Drives for hinges and pivoting adjustment arms

A technology that rotates around an axis and drives a device. It is applied to hinges with pins, switches with brakes, and door/window accessories. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

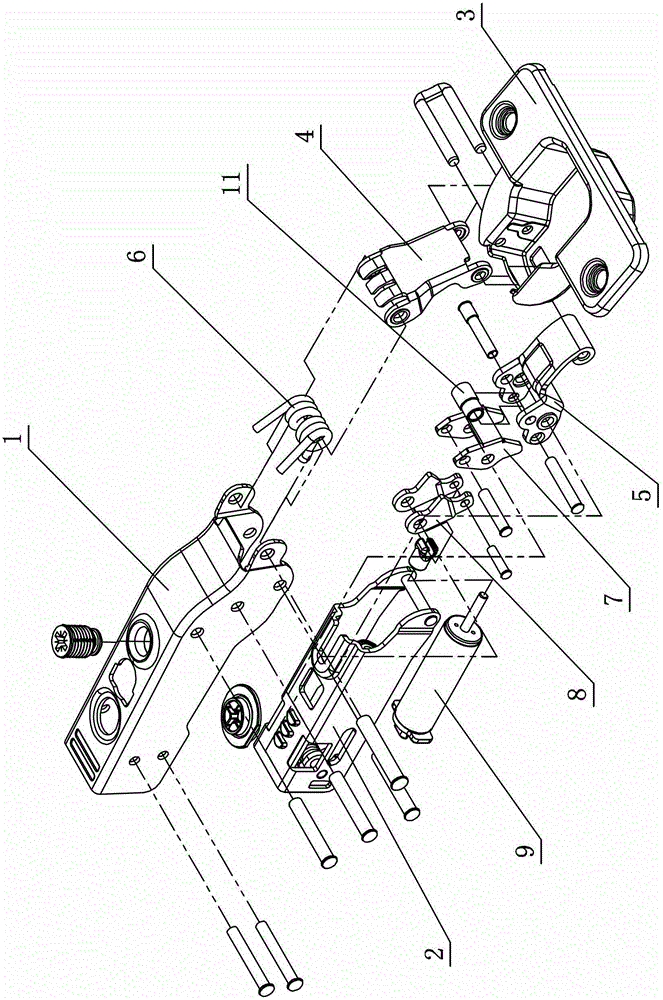

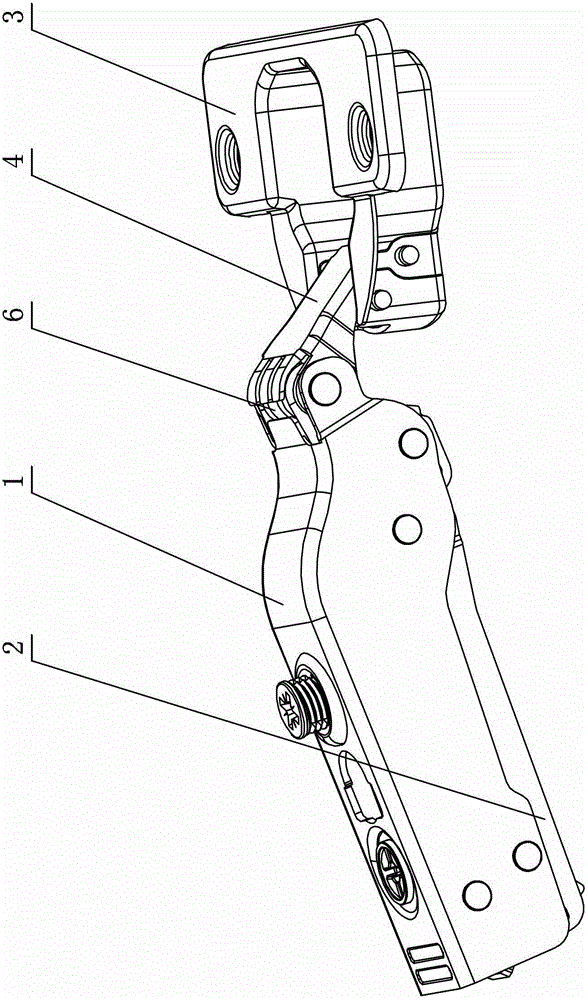

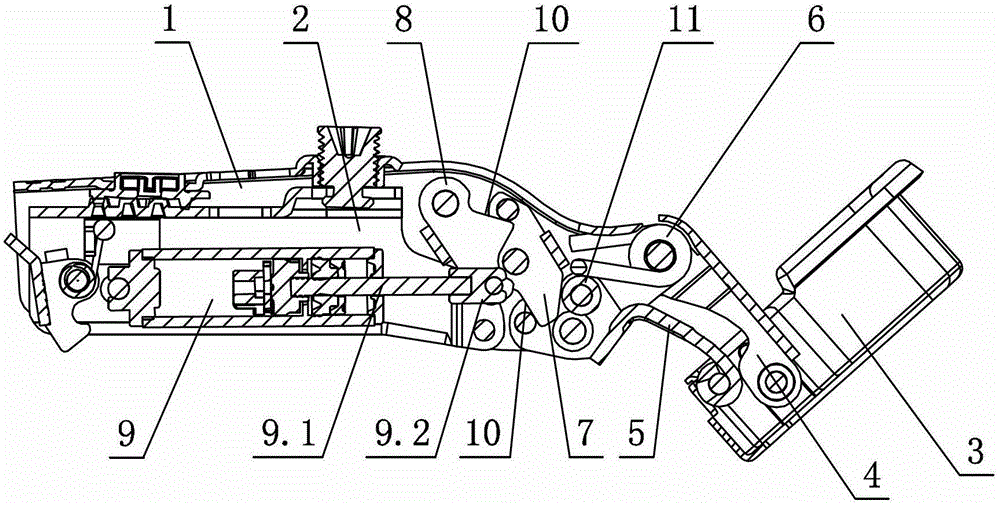

Method used

Image

Examples

no. 2 example

[0033] see Figure 5 The difference from the first embodiment is that the hinge closing working surfaces 10 provided on the pendulum block 8 and the middle pendulum member 7 are all U-groove-shaped planes. Others are not described with the first embodiment.

no. 3 example

[0035] see Image 6 The difference from the first embodiment is that the hinge closing working surface 10 provided on the pendulum block 8 is an open plane, and the hinge closing working surface 10 provided on the middle swinging member 7 is a U-groove-shaped plane. Others are not described with the first embodiment.

no. 4 example

[0037] see Figure 7 The difference from the first embodiment is that the hinge closing working surface 10 provided on the pendulum block 8 is a U-groove-shaped plane, and the hinge closing working surface 10 provided on the middle swinging member 7 is an open plane. Others are not described with the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com