Method and device for ink-jet printing on curved container surfaces

An inkjet printing, container technology, used in printing, power transmission devices, transfer materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

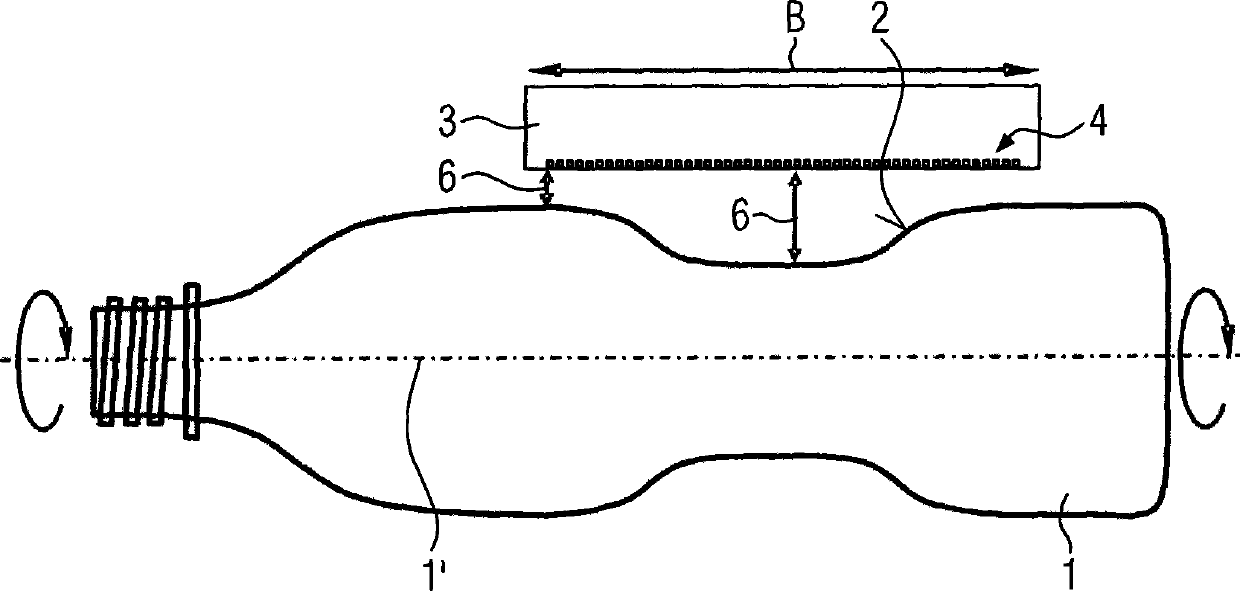

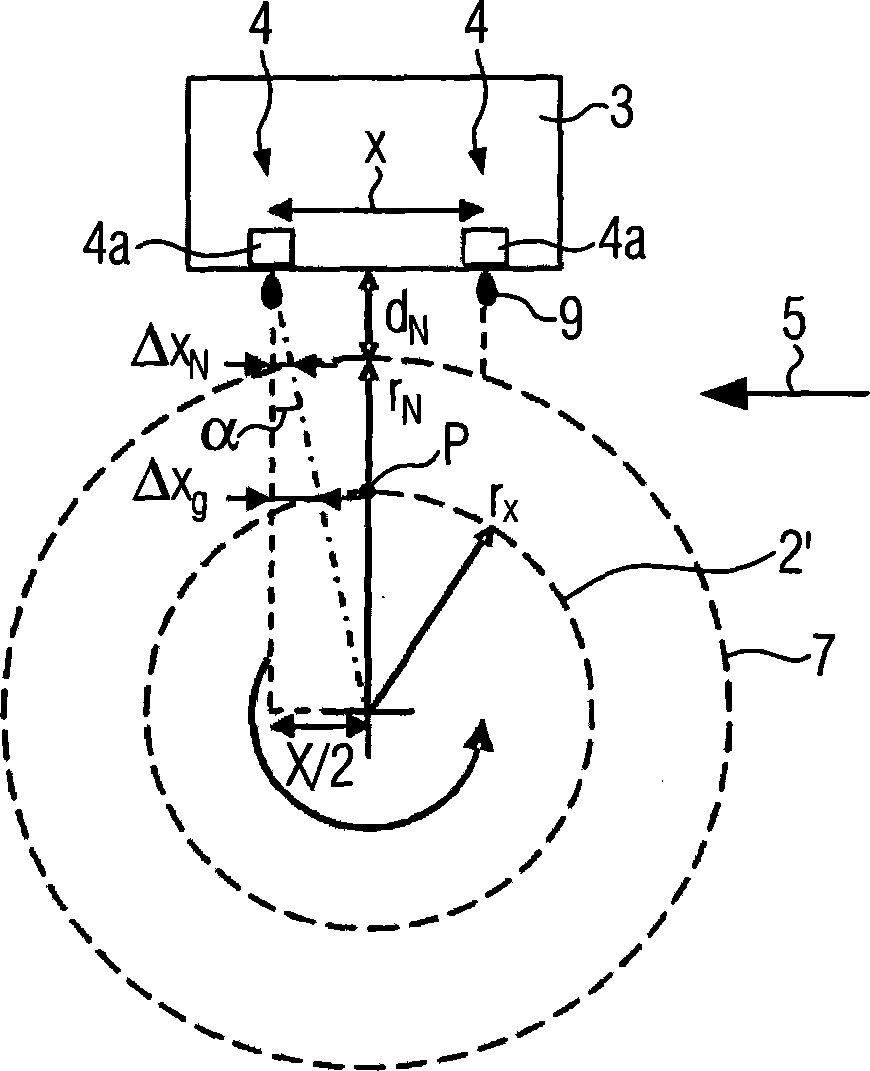

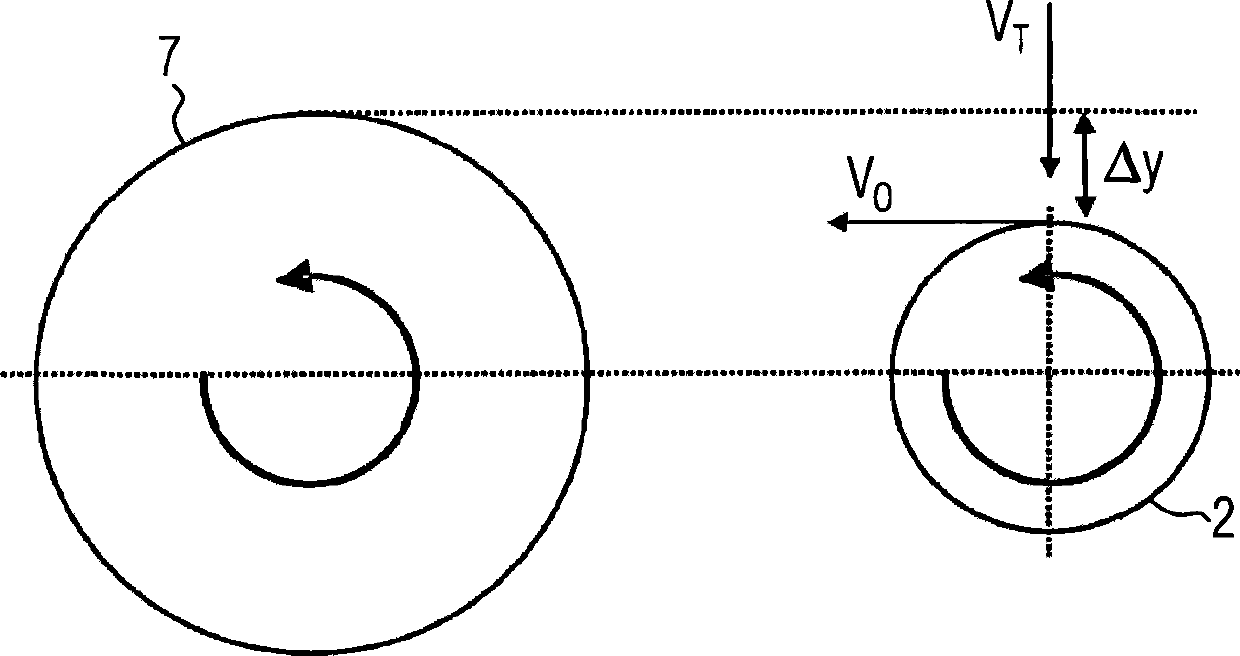

[0037] next reference figure 1 with 2 A preferred embodiment of the method according to the invention for inkjet printing on containers 1 , such as beverage bottles, is described. However, this method is also generally suitable for printing other objects with curved surfaces. Surfaces of this type 2 in figure 1 Schematically indicated in is a section of the side wall of the container 1 . The surface 2 is positioned rotatably about the main axis 1' of the container 1 in front of the printing head 3 of the row 4 of nozzles. In this case, the printing press with the corresponding nozzle row 4 and the positioning unit for carrying out the printing movement between the printing head 3 and the surface 2 to be printed can be arranged in a known manner. According to the invention, these positioning units are combined with a control unit (not shown) and / or an evaluation unit in order to carry out the printing timing of the nozzle row 4 and / or the nozzles 4a arranged thereon in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com