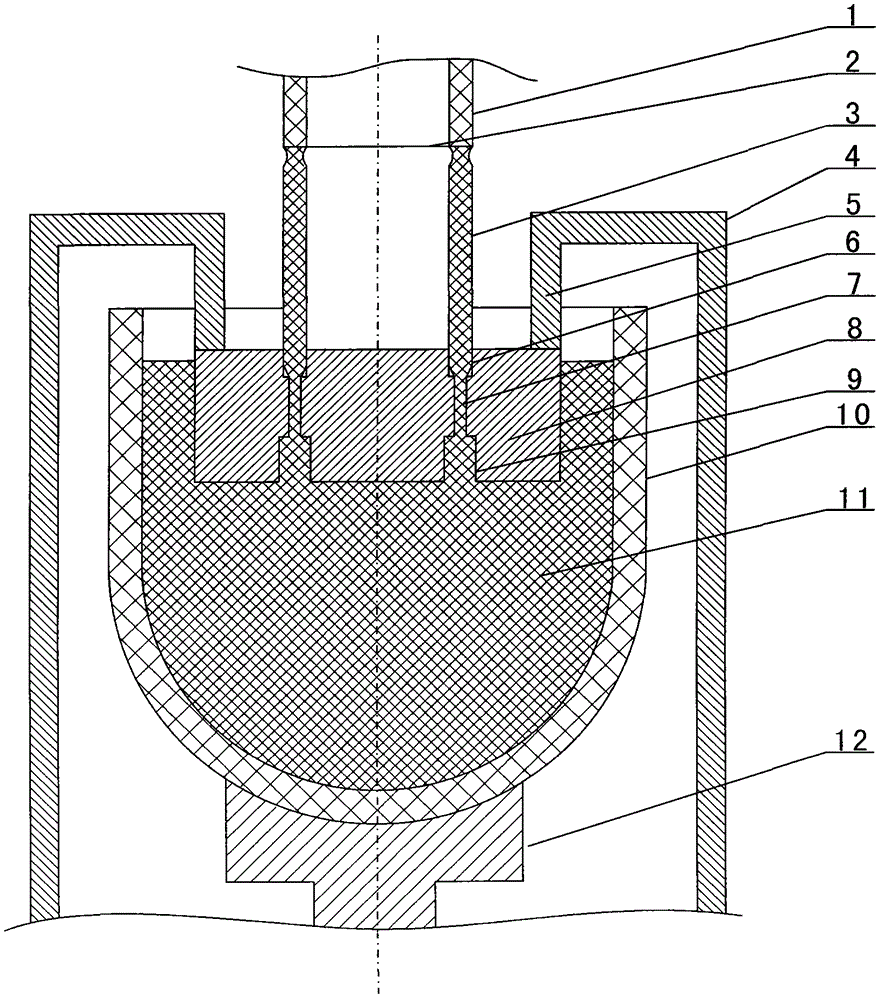

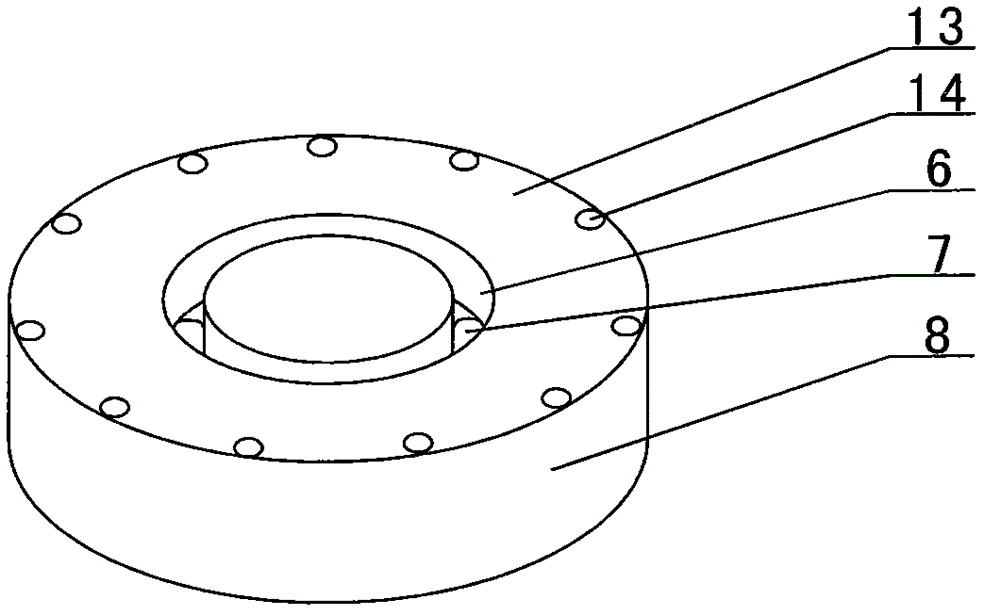

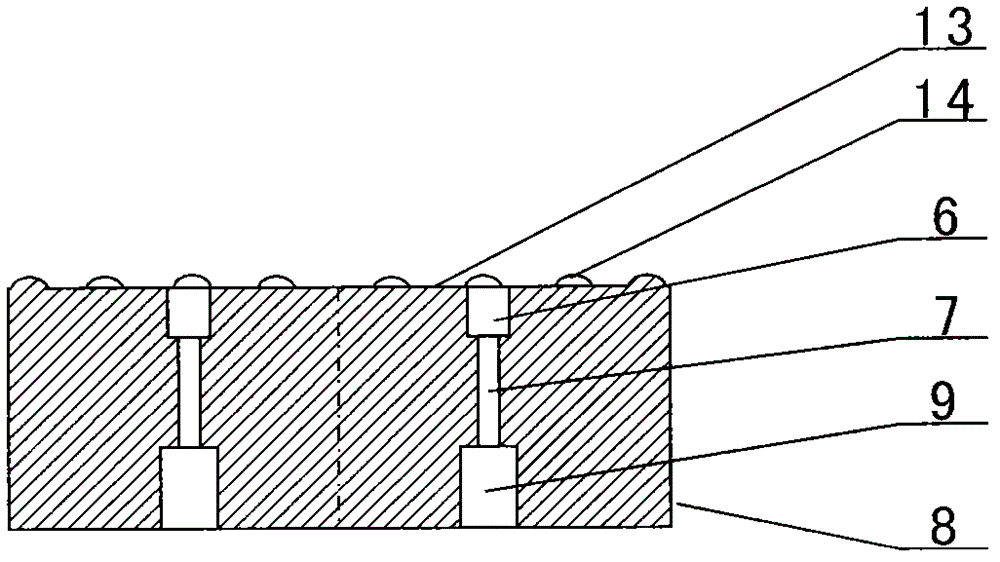

[0037] combined with figure 1 Or the drawing method of hollow silicon core described in 2 or 3, described drawing method comprises equipment, and described equipment comprises crucible 10 and heating mantle 4 for melting crystal 11; Die structure; the guide mode structure of the drawn tubular silicon core 3 is mainly used to realize the shape of the hollow silicon core; the crucible 10 and the heating jacket 4 for melting the crystal 11 are provided with heating at the outer interval of the crucible 10 Cover 4, the distance between the crucible 10 and the heating jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com