Pipeline double-thread connection structure penetrating through cartridge receiver

A connection structure, double thread technology, applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., can solve problems such as heavy workload, and achieve the effect of reducing friction, reducing wear and improving sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

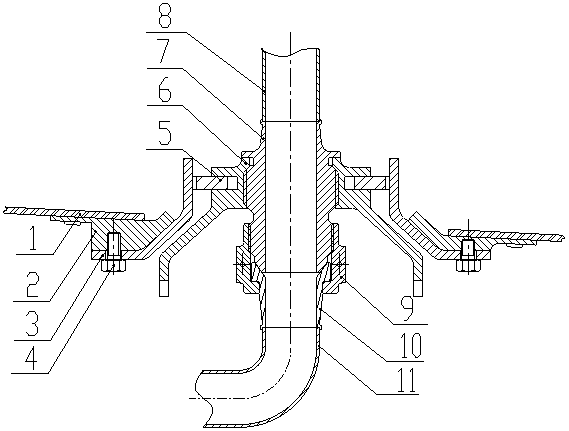

[0017] This embodiment provides a pipeline double-thread connection structure passing through the casing, which is characterized in that it includes a casing 1, a casing mounting seat 2, a lead-out pipe sleeve 3, a bolt 4, a floating ring 5, a sealing screw Sleeve 6, double-thread external cone joint 7, conduit 8, external nut 9, flat nozzle 10, conduit 11;

[0018] Among them: the outer cone joint 7 and the conduit 8 are welded together, which is the casing inner conduit assembly; the external nut 9, the flat nozzle 10, and the conduit 11 are welded together, which is the casing outer conduit assembly, and the casing mounting seat 2 is welded or riveted On the casing 1, the lead-out tube sleeve 3 is fixed on the casing mounting base 2 by four bolts 4, and the floating ring 5 is installed between the sealing screw sleeve 6 and the lead-out tube sleeve 3 to realize the opening of the casing. Sealing and installation and thermal compensation of piping through the receiver.

[0...

Embodiment 2

[0024] This embodiment provides a pipeline double-thread connection structure passing through the casing, which is characterized in that it includes a casing 1, a casing mounting seat 2, a lead-out pipe sleeve 3, a bolt 4, a floating ring 5, a sealing screw Sleeve 6, double-thread external cone joint 7, conduit 8, external nut 9, flat nozzle 10, conduit 11;

[0025] Among them: the outer cone joint 7 and the conduit 8 are welded together, which is the casing inner conduit assembly; the external nut 9, the flat nozzle 10, and the conduit 11 are welded together, which is the casing outer conduit assembly, and the casing mounting seat 2 is welded or riveted On the casing 1, the lead-out tube sleeve 3 is fixed on the casing mounting base 2 by six bolts 4, and the floating ring 5 is installed between the sealing screw sleeve 6 and the lead-out tube sleeve 3 to realize the opening of the casing. Sealing and installation and thermal compensation of piping through the receiver.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com