Method for testing permeability characteristic of full-tailings cemented filling slurry

A technology of permeability characteristics and cemented filling, which is used in permeability/surface area analysis, measurement device, suspension and porous material analysis, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

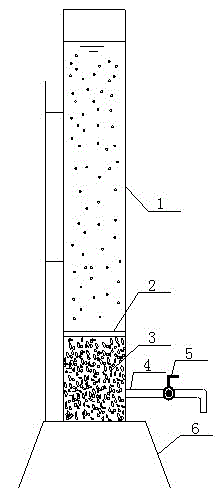

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below through embodiment.

[0014] In the embodiment, the test personnel follow a certain interval ( , , ,… ) Use a graduated cylinder to measure the amount of permeated water ( , , ,… ), combined with the infiltration water ( , , ,… ) and the length and width of the square section of the cuboid groove ( A , B ), to calculate the settlement height of seepage water ( , , ,… ); get what you get and Numerical fitting is performed to obtain and Relational function, further function derivation calculation, the filling slurry permeability characteristics can be obtained.

[0015] The present invention has many embodiments, the lime-sand ratio between cement and full tailings is 1:4, 1:5, 1:8, 1:10, 1:15 respectively, and the concentration after adding water is 65%, 68% , 72%, 75%.

[0016] get and The specific process of the relationship function:

[0017] (1) S=A×B

[0018] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com