Preparation method of polyurethane energy-absorbing material

An energy-absorbing material, polyurethane technology, applied in the field of polyurethane energy-absorbing material preparation, can solve the problems such as difficult control of isopropanol volatilization, side reactions, etc., achieve good shear thickening performance and increase complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of polyurethane energy-absorbing material (one-step preparation process)

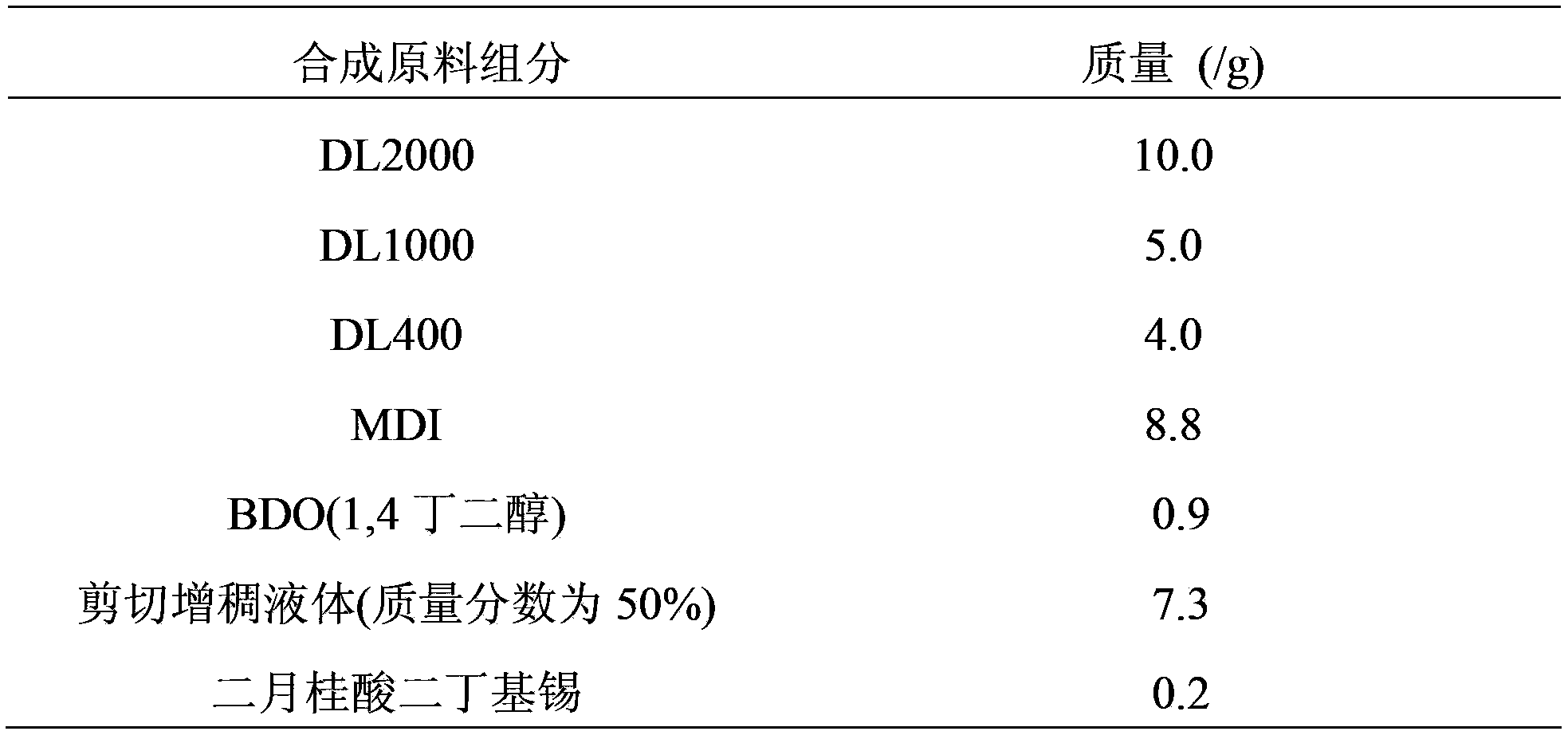

[0040] Table 1. Components and contents of raw materials for polyurethane energy-absorbing materials (n -NCO / n -OH =1.05)

[0041]

[0042] (1) Weigh polyoxypropylene diols DL2000, DL1000, DL400 (Shandong Dongda-Nuowei Polyurethane Co., Ltd.), respectively, with a mass of 10.0g, 5.0g, and 4.0g (component A) and add them to the single-necked flask in, stir evenly;

[0043] (2) Dissolve borated silicone polymer (Dow Corning Silicone Co., Ltd., brand name DC3179) in hydroxyl silicone oil (Zhonghao Chenguang Chemical Research Institute, brand name GY-209) at 80°C for 3 hours. The shear thickening liquid that obtains mass fraction is 50%; Take 7.3g mass fraction and be the shear thickening liquid of 50%, it is joined in the polyoxypropylene glycol three-component system in single-necked flask, stirs this System for 30 minutes to mix evenly;

[0044] (3) Weigh 8.8g of c...

