Lever type pneumatic cradle of roving machine

A lever type, roving frame technology, used in spinning machines, textiles and papermaking, drafting equipment, etc., can solve problems such as difficulty in maintaining the same cradle, low spinning quality, low work efficiency, etc., to achieve long-term constant pressure, Suitable for a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

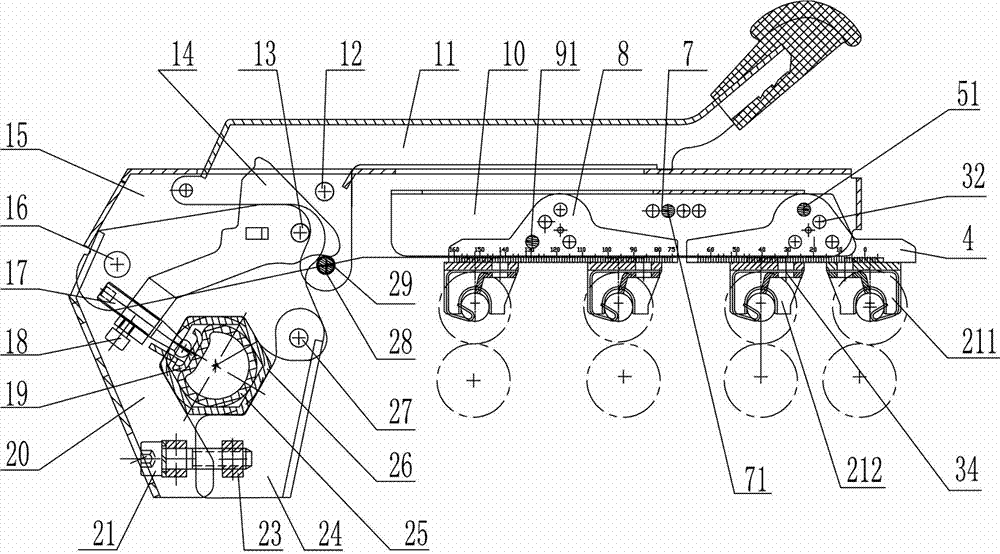

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

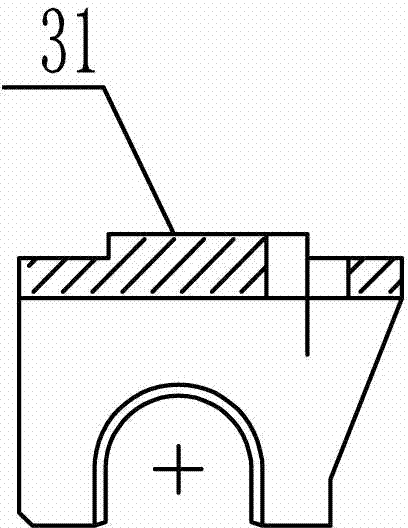

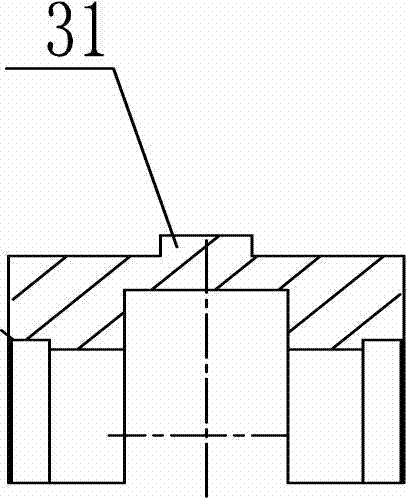

[0018] like Figure 1 to Figure 9 The lever-type pneumatic cradle of the roving frame shown in , includes the cradle shell 15, the handle 11 is hinged with the cradle shell 15 through the handle pin 12, and the cradle shell 15 is gripped with the cradle by the shell pin 16. The seats are hinged with each other, the pressure pin sleeve 28 is arranged on the lower end of the handle 11 through the pressure pin 29, the pressure transmission crank 14 is hinged with the upper card support 20 through the crank pin 13, and the bottom of the front end of the pressure transmission crank 14 is provided with a pressure groove. When closed, the pressure pin sleeve 28 is clamped in the pressure groove so as to press the handle 11 tightly on the cradle shell 15, and the pressure crank 14 transmits the pressure to the handle 11 through the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com