Fruit weighing and sorting system

A sorting system and weighing technology, which is applied in the field of agricultural machinery, can solve the problems of high labor cost, weighing and sorting accuracy and low degree of automation, and achieve labor cost saving, weighing and sorting accuracy and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

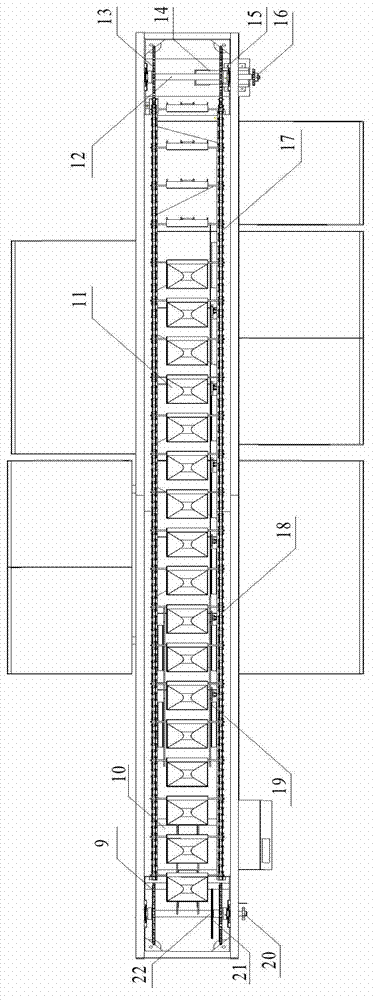

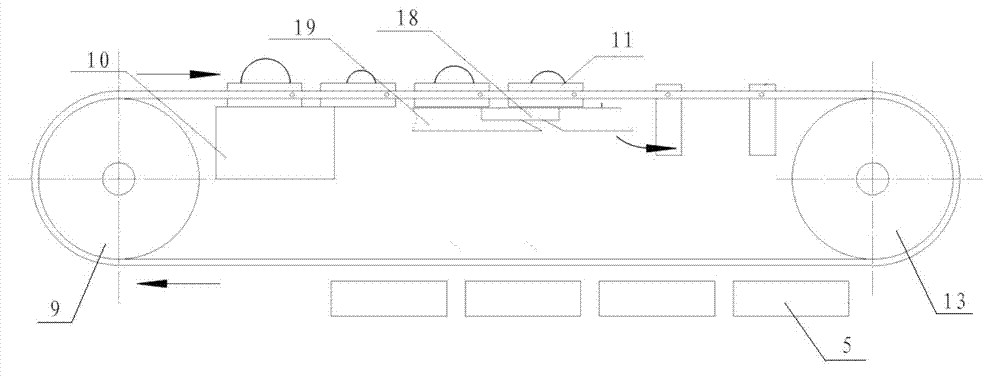

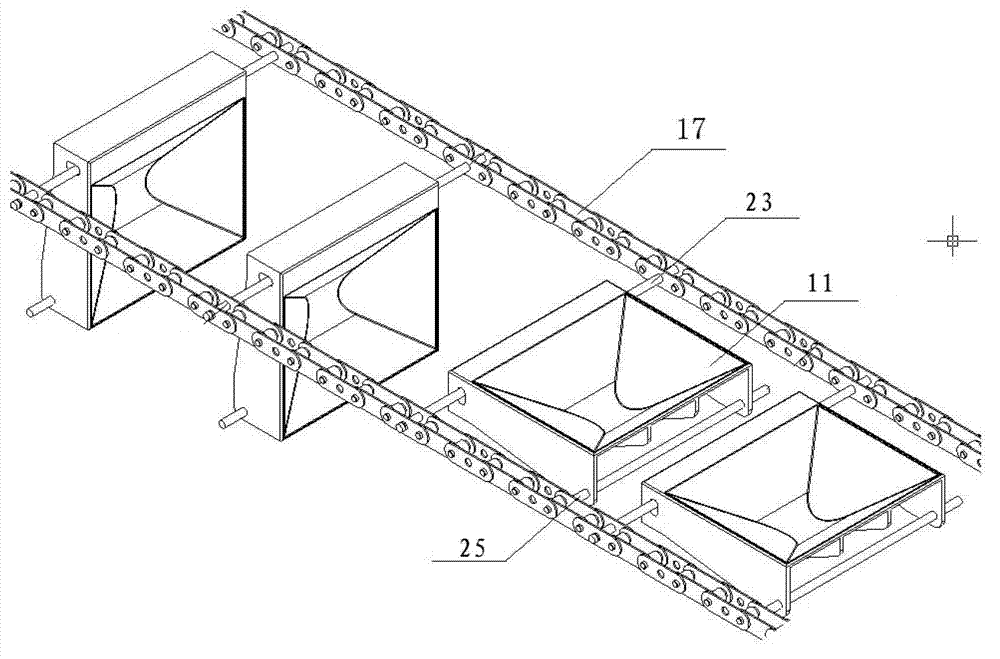

[0031] Such as figure 1 , figure 2 , image 3 and Figure 8 As shown, the fruit weighing and sorting system provided by the present invention comprises chain conveyor, fruit cup 11, running guide rail 19, weighing mechanism 10, unloading mechanism 18 and controller 3, and described chain conveyor has two Parallel chain 17, described fruit cup 11 comprises cup body, hinged shaft 23 and the long fruit cup shaft 25 that is arranged on the inverted end of described cup body, the hinged end of described cup body is connected with described chain by described hinged shaft 23 The two parallel chains 17 of the conveyor are connected and there is a gap that moves up and down betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com