Improved structure of hot runner mold

An improved structure and hot runner technology, which is applied in the field of injection molds, can solve the problems of complex mold structure and high manufacturing cost of hot runner molds, and achieve the effects of improving mold quality, preventing excessive heat loss, and avoiding wire drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

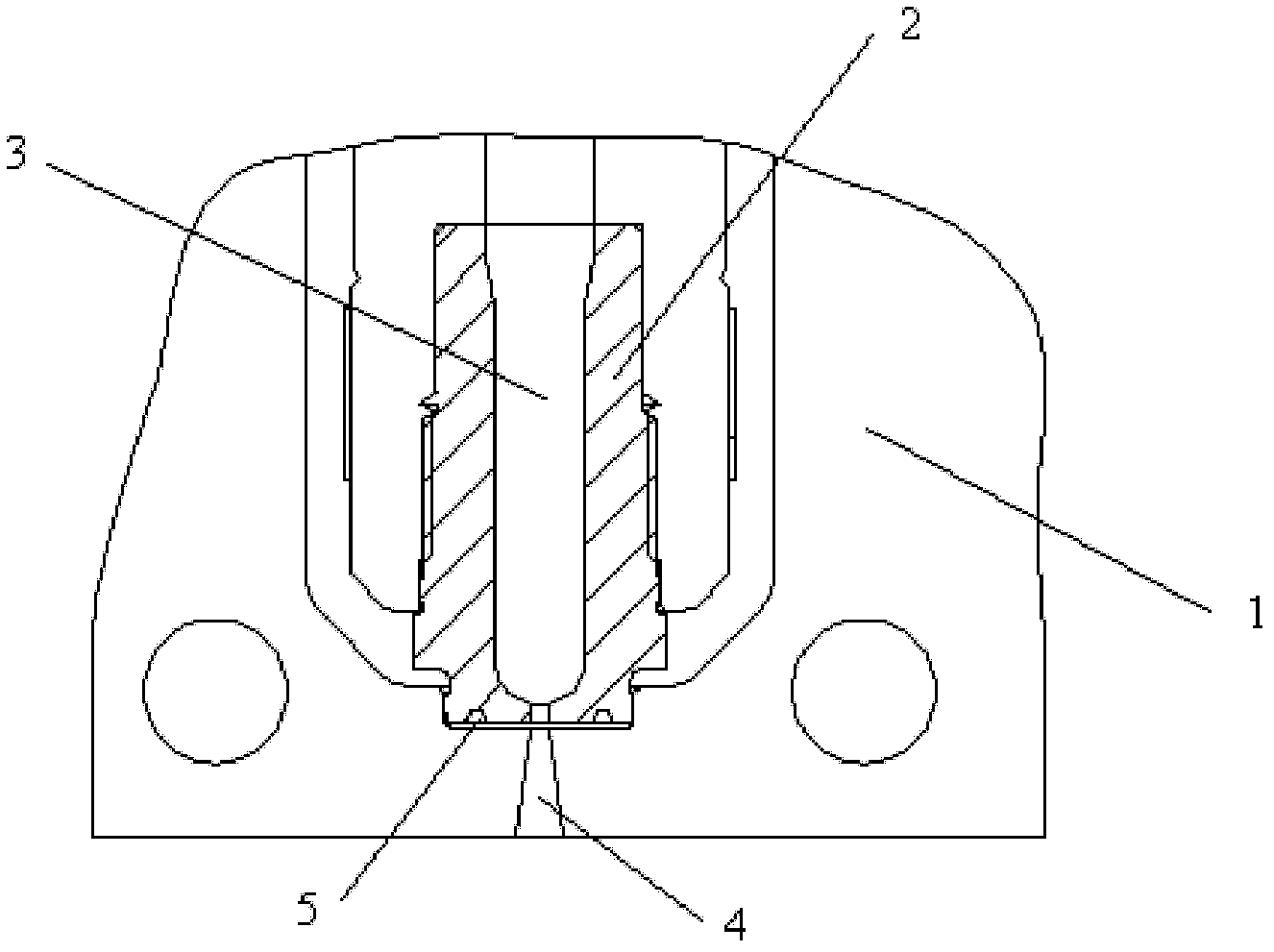

[0008] The embodiment of the improved structure of the hot runner mold of the present invention will be described in detail below with reference to the accompanying drawings.

[0009] The improved structure of a hot runner mold according to the present invention includes a hot template 1, a bushing 2 and a hot runner 3 positioned on the bushing and communicating with the cavity of the mould, the hot template and the A gap is formed between the bushes, and the bush is integrally formed with the main channel bush and the nozzle bush, so that the diameter of the hot runner can be enlarged and the plastic flow is facilitated; and the bush faces one end of the cavity There are several round holes 5, which can prevent excessive heat loss at the nozzle of the hot runner; a cold runner 4 is provided between the nozzle of the hot runner and the cavity, and the cold runner is positioned On the thermal template 1 of the hot runner.

[0010] In this embodiment, the circular holes are pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com