Methodology of forming optical lens for semiconductor light emitting device

A technology of optical lens and light-emitting device, which is applied in the direction of semiconductor devices, electric solid-state devices, electrical components, etc., and can solve the problems of light output loss, yield loss, packaging material waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the detailed description that follows, numerous specific details are set forth in order to provide a thorough understanding of the invention. However, it will be understood by those skilled in the art that the present invention may be practiced without these specific details. In other instances, well-known methods, procedures and / or components have not been described in detail so as not to obscure the present invention.

[0040] The present invention will be more clearly understood by the following description of the examples, given by way of example only by reference to the accompanying drawings, which are not drawn to scale.

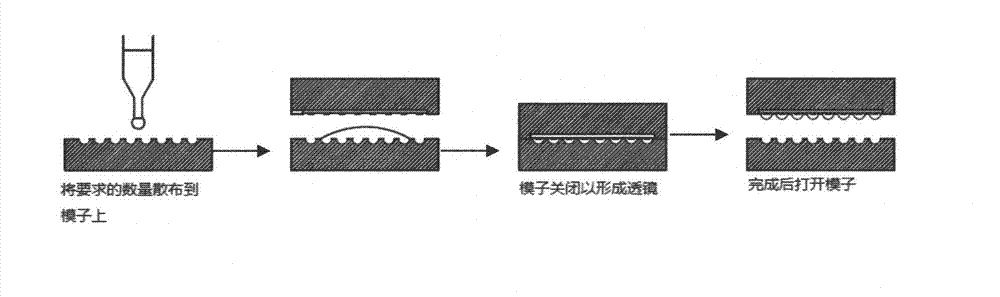

[0041] refer to Figure 1-A , a schematic diagram showing a conventional method of forming an optical lens for a semiconductor light emitting device by using an injection molding process. A quantity of encapsulant material is spread over a mold provided with depressions or cavities corresponding to the desired lens shape. By applying pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com