A vertical bending machine

A technology of bending machine and bending mechanism, which is applied in the field of bending machines, can solve the problems of long time consumption and affecting bending efficiency, etc., and achieve the effects of reducing friction, improving workpiece quality, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

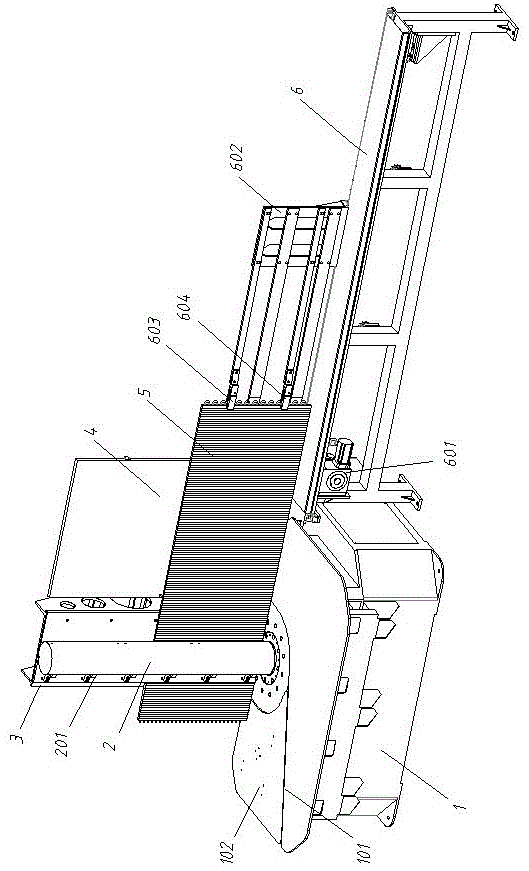

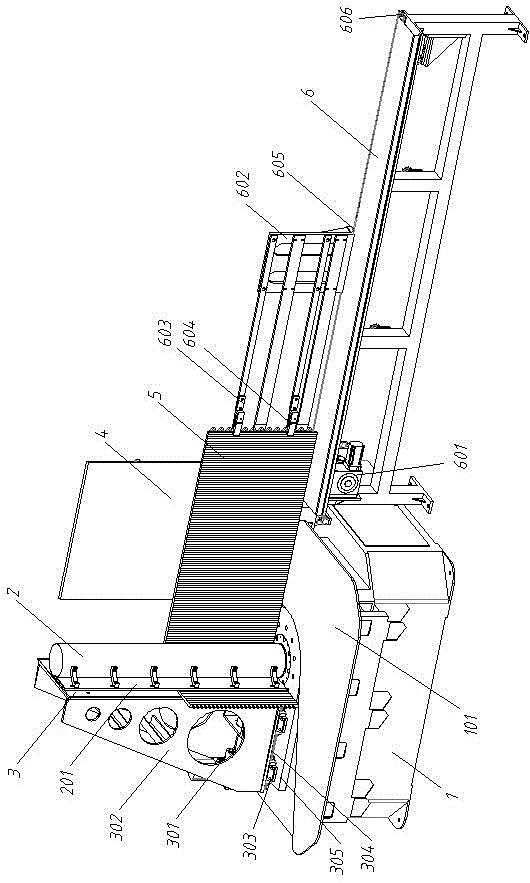

[0034] Such as figure 1 As shown, a vertical bending machine includes a fuselage 1, a bending mechanism, a follower plate 4, a feeding device 6, and a working table mounted on the fuselage.

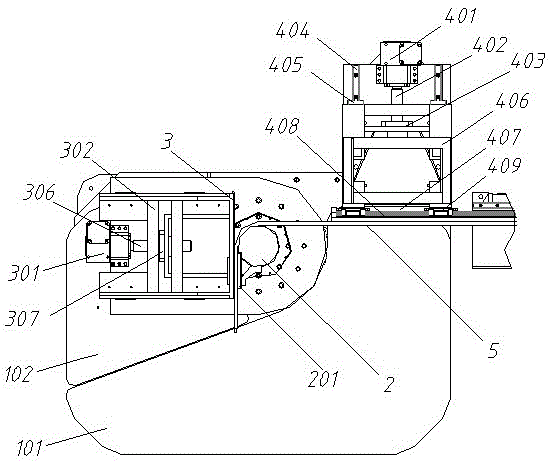

[0035] Image 6 It is the bending mechanism of the vertical bending machine in this embodiment, and its bending die rotation mechanism is the first servo motor 203 with the first reducer, and the end of the first reducer output shaft 207 of the first servo motor 203 is installed with the bending die 2. The output shaft 207 is supported by bearings in the bending die sleeve 205, and the first servo motor 203 is fixed on the bending die sleeve 205 through the connecting flange 206, so the first servo motor 203 can drive the output shaft 207 to rotate independently, thereby Drive the bending die 2 fixed on the output shaft 207 to rotate, but the bending di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com