Method for reinforcing shallow part of mine shaft with long anchor cable

A long anchor cable and shaft technology, which is used in mining equipment, earthwork drilling, installation of bolts, etc., can solve the deformation and cracking of the support body and the wellbore, the difficulty of closing the support layer to resist pressure, and the lack of support strength, etc. It can solve the problem of cracking and damage, achieve good supporting effect and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] This embodiment takes the main return air shaft of the No. 2 mining area of Jinchuan Group Company as an example to illustrate the reinforcement process implemented by applying the method provided by the present invention.

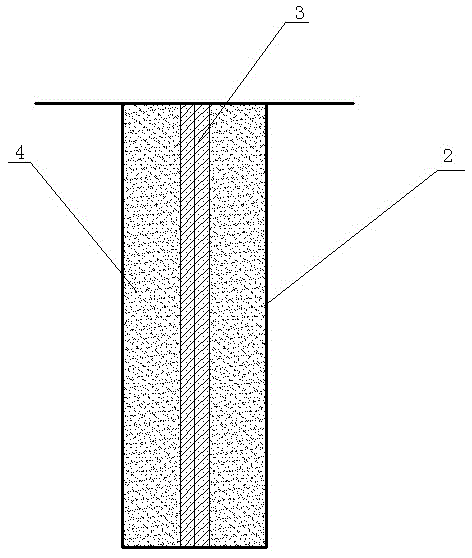

[0018] The shaft of the return air shaft has a net diameter of 6.5m and a depth of 720m. The wellbore of the return air shaft is located near the contact zone between the fault and the soft and hard rock formations, and the caving area is within 20m from the center of the wellbore. After using the anchor net plus concrete grouting method for support, the deformation and cracking of the support body appeared at 28m, 60m, 90m, and 125m of the wellbore. It was decided to adopt the reinforcement method provided by the present invention. The specific steps are as follows:

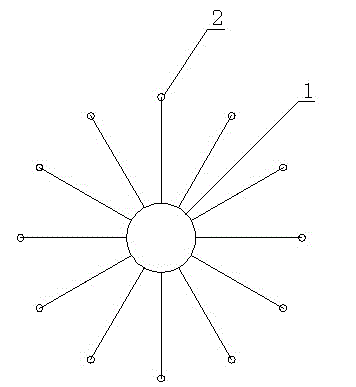

[0019] (1) Drilling: Set 12 drilling points evenly on a circle with the center of the return air shaft as the center and a radius of 12m, and drill holes at each drilling point to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com