A method for preparing a radial permanent magnet ring and its manufacturing device

A technology for preparing a device and a permanent magnet ring, which is applied in the manufacture of inductors/transformers/magnets, permanent magnets, electrical components, etc., can solve the problem of poor uniformity of orientation degree of radial permanent magnet rings, reduction of orientation magnetic field strength, uneven orientation degree, etc. problems, to achieve the effect of improving the uniformity of radial orientation, improving uniformity, and improving the yield of molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

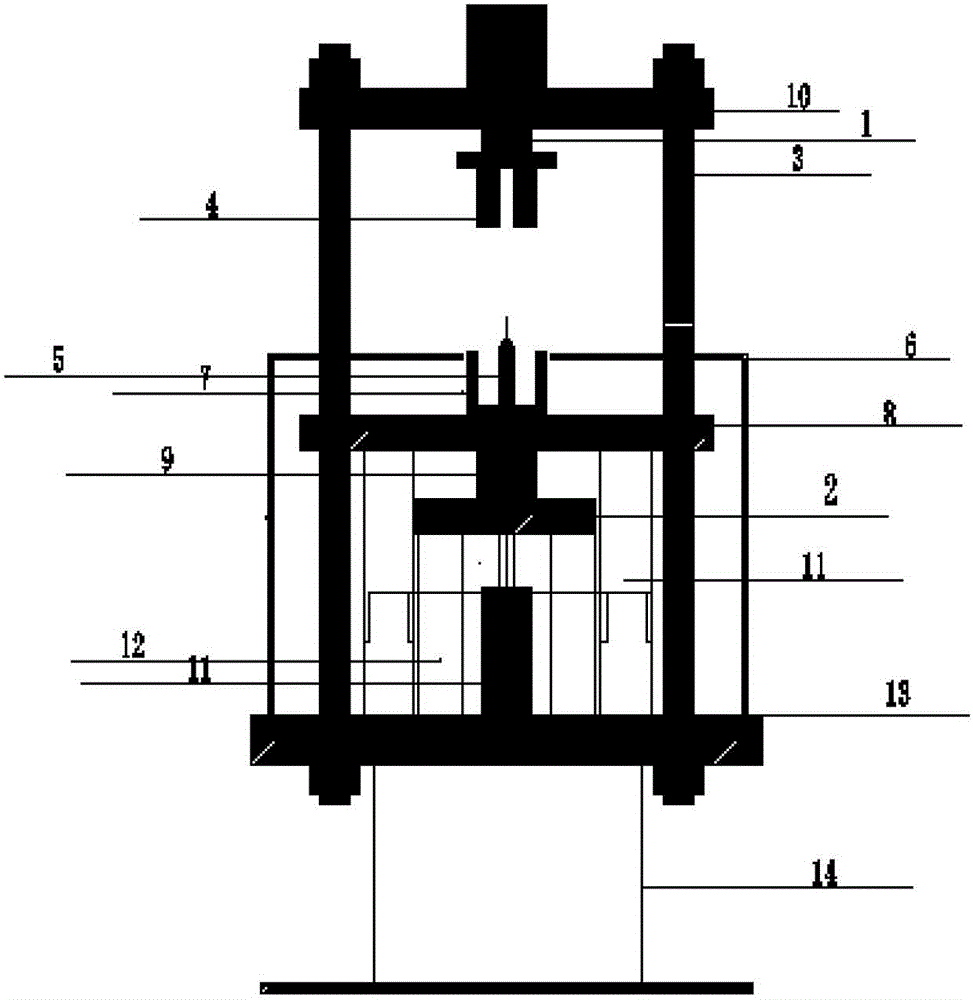

[0018] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0019] Such as figure 1 The radial permanent magnetic ring preparation device shown: the outer mold cavity is a detachable circular cylinder, which is fixed on the movable plate, and the outer mold cavity is fixed on the movable plate made of non-magnetic material, which can be moved up and down by the movable plate And drive the movement of the outer mold cavity; the upper punch of the press is a detachable circular ring, the lower punch is fixed on the non-magnetic fixed plate, and its position remains fixed during the pressing process; the center mandrel is held by the magnetic It is made of high-quality material and act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com