Injection moulding machine

A technology for injection molding machines and connecting rods, applied in the field of injection molding machines, can solve problems such as difficult working space and cumbersome operations, and achieve the effect of easy balance adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

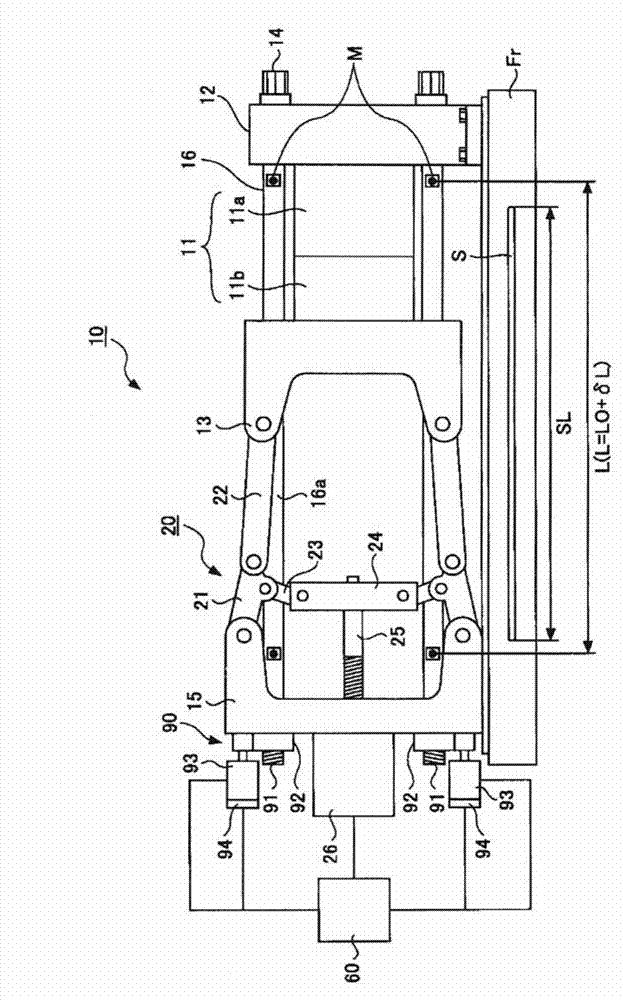

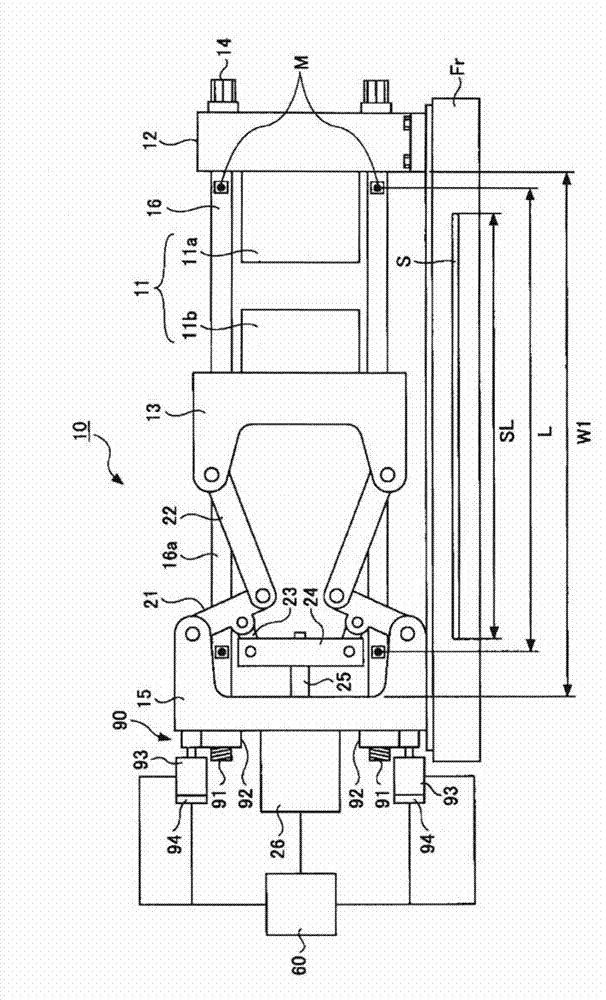

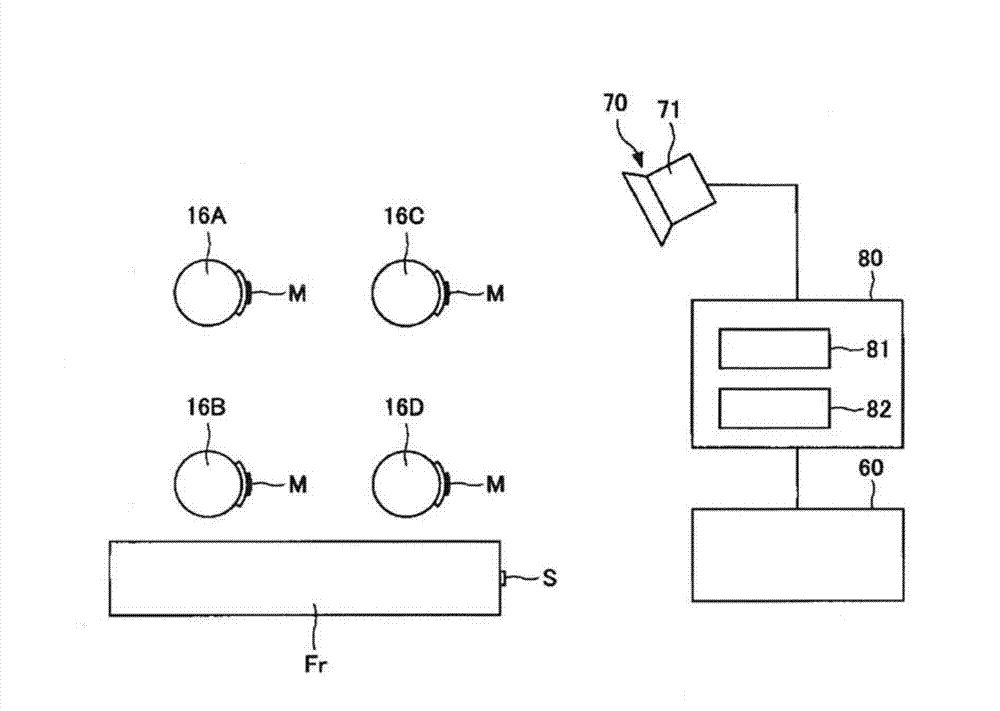

[0040] The injection molding machine of the present embodiment is provided with a mold clamping device using a motor and a toggle mechanism.

[0041] figure 1 It is a figure which shows the state at the time of mold closing of the injection molding machine of 1st Embodiment. figure 2 It is a figure which shows the state at the time of mold opening of the injection molding machine of 1st Embodiment.

[0042] The injection molding machine 10 includes: a fixed platen 12 to which a fixed mold 11a is mounted; a movable platen 13 to which a movable mold 11b is mounted; a toggle support 15 as a base member provided at a distance from the fixed platen 12; Multiple (for example, four) connecting rods 16 for fixing the pressing plate 12 and the toggle support 15 . The mold apparatus 11 is comprised by the fixed mold 11a and the movable mold 11b.

[0043] The fixed platen 12 is fixed to the frame Fr. A movable platen 13 is arranged opposite to the fixed platen 12 . A guide hole (no...

no. 2 Embodiment approach

[0110] The injection molding machine according to the first embodiment described above includes a mold clamping device using a motor and a toggle mechanism. On the other hand, the injection molding machine of this embodiment is different in that it is provided with a mold clamping device that uses a linear motor for the mold opening and closing operation and utilizes the attraction force of an electromagnet for the mold closing operation.

[0111] Figure 7 It is a figure which shows the state at the time of mold closing of the injection molding machine of 2nd Embodiment. Figure 8 It is a figure which shows the state at the time of mold opening of the injection molding machine of 2nd Embodiment.

[0112] The injection molding machine 110 includes: a fixed platen 112 to which a fixed mold 111a is mounted; a movable platen 113 to which a movable mold 111b is mounted; a rear platen 115 serving as a base member provided at a distance from the fixed platen 112; 112 and a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com