Hydraulic grab driven by diesel through wireless remote control

A technology of radio remote control and hydraulic grab bucket, applied in the direction of load hanging components, transportation and packaging, can solve problems such as hidden safety hazards, inability to grasp goods, and economic loss of cables to enterprises, achieve convenient operation, and solve the problem of large heat generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

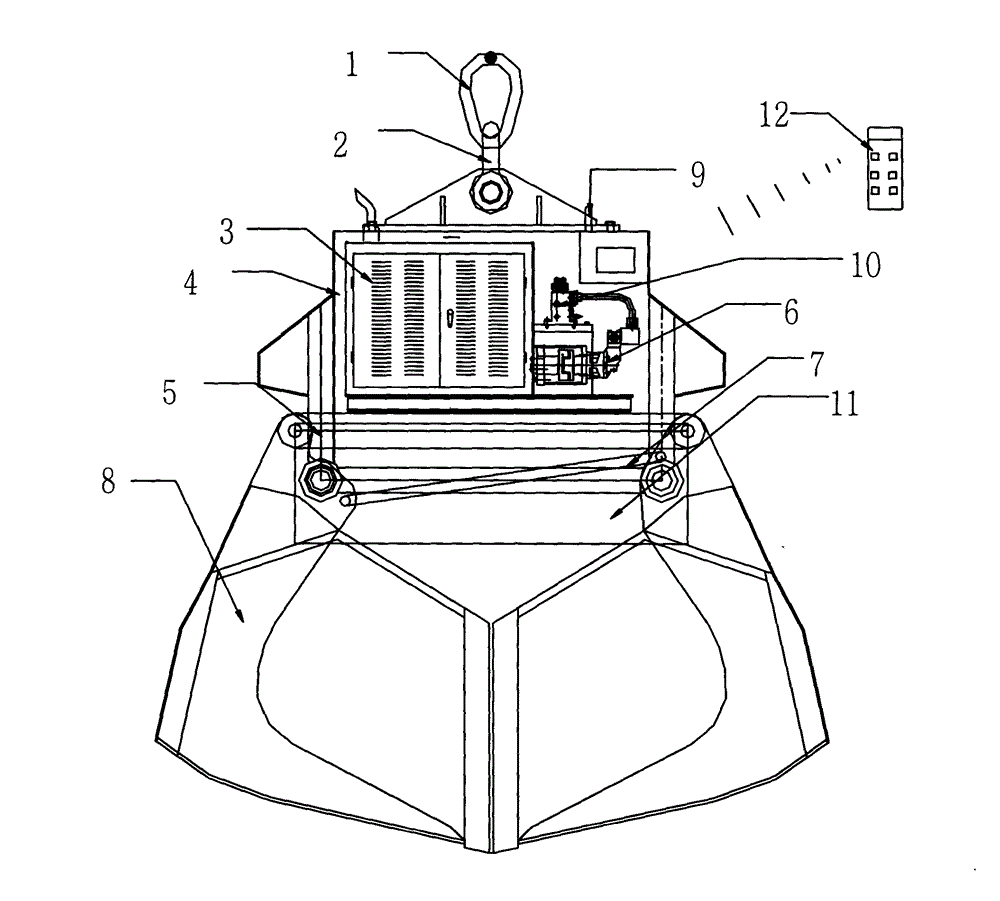

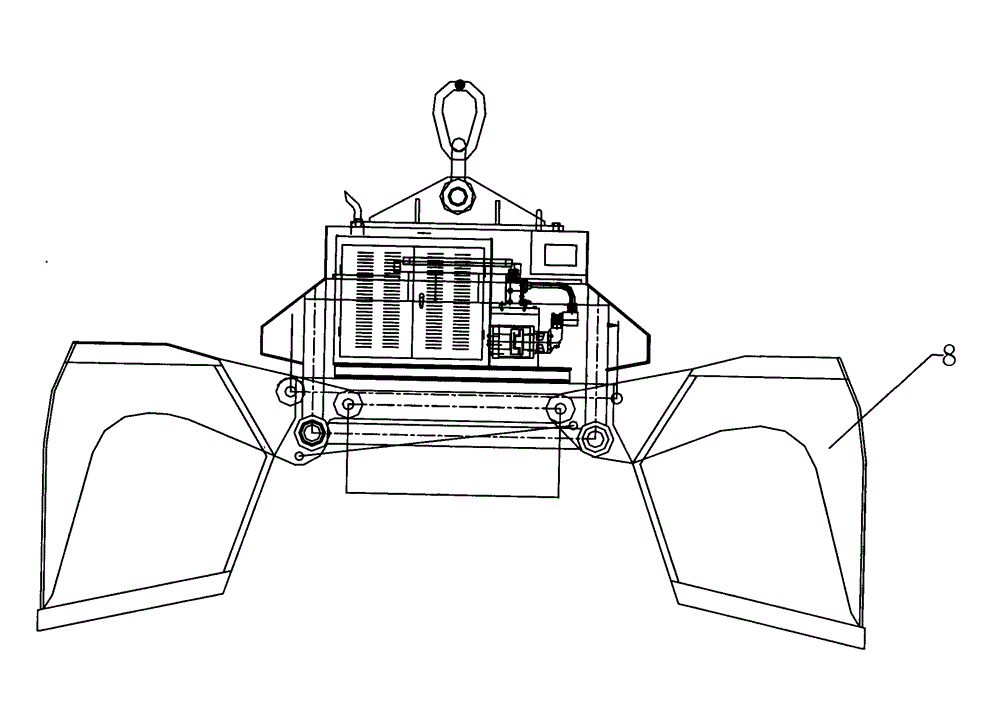

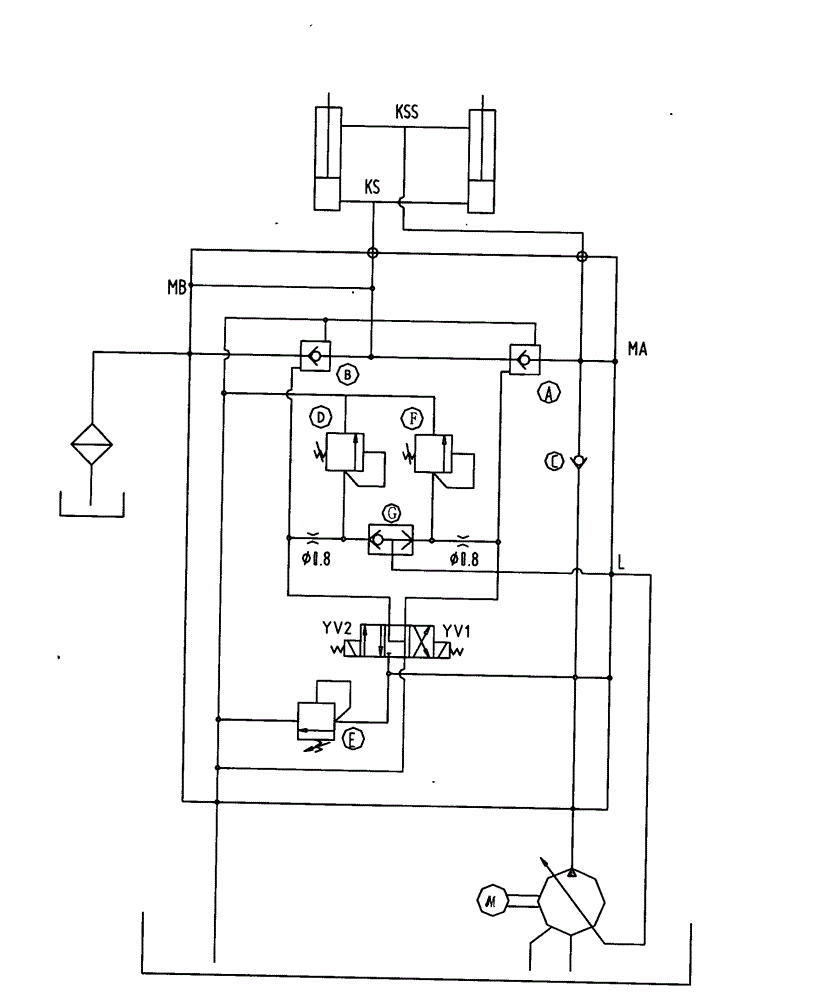

[0016] see Figure 1 to Figure 3 , in order to achieve the above object, the present invention adopts the following technical solutions to achieve: a radio remote control diesel engine driven hydraulic grab, including ring 1, shackle 2, shell 4, lower bolster 11, bucket body 8, hydraulic device, radio Remote control device, the hydraulic grab also includes a connecting rod 7, the connecting rod 7 acts as a limiter for the bucket body when the bucket body 8 completes the opening and closing action, and the hydraulic device is provided with a hydraulic pump 6, an oil cylinder 5. Control valve block system 10, the hydraulic pump 6 is powered by the diesel engine 3 connected to it and drives the oil cylinder 5 through a solenoid valve, the remote contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com