Clutch device

A clutch device and clutch technology, applied in the direction of clutches, friction clutches, fluid-driven clutches, etc., can solve the problems of fixed force influence, lack of structural space for fixed parts, large structural space, etc., and achieve small size, less structural space, The effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

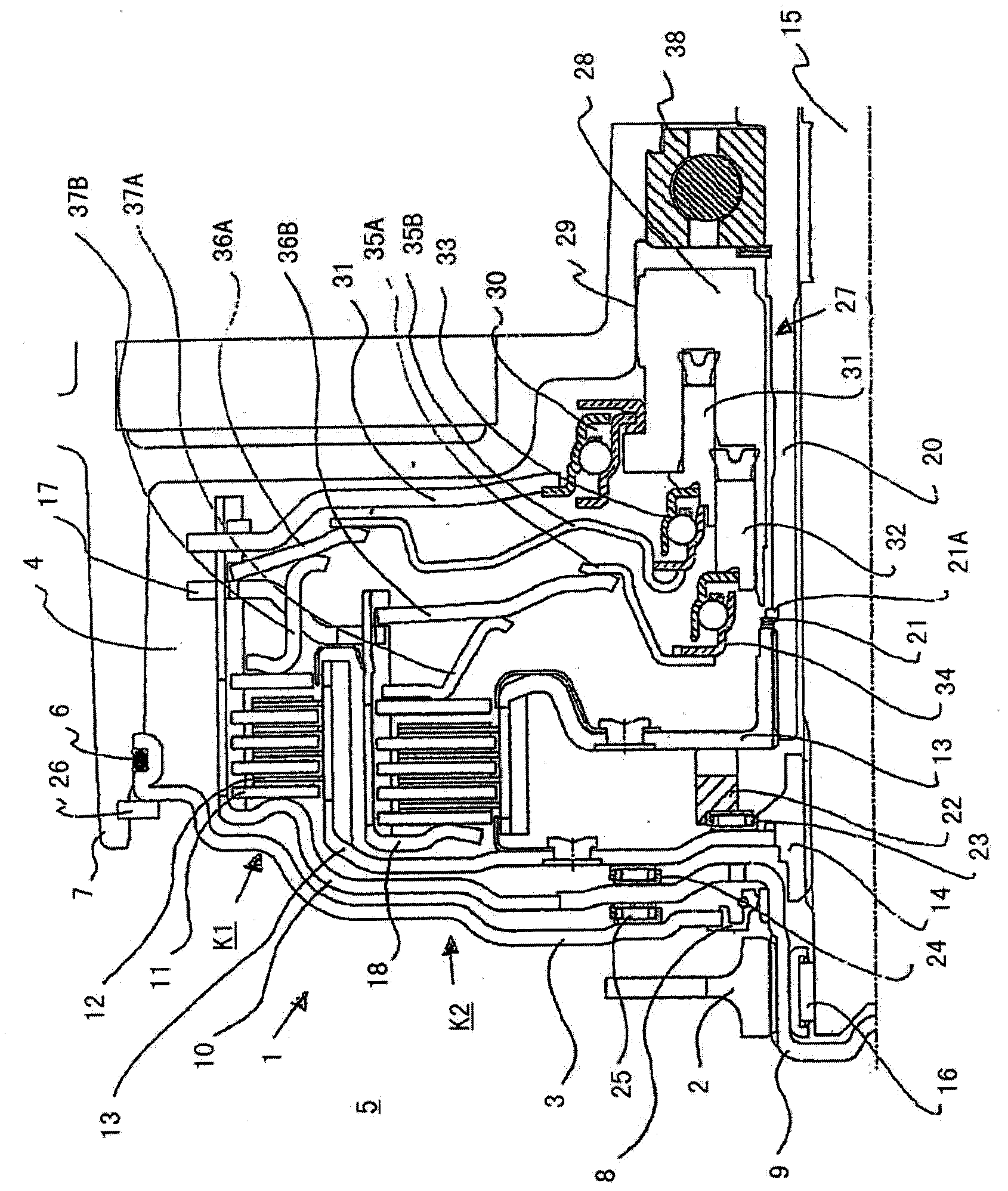

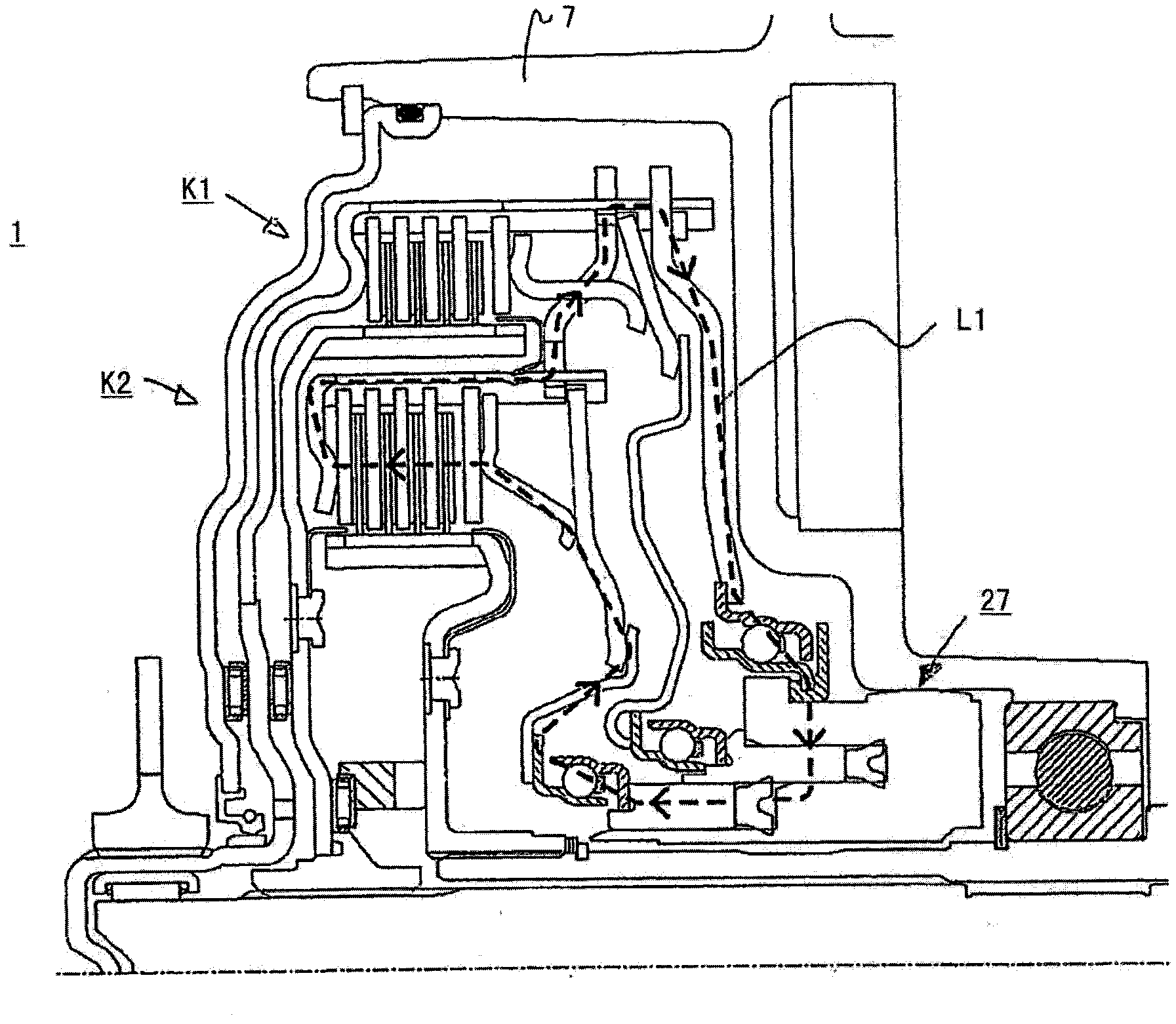

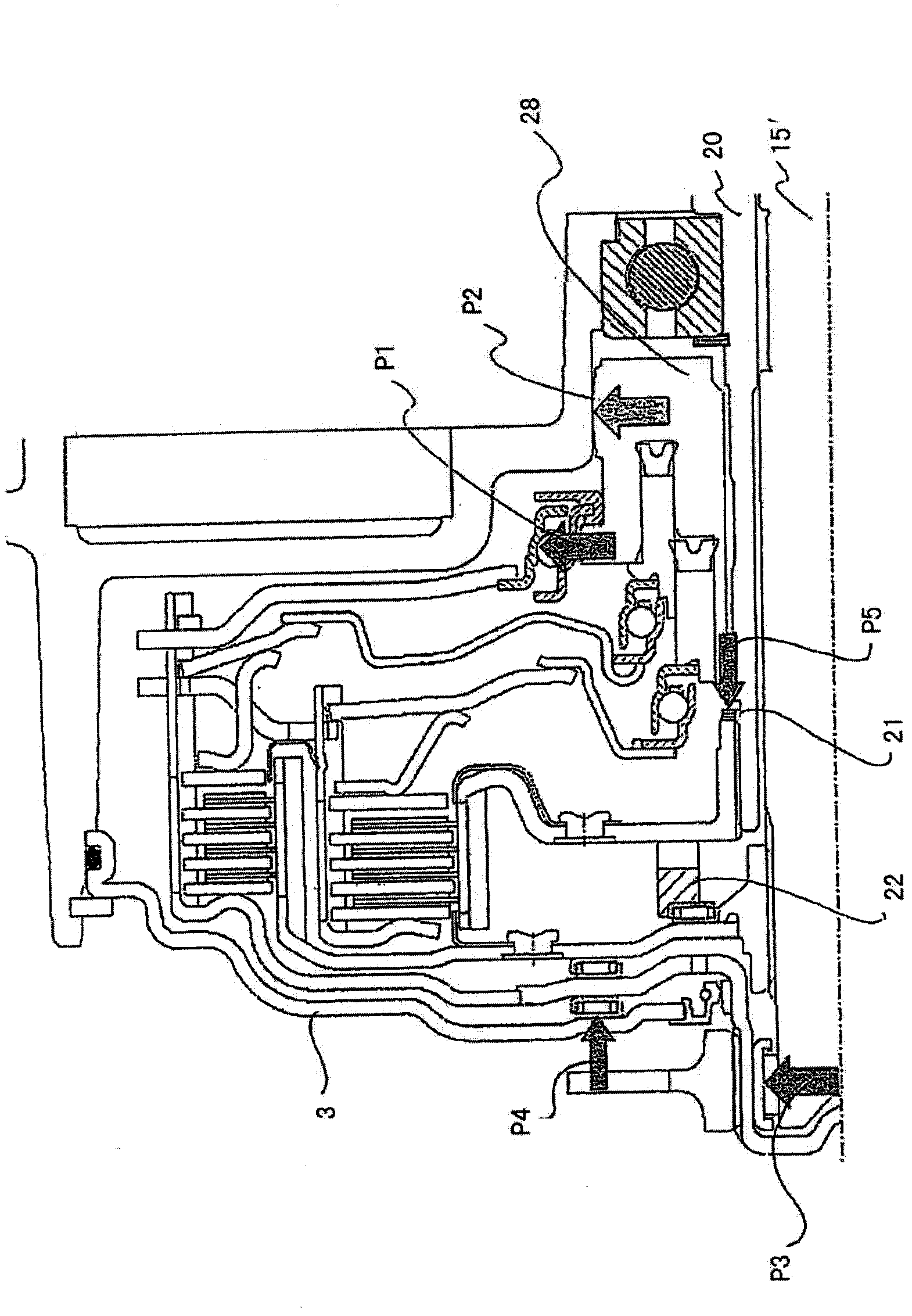

[0032] attached figure 1In the dual clutch 1 formed by two radially nested wet multi-plate clutches K1 and K2 shown, the clutch K1 is arranged radially outside, and the clutch K2 is arranged on the inside. The dual clutch 1 is driven by an output hub 2 of a dual-mass flywheel (not shown separately in the figure, hereinafter also referred to as ZMS) connected in front of the clutch 1 . The clutch cover 3 separating the wet chamber 4 from the dry chamber 5 is located between this dual mass flywheel (ZMS) and the dual clutch 1 . The static seal 6 is preferably realized by means of an O-ring 6 or another static sealing element on the clutch cover 3 towards the transmission housing 7 of the transmission (not shown separately) arranged downstream of the drive train. Sealing towards the dual clutch 1 is preferably effected via a radial shaft sealing ring 8 as dynamic sealing element.

[0033] The output hub 2 of the dual mass flywheel (ZMS) is non-rotatably connected to the clutch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com