Part segmentation photograph processing method and system

A technology of partial segmentation and processing method, which is applied in image data processing, CCTV systems, components of TV systems, etc., to save time and reduce the number of comparisons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

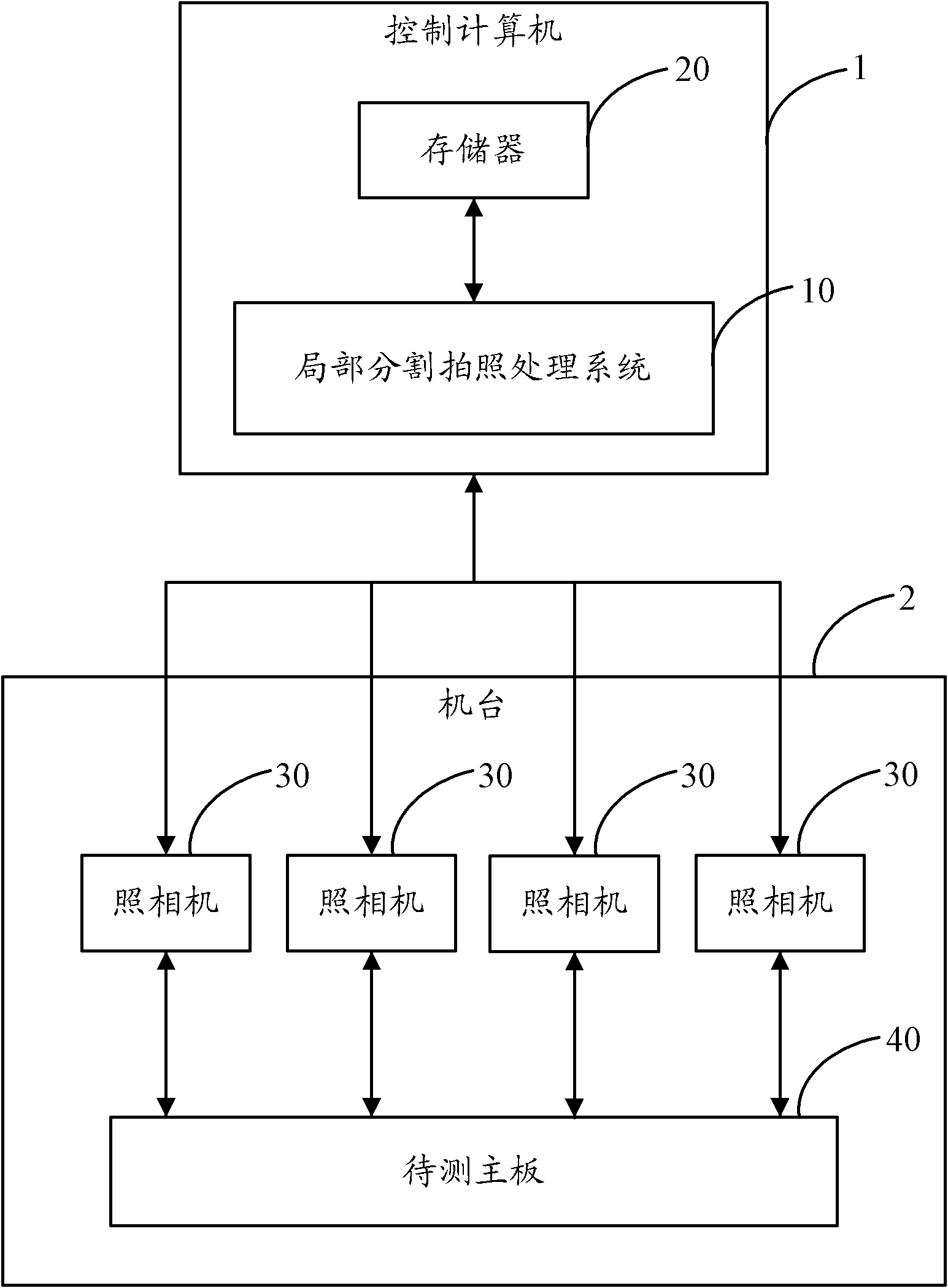

[0015] refer to figure 1 As shown, it is an application environment diagram of a preferred embodiment of the local segmentation and photographing processing system of the present invention. The partial segmentation photographing processing system 10 runs in the control computer 1 , and the control computer 1 also includes a memory 20 . The control computer 1 is connected to the machine platform 2, and the machine platform 2 includes a plurality of cameras 30 (four are shown in the figure as a representative) and a main board 40 to be tested. The camera 30 is connected to the control computer 1 via a USB cable.

[0016] The control computer 1 is used to control the camera 30 on the machine 2 to take pictures of the motherboard 40 to be tested, receive the taken pictures through the USB cable, process the pictures, and then compare them with the standard pictures.

[0017] The memory 20 is used for storing photos received from the camera 30 and standard photos for comparison w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com