Furniture composite board

A technology for composite boards and furniture, which is applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers, and can solve the problems of short service life, moisture resistance, poor mildew resistance, and composite boards being easily eaten by mice. The effect of increasing strength and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

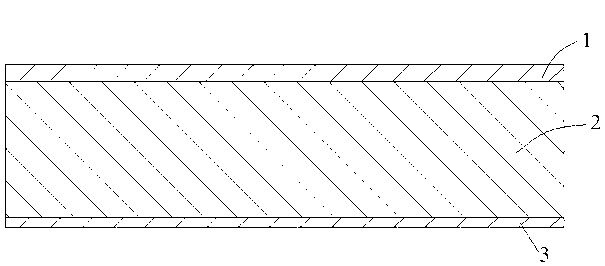

[0010] The furniture composite panel is composed of a stainless steel panel 1 and a wooden core panel 2. The upper surface of the core panel 2 is bonded to the lower surface of the stainless steel panel 1 through an adhesive, and the lower surface of the core panel 2 is painted with a paint layer 3. The stainless steel panel 1 The thickness is 0.2mm, the thickness of the wooden core board 2 is 12mm, and the thickness of the paint layer 3 is 0.1mm.

[0011] The stainless steel panel 1 is bonded on the upper surface of the core board 2, which can not only increase the strength of the composite board, but also achieve the effect of preventing rats from biting, and increase the service life of the composite board; paint the paint layer 3 on the lower surface of the core board 2 , Use the denseness of the paint to protect the core board, and play the role of moisture-proof and mildew-proof.

Embodiment 2

[0013] The furniture composite panel is composed of a stainless steel panel 1 and a wooden core panel 2. The upper surface of the core panel 2 is bonded to the lower surface of the stainless steel panel 1 through an adhesive, and the lower surface of the core panel 2 is painted with a paint layer 3. The stainless steel panel 1 The thickness is 0.1mm, the thickness of the wooden core board 2 is 10mm, and the paint layer thickness is 0.2mm.

Embodiment 3

[0015] The furniture composite panel is composed of a stainless steel panel 1 and a wooden core panel 2. The upper surface of the core panel 2 is bonded to the lower surface of the stainless steel panel 1 through an adhesive, and the lower surface of the core panel 2 is painted with a paint layer 3. The stainless steel panel 1 The thickness is 0.5mm, the thickness of the wooden core board 2 is 15mm, and the thickness of the paint layer 3 is 0.05mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com