Embodiment 2

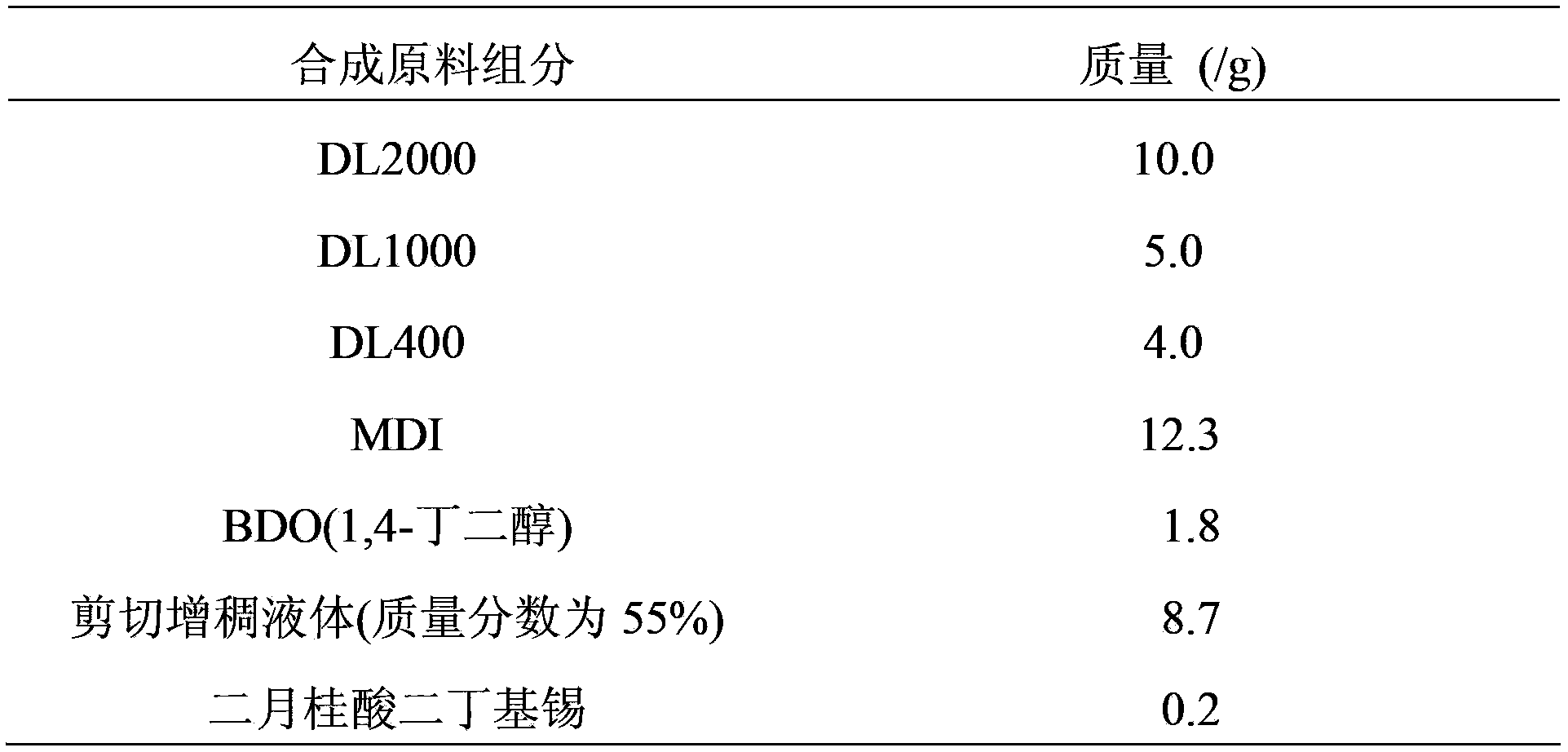

[0048] Table 2. Components and contents of polyurethane energy-absorbing materials (n -NCO / n -OH =1.1)

[0049]

[0050] (1) Weigh polyoxypropylene diols DL2000, DL1000, DL400 respectively, with masses of 10.0g, 5.0g, and 4.0g (component A) (Shandong Dongda-Nuowei Polyurethane Co., Ltd.) and add them to the single-necked flask in, stir evenly;

[0051] (2) Dissolve borated silicone polymer (Dow Corning Silicone Co., Ltd., brand name DC3179) in hydroxyl silicone oil (Zhonghao Chenguang Chemical Research Institute, brand name GY-209) at 80°C for 3 hours. The shear thickening liquid that obtains mass fraction is 55%; Take 8.7g mass fraction and be the shear thickening liquid of 55%, it is joined in the polyoxypropylene glycol three-component mixing system in single-necked flask, stirs The system was mixed for 30 minutes until uniform;

[0052] (3) Weigh 12.3g of MDI (component B) (Huntsman Company of the United States) and add it to the above-mentioned system after stirr...

