Connector for connecting loading arm with tank truck

A technology for connectors and tank cars, which is applied in the direction of couplings, mechanical equipment, etc., can solve problems such as cumbersome operation, low safety, and low work efficiency, and achieve the effects of safe and reliable process, improved service life, and high degree of work automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, the connector for connecting the crane pipe and the tank truck according to the present invention includes a base 4 connected to the outrigger 14 of the crane pipe, axle lugs 3 evenly distributed and fixed along the outer edge of the base 4, The turntable 12 that is sleeved on the base 4 and rotatably connected with the base 4 has at least three lugs 3, and each lug 3 is respectively hinged with a claw for connecting the base 4 with the tank truck interface end 13 2.

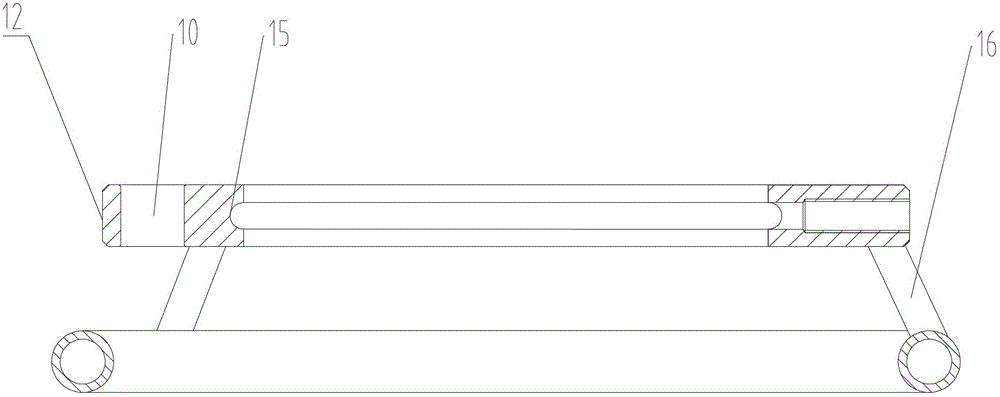

[0026] Such as figure 2 As shown, the turntable 12 is provided with a first annular groove 15 on the surface in contact with the base 4, and the base 4 is provided with a second annular groove on the surface in contact with the turntable 12, as figure 1 As shown, the first annular groove 15 and the second annular groove are combined into a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com