Cigar coat forming machine

A cigar wrapper and molding machine technology, which is applied in the manufacture of cigars, applications, tobacco, etc., can solve the problems of limited production efficiency, high failure rate, complex structure, etc., and achieves the effects of flexible operation, reasonable structure and high control precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

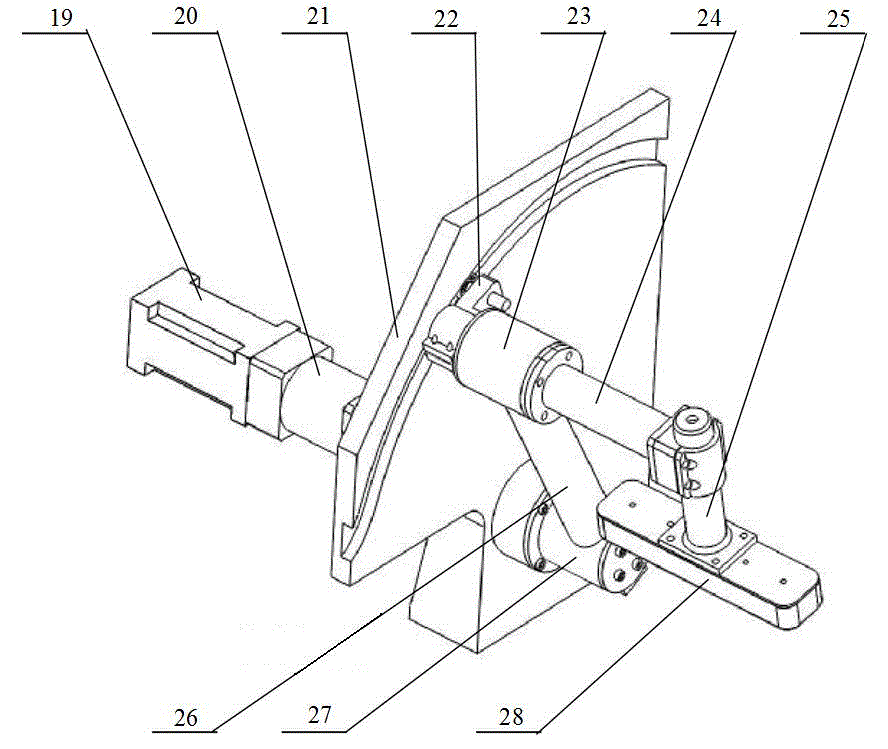

[0026] Such as figure 1 As shown, the rolling mechanism 4, the film transfer mechanism 3, the winding mechanism 2, and the cutting mold mechanism 5 are installed on the machine base 1, the rolling mechanism 4 is installed above the cutting mold mechanism 5, and the film transfer mechanism is installed behind the cutting mold mechanism 5 Mechanism 3, the film-moving mechanism 3 is equipped with a winding mechanism 2, a cutting mold mechanism 5, a rolling mechanism 4, a film-moving mechanism 3, and a winding mechanism 2 are connected with a control mechanism to form a cigar wrapper forming machine.

[0027] Such as figure 2 As shown, the rolling mechanism 4 includes a rolling servo motor 6, a rolling reducer 7, a ball screw 12 and a rolling wheel 15, and two arms 18 are installed at intervals on the base 1, and the arms 18 are mounted on the bearings The ball screw 12 is installed on the seat 10, and one end of the ball screw 12 is connected to the rolling reducer 7 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com