Ventilation dust-removing cutting platform

A cutting platform, ventilation and dust removal technology, applied in the direction of smoke removal, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of high energy consumption, no measures for smoke and dust, and poor dust suction effect, etc., to achieve simple structure and high efficiency Good, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings.

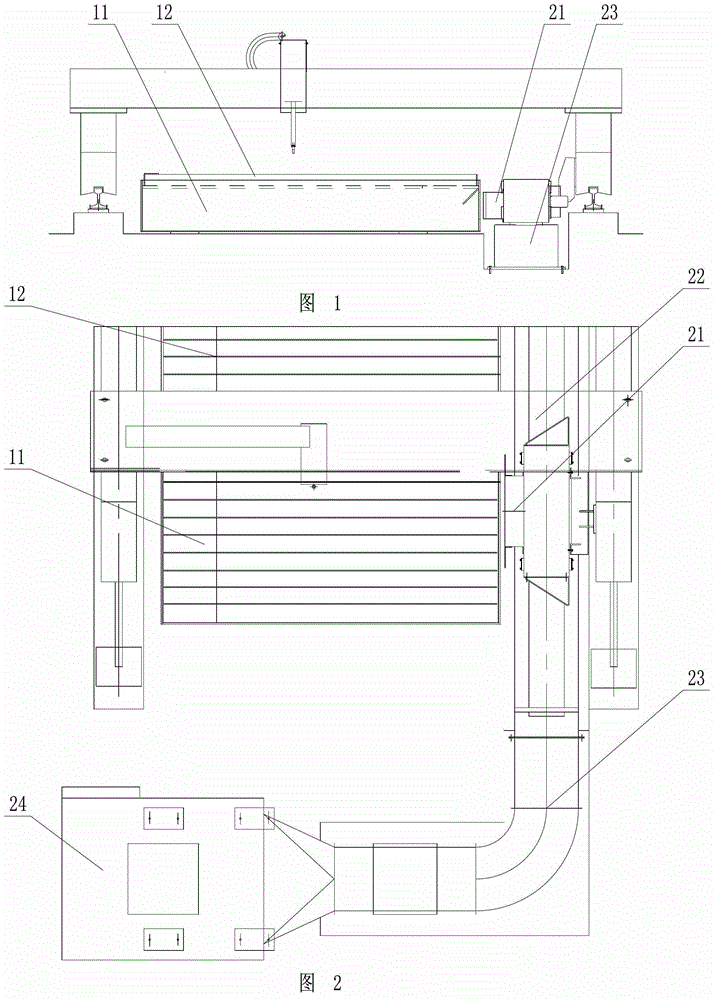

[0011] Such as Figure 1 ~ Figure 2 As shown: the air extraction and dust removal cutting platform includes a bellows 11, a material rack 12, a suction port 21, a sealing belt 22, an air duct 23, a dust collector 24, and the like.

[0012] The present invention includes a cutting table and an extraction system such as figure 1 As shown, the cutting table is composed of several bellows 11 arranged side by side and a rack 12 positioned on the upper surface of the bellows 11. The inner cavity of the bellows 11 forms several dust suction chambers arranged side by side. The upper part of the bellows 11 is open. A small suction port is respectively arranged on one side of each bellows 11;

[0013] Such as figure 2 As shown, the exhaust system includes a suction port 21 positioned at one side of the small suction port of the bellows 11, an air duct 23 and a dust collector 24, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com