Fluorescence film for heat transfer printing on glass surface or ceramic surface and preparation method thereof

A technology of ceramic surface and thermal transfer printing, which is applied in the temperature recording method and other directions, and can solve the problems that new fluorescent products have not been developed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Preparation of transparent fluorescent material

[0051] Organic dyes and organic light-emitting small molecules containing unsaturated bonds can be synthesized by organic solvent synthesis, such as 7-(diethylamino)-4-methyl-2H-1-benzopyran-2-ketocoumarin 1. By selecting an appropriate solvent (for example, acetone, ethanol, etc.) or chemically changing the solvent affinity of the molecule, the organic molecule can be effectively dissolved in the solvent to form a completely colorless and invisible functional luminescent liquid. Down emits a striking characteristic light.

[0052] The obtained luminescent material can be applied to the field of anti-counterfeiting. It can not only make colorful patterns on the colorless and transparent medium, but also emit different lights from the same material under the excitation of different ultraviolet wavelengths, thus greatly improving the level of anti-counterfeiting. .

Embodiment 2

[0053] Embodiment 2: Preparation of transparent fluorescent gravure printing ink

[0054] Add the transparent fluorescent material prepared in Example 1 to the transparent gravure ink at a ratio of 1:50, and dissolve or fully disperse it to obtain a transparent fluorescent ink. The selected transparent ink itself should have printing properties on the PET surface. applicability.

Embodiment 3

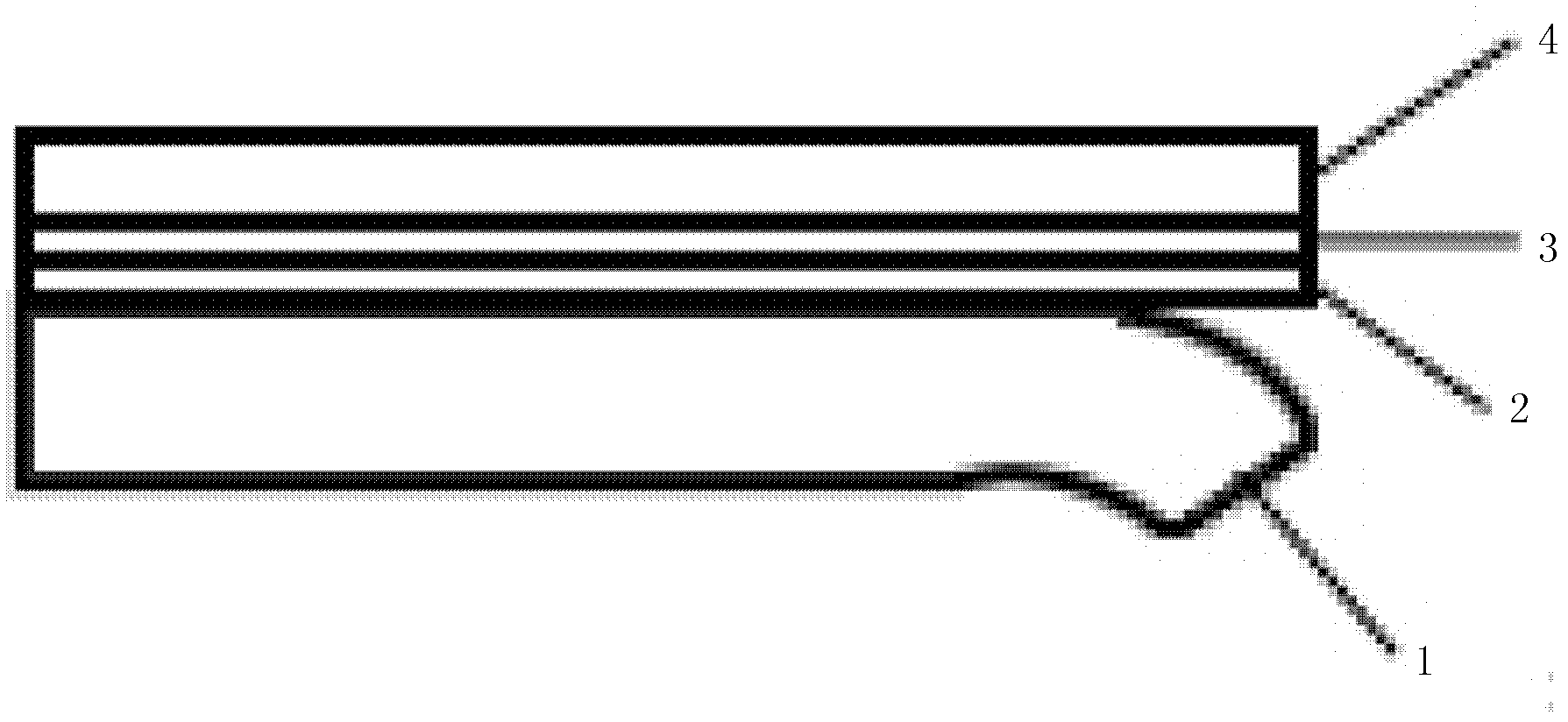

[0055] Embodiment 3: Preparation of fluorescent film for thermal transfer

[0056] The transparent fluorescent gravure printing ink that makes in embodiment 2 is printed on the PET film surface that has coated release layer by the mode of gravure printing, and the last gravure printing unit coats binder, and the final product is as follows: figure 1 As shown, a fluorescent film for thermal transfer printing was obtained, and the printing speed was controlled to be 40-70 m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com