Embodiment 3

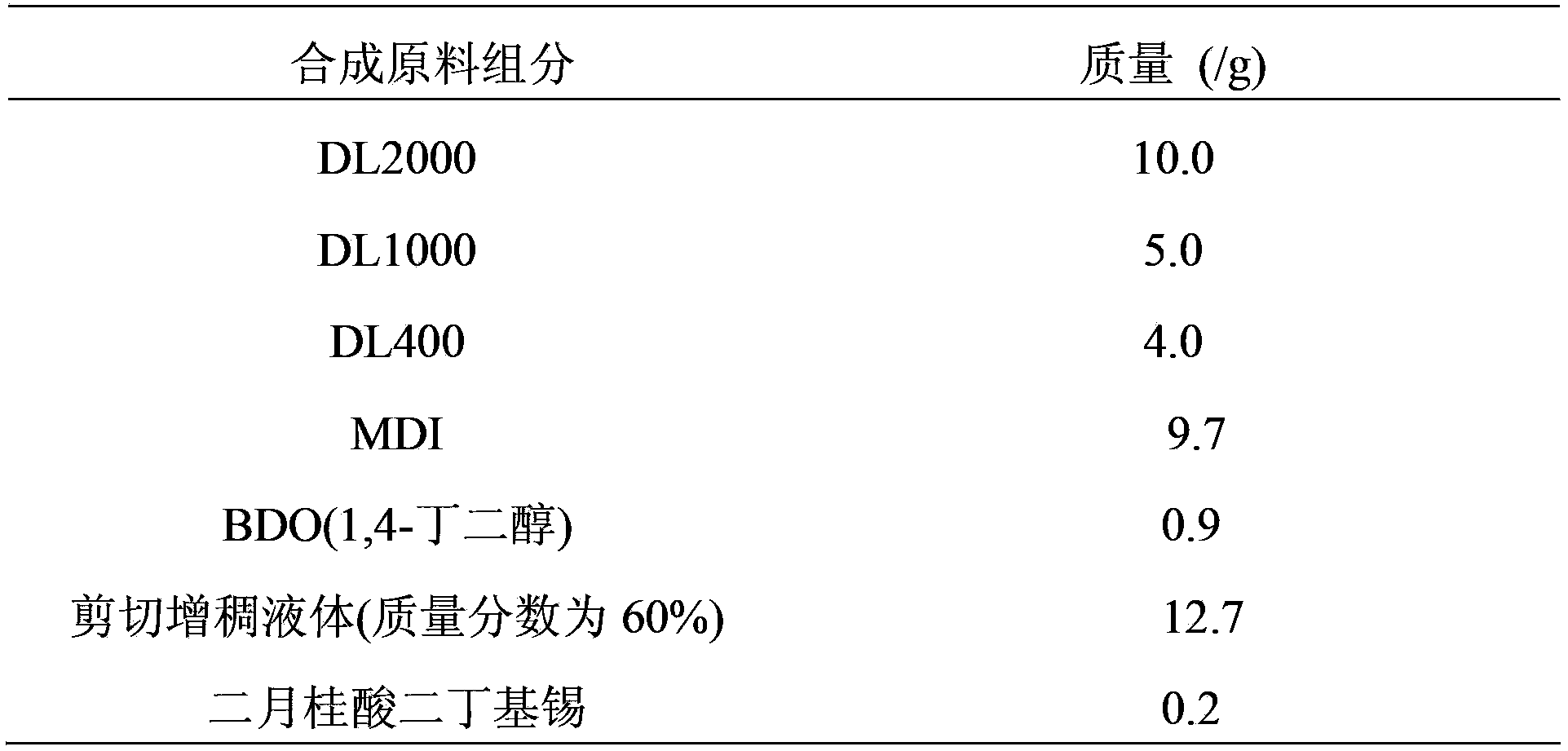

[0056] Table 3. Components and contents of polyurethane energy-absorbing materials (n -NCO / n -OH =1.15)

[0057]

[0058] (1) Weigh polyoxypropylene diols DL2000, DL1000, DL400 respectively, with masses of 10.0g, 5.0g, and 4.0g (component A) (Shandong Dongda-Nuowei Polyurethane Co., Ltd.) and add them to the single-necked flask in, stir evenly;

[0059] (2) Dissolve borated silicone polymer (Dow Corning Silicone Co., Ltd., brand name DC3179) in hydroxyl silicone oil (Zhonghao Chenguang Chemical Research Institute, brand name GY-209) at 80°C to obtain a mass fraction of 60 % shear thickening liquid; Weigh 12.7g mass fraction of 60% shear thickening liquid, add it to the three-component mixing system of polyoxypropylene glycol in the single-necked flask, stir the system for 30min to mix Uniform;

[0060] (3) Weigh 9.7g of MDI (component B) (U.S. Huntsman Company) and add it to the above-mentioned system after stirring evenly, and stir for 30 minutes until the mixture is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com