Production process of enameled rectangular wire and forming mechanism of enameled rectangular wire

A technology of enamelled flat wire and production process, which is applied in the direction of electrical components, circuits, conductors/cable insulation, etc., can solve the problems affecting the quality of enameled wires, the replacement process is cumbersome and time-consuming, and the application range is limited, etc., to achieve a wide range of use , Easy to operate, avoid the effect of wrong operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

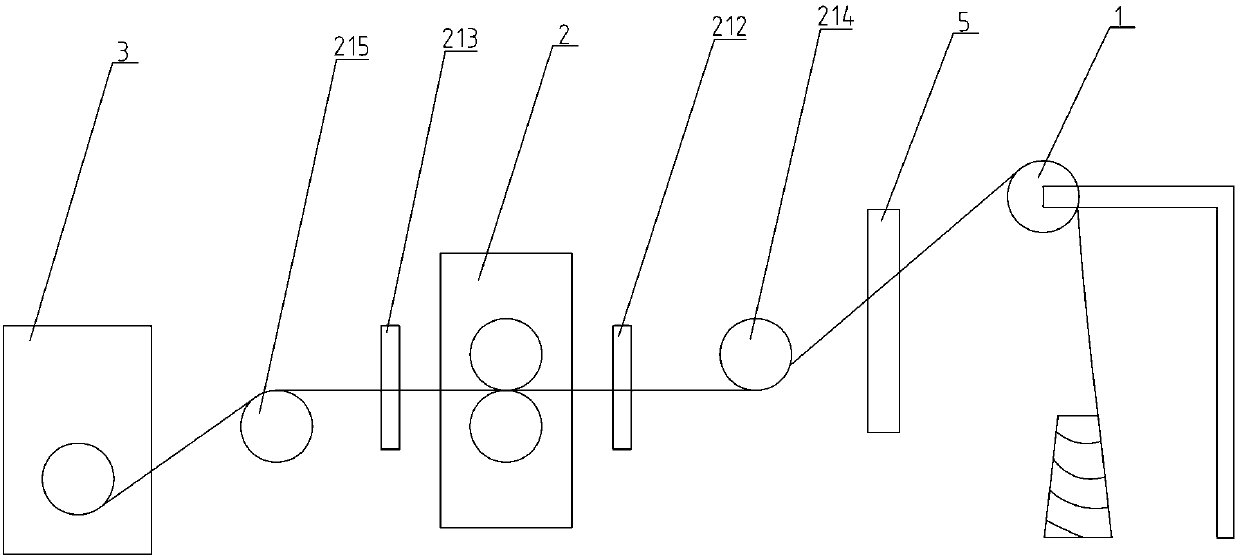

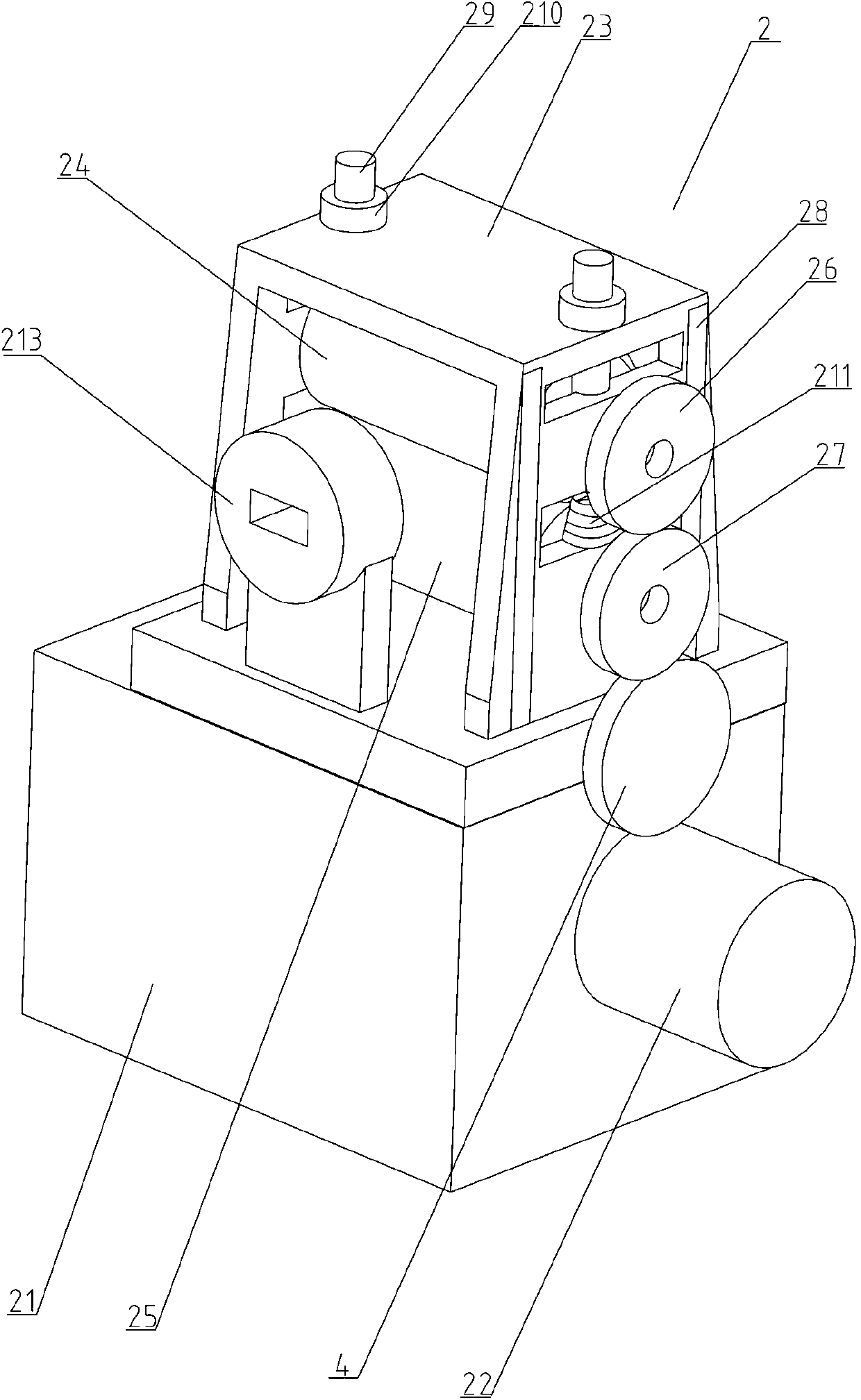

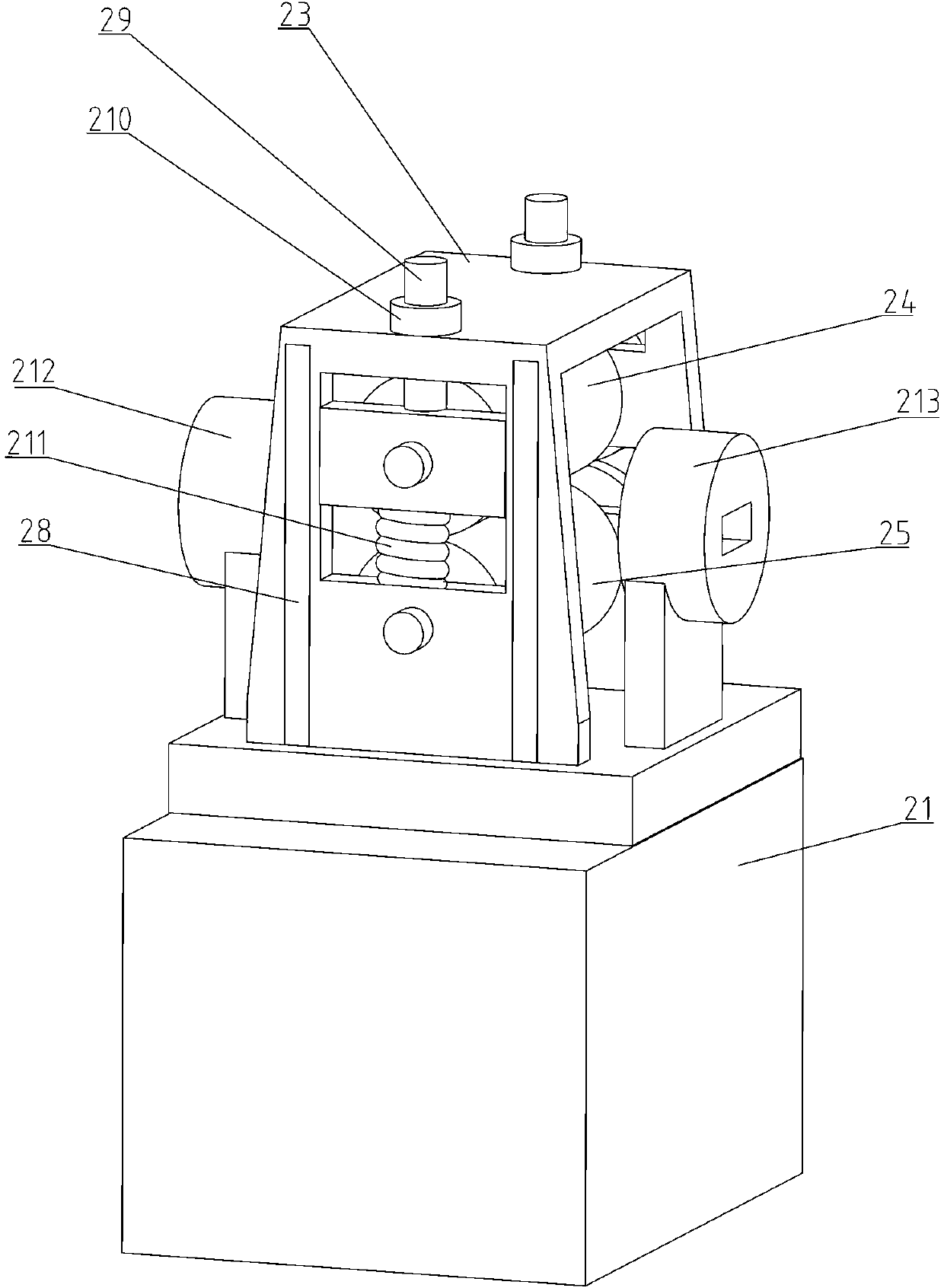

[0034] The production technique of enamelled flat wire of the present invention, it carries out according to following process steps:

[0035] 1) Stretching the metal rod: after multiple stages of stretching, the metal rod is made into a wire drawing metal wire required by the standard specification. In actual operation, a φ9.500mm aluminum rod is used to make use of the ductility of the metal , After the large drawing machine, the middle drawing machine, and the small drawing machine, the metal rod is drawn into the drawing bare wire required by the standard specification.

[0036] 2) Cleaning treatment: After being straightened, the wire drawing is smoothly sent into ultrasonic water for cleaning, and the dirt on the surface of the bare metal wire is cleaned.

[0037] 3) Heat treatment: Electrothermal annealing treatment is performed on the drawn metal wire. The ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com