Touch control module and preparation method thereof

A touch module and touch element technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problems of high production cost, poor mass production, low yield, etc. Low effect, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

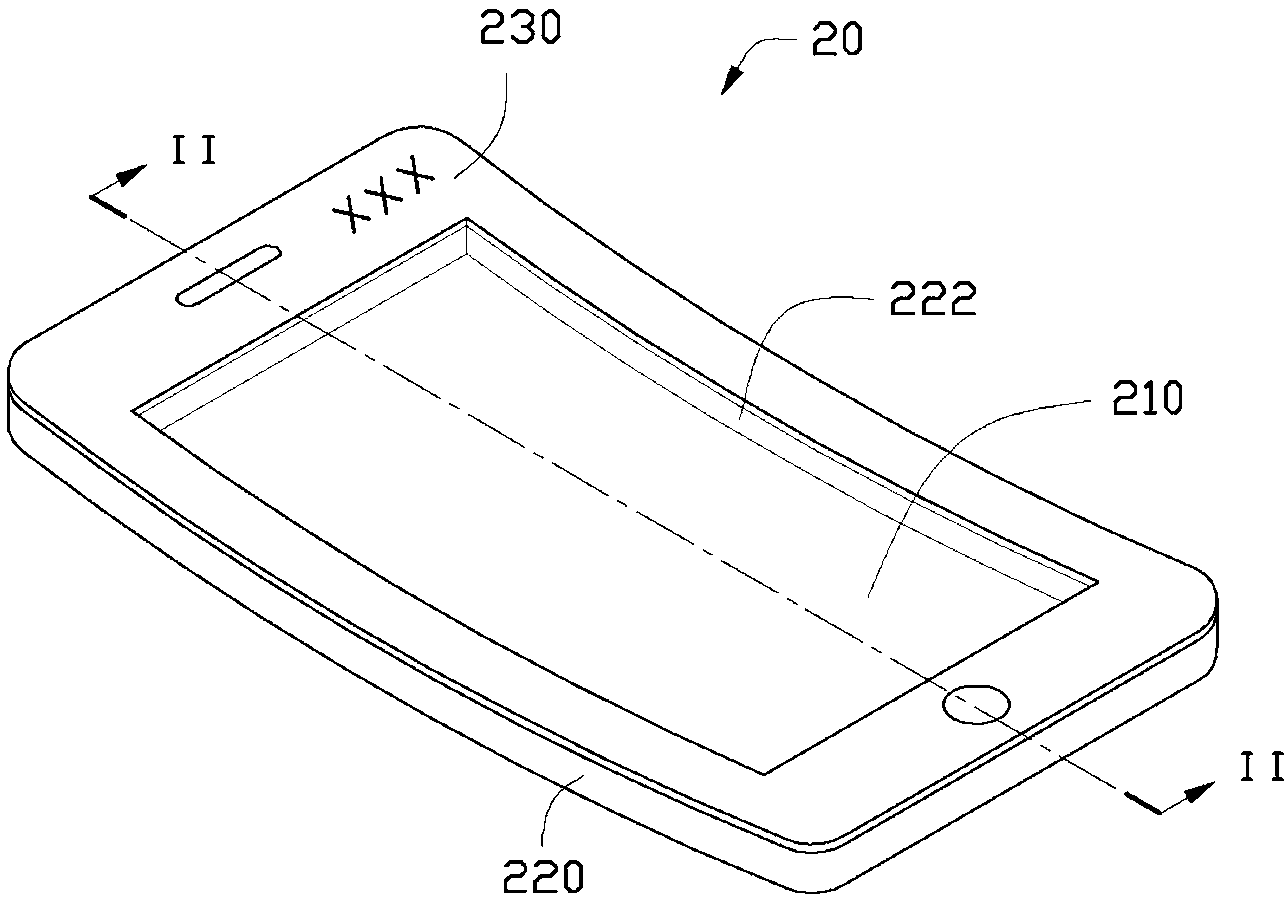

Image

Examples

preparation example Construction

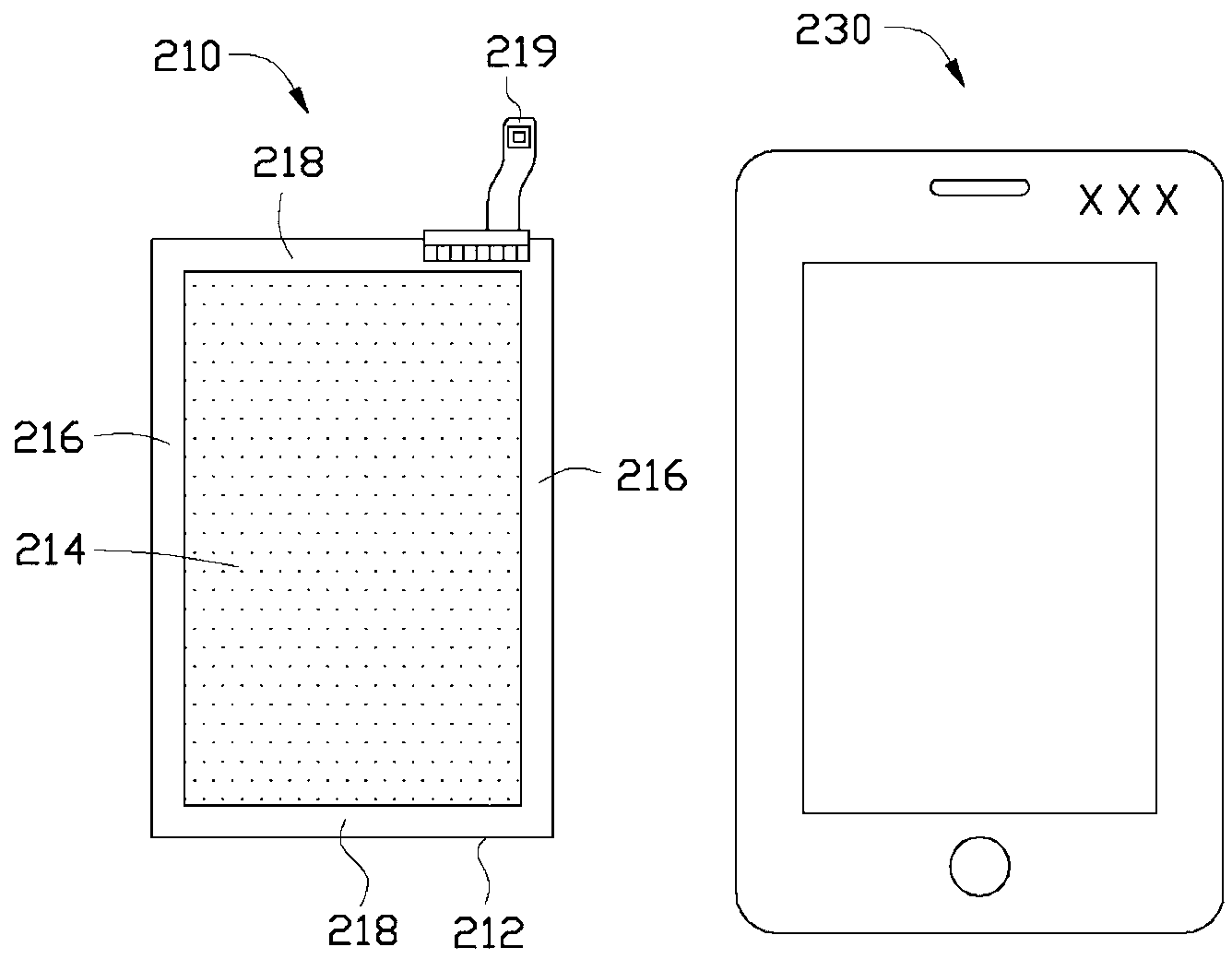

[0028] The present invention further provides a method for preparing the above-mentioned touch module. The preparation method mainly combines the in-mold decoration process and double-coated film technology to prepare the touch module. Specifically, the preparation method includes the following steps: a, providing the touch element, the decorative film and a mold, the mold including a master mold and a male mold; b, separately forming the touch element and the decorative film fixed on the female mold and the male mold; c, mold closing, injecting an injection molding material into the mold for injection molding to form the touch module; and d, demolding, taking out the touch module mod.

[0029] In step a, the female mold and the male mold in the mold are molded together to form a mold cavity, and the mold cavity is used for placing the touch element and the decorative film. The specific structure of the mold is related to the required structure of the touch module. The mold c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com