Manufacture method of low-stress polarization maintaining optical fibre applied to coupling

A polarization-maintaining optical fiber and a technology of a manufacturing method, which are applied in the field of communication, can solve problems affecting device performance, changes in extinction ratio indicators, and degradation of polarization-maintaining optical fiber polarization-maintaining performance, and achieve the effect of increasing the fixed strength and reducing the impact of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to better understand the present invention, the implementation manner of the invention will be described in detail below in conjunction with specific examples and accompanying drawings.

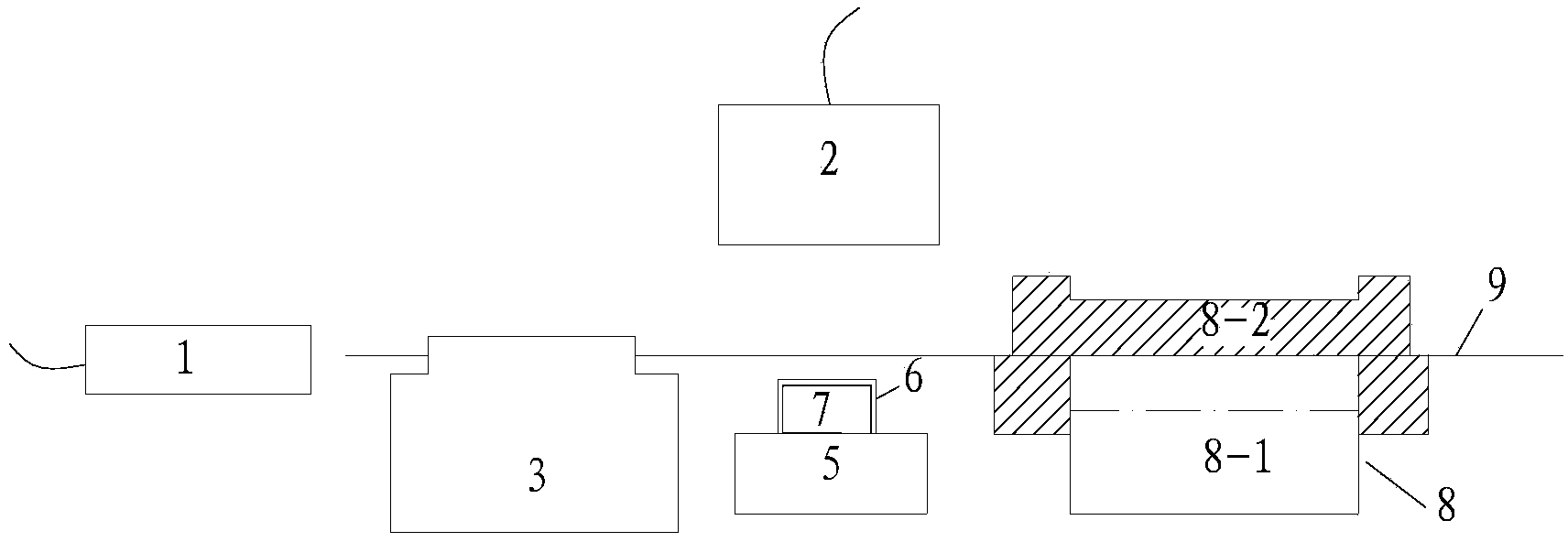

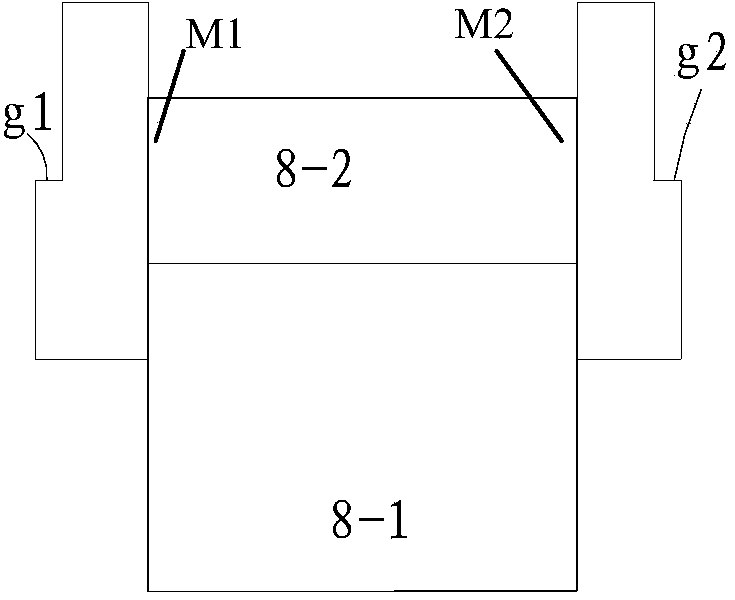

[0061] Such as figure 1 The shown includes a first image detection device 1 and a second image detection device 2, a bare polarization-maintaining optical fiber limit assembly 3, a three-dimensional motion fine-tuning table 5, an adhesive coating member 6, a polarization-maintaining optical fiber fixing groove 7, a polarization-maintaining optical fiber The polarization-maintaining fiber rotation assembly 8, the first image detection device 1 is placed at the front end of the polarization-maintaining fiber to detect the pattern of the end face of the fiber, the second image detection device 2 is placed above the three-dimensional motion fine-tuning table 5, and the polarization-maintaining fiber 9 includes the polarization-maintaining fiber stripping The coating layer part 9-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com