Fully-automatic calibration method for hand-eye robot based on exponential product model

A calibration method and robot technology, which can be applied to instruments, measuring instruments, image data processing, etc., can solve the problems of complex and complicated calibration process, and achieve the effect of simple, high precision and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

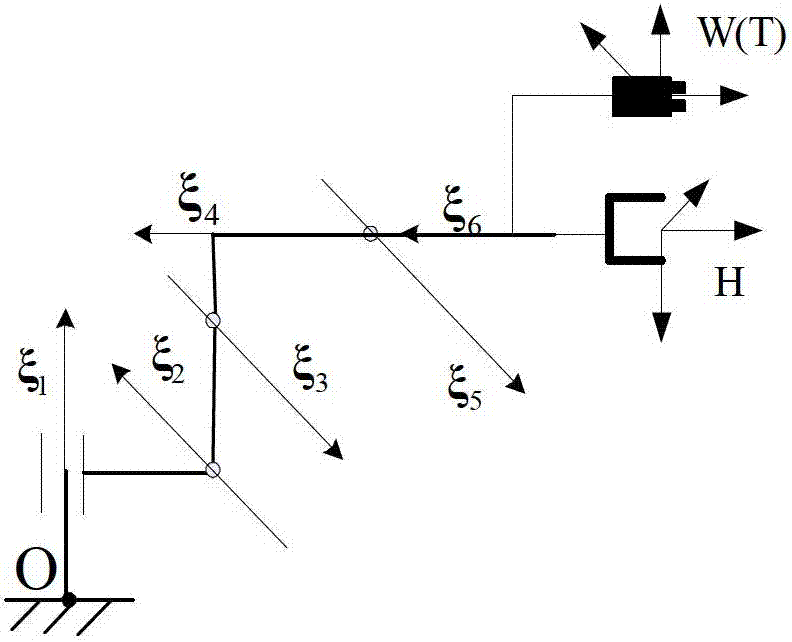

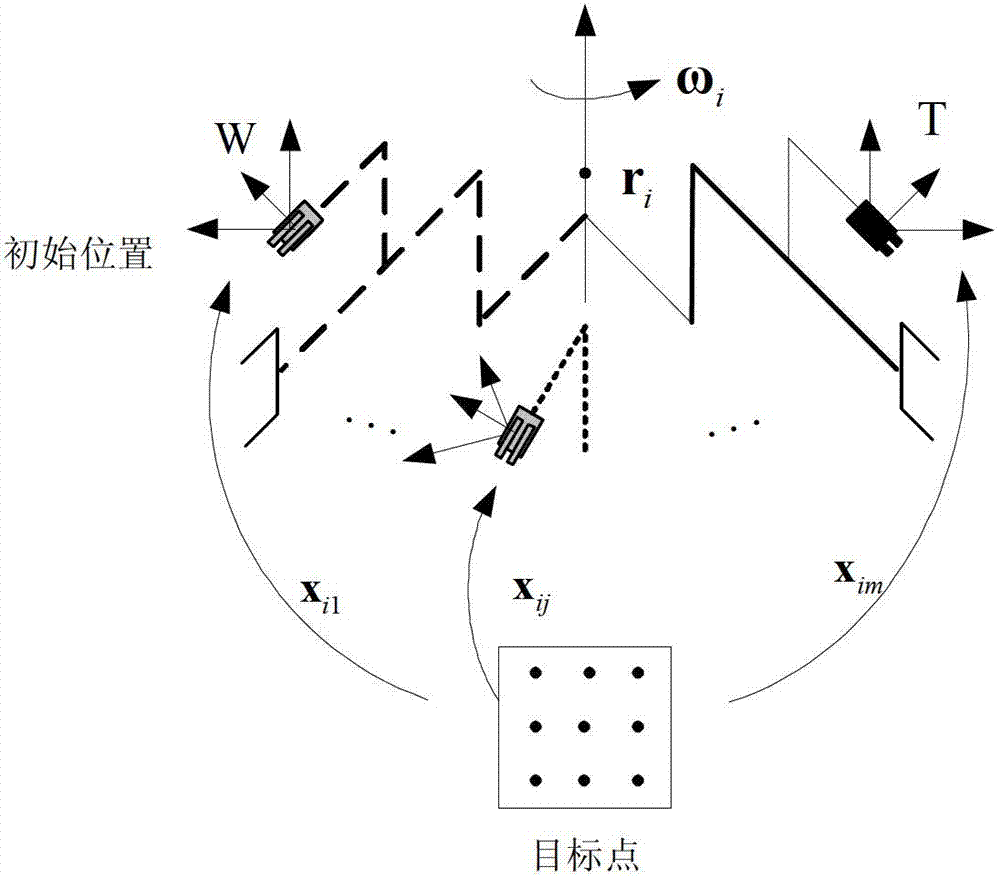

[0026] figure 1 Shown is a diagram of the robot kinematics model. At the initial position, both the world coordinate system W and the tool coordinate system T are established on the end camera of the robot. The world coordinate system is fixed at the initial position, and the tool coordinates move with the movement of the robot. It is assumed that the robot has n series of rotary joints , then the exponential product motion model of the robot is:

[0027] g wt ( θ ) = e θ 1 ξ ^ 1 e θ 2 ξ ^ 2 . . . e ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com