Weight-pressing lever automatically controlling switch

A lever and switch technology, applied in electric switches, electrical components, circuits, etc., can solve the problems of switch floating bottle failure, easy burning, and hidden dangers, and achieve the effect of simple structure and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

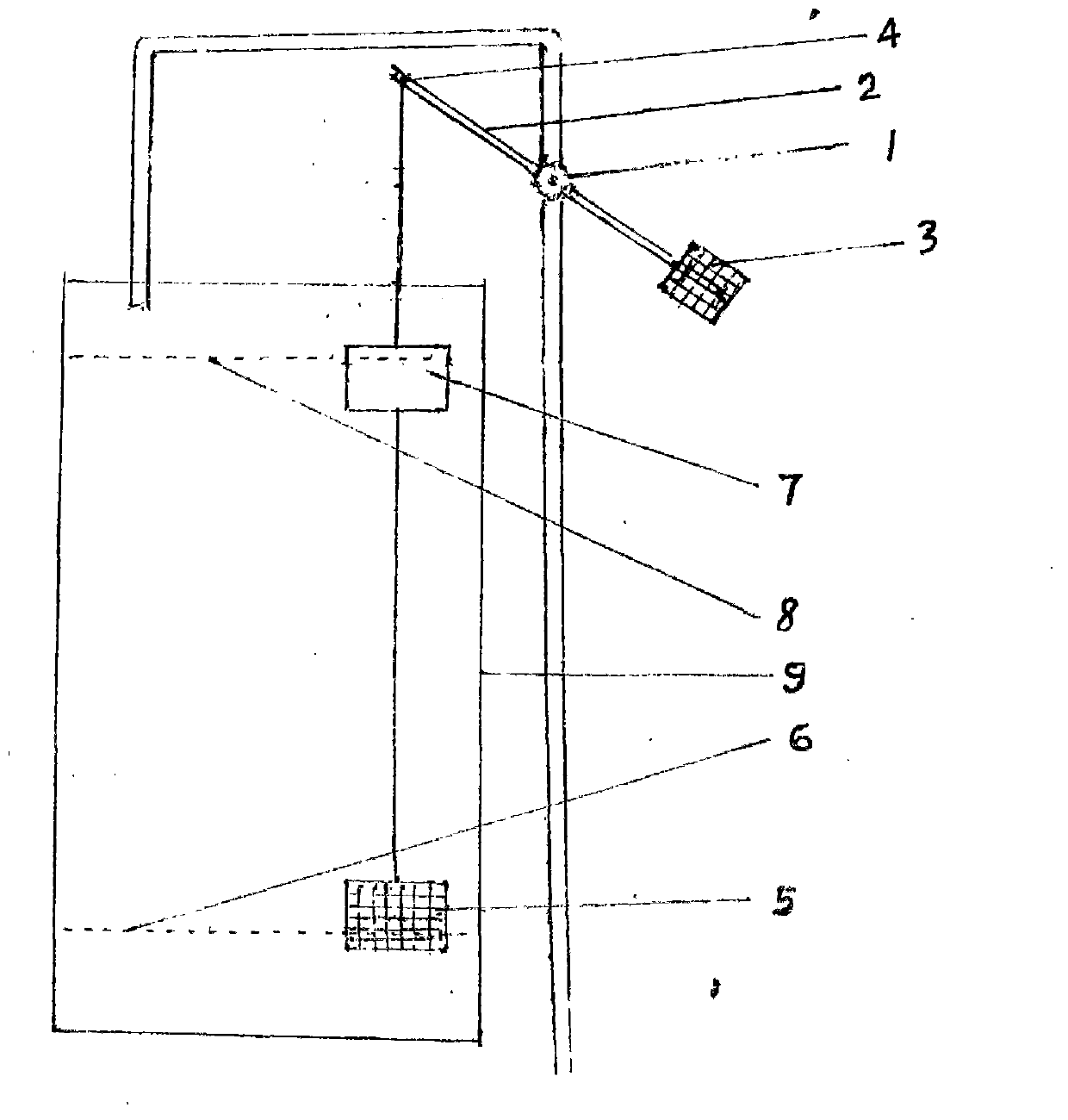

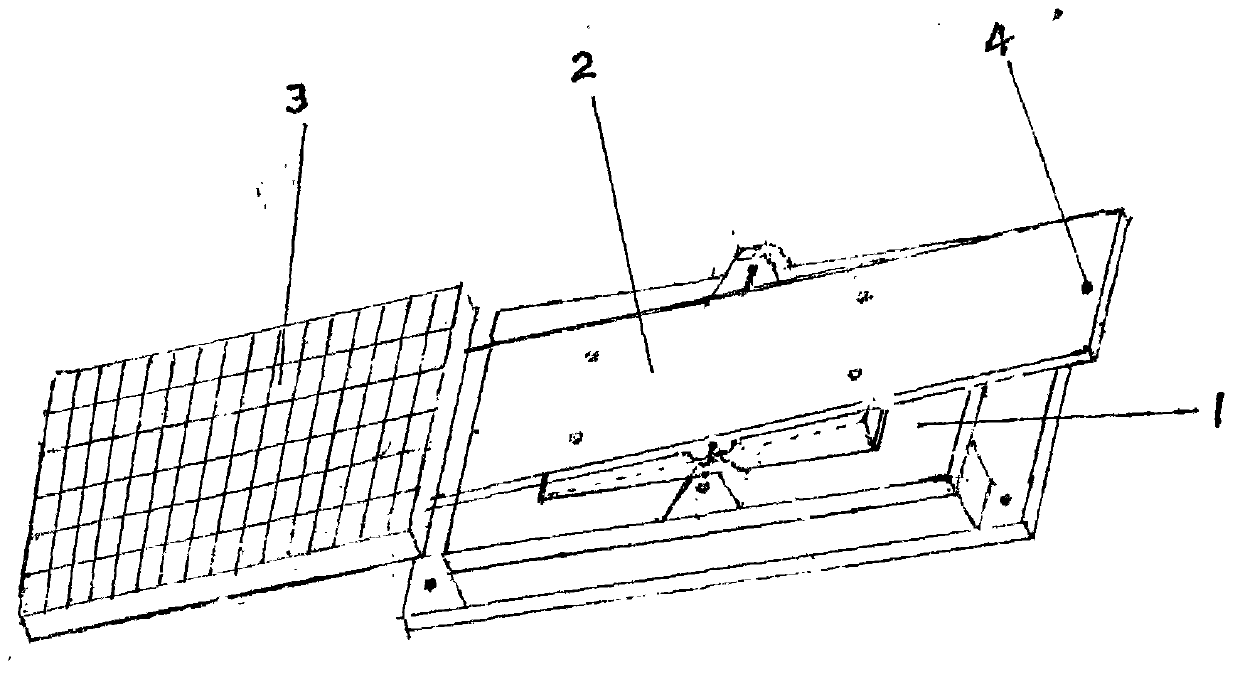

[0010] exist figure 1 , figure 2 Among them, on the manual operation surface of the existing water supply and power supply switch (1), the weight lever (2) and the pressure weight (3) (also including the weight of the lever and the spring force can be used) are directly or indirectly arranged with the same force direction, If the object to be operated is water ingress, it must be equipped with a heavy object that can be closed (3) (it can be opened when the water exits). In addition, the force that is equipped with the water of the opened end and the object to be controlled is double the force that can be closed and sometimes No variable gravity (4) is connected and self-opening, and the variable gravity ballast (5) must be larger than water with specific gravity and can keep balance with the closed pressure weight (3) in the buoyancy and is stipulated at the lower water level (6) , Float (7) is stipulated at upper water level (8), keeps the stability of switch and restrains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com