Anchor member for emergency spillway scour prevention material

A technology for anchoring components and spillways, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of reduced pull-out effect, achieve the effect of increasing pull-out resistance, large pull-out force, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

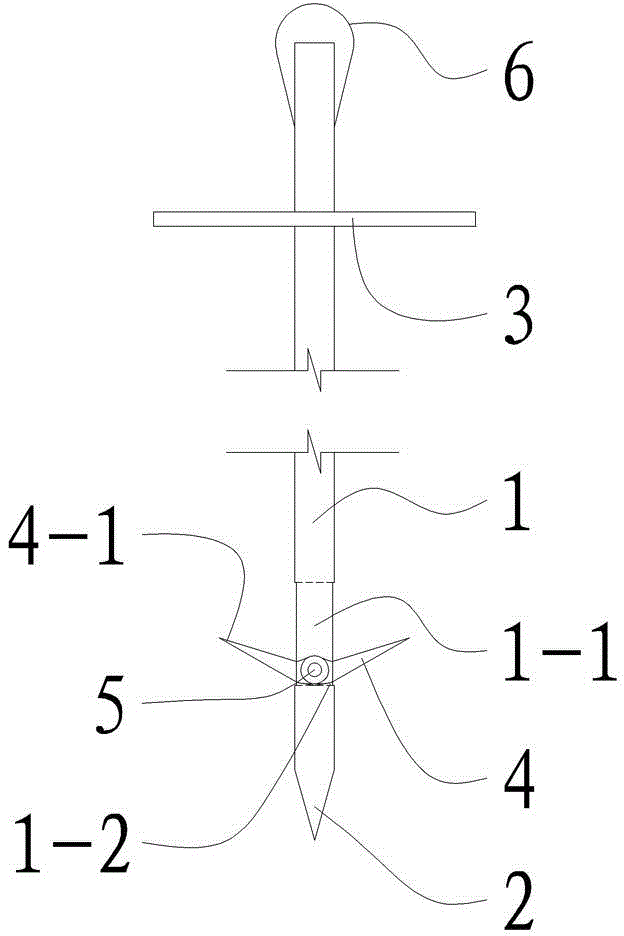

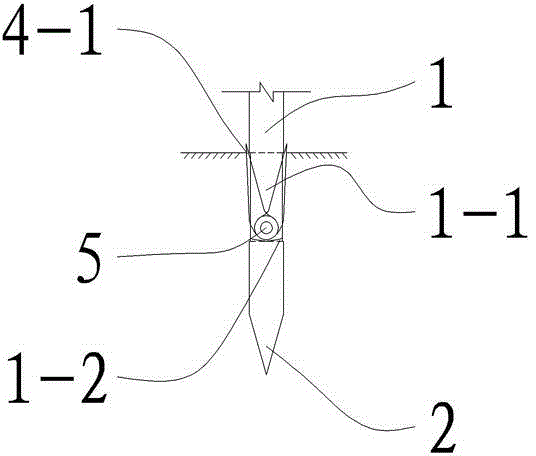

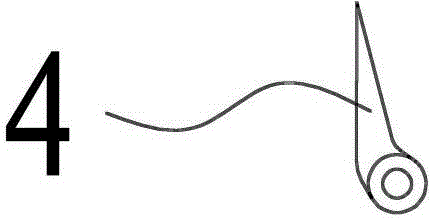

[0033] The anchor member used for the anti-scour material of the emergency spillway in this embodiment, such as figure 1 and figure 2 As shown, it includes a nail shank 1, a nail tip 2 arranged at one end of the nail shank and a nail head 3 arranged at the other end of the nail shank. At least one through hole 1-1 is formed in the middle of the nail shaft 1 . The through hole 1-1 is provided with a pair of V-shaped self-expanding thorns 4 hinged on the same axis 5, and the empty end 4-1 of the self-expanding thorns protrudes from the through hole 1-1.

[0034] When the anchoring member is nailed into the soil, a pair of self-expanding thorns 4 rotate towards each other and approach each other and the empty end 4-1 of the self-expanding thorn leans against the nail rod 1 obliquely; when the anchoring member is pulled up from the soil At this time, a pair of self-expanding thorns 4 counter-rotate away from each other and the empty end 4-1 of the self-expanding thorns leaves t...

Embodiment 2

[0044] The anchor member used for the anti-scour material of the emergency spillway in this embodiment is basically the same as that in Embodiment 1, as Figure 6 and Figure 7As shown, except that it is the same as the first embodiment, the difference is: a spring 7 is connected between a pair of self-expanding thorns 4, and a pair of self-expanding thorns is bound with a rope 8. When the rope 8 is tied tightly, a pair of self-expanding thorns 4 overcome the spring force and move closer to each other; when the rope 8 is untied, a pair of self-expanding thorns 4 are separated from each other under the action of the spring force.

[0045] During actual use, the anchoring member is knocked into the soil first, and when the empty end 4-1 of the self-expanding thorn of the anchoring member is about to be buried in the soil, the rope 8 is untied, and then the anchoring member is continued to be rammed into the soil to automatically The hollow end 4-1 of the expanded thorn does les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com