A kind of silicon-carbon composite material and preparation method thereof, lithium-ion battery containing the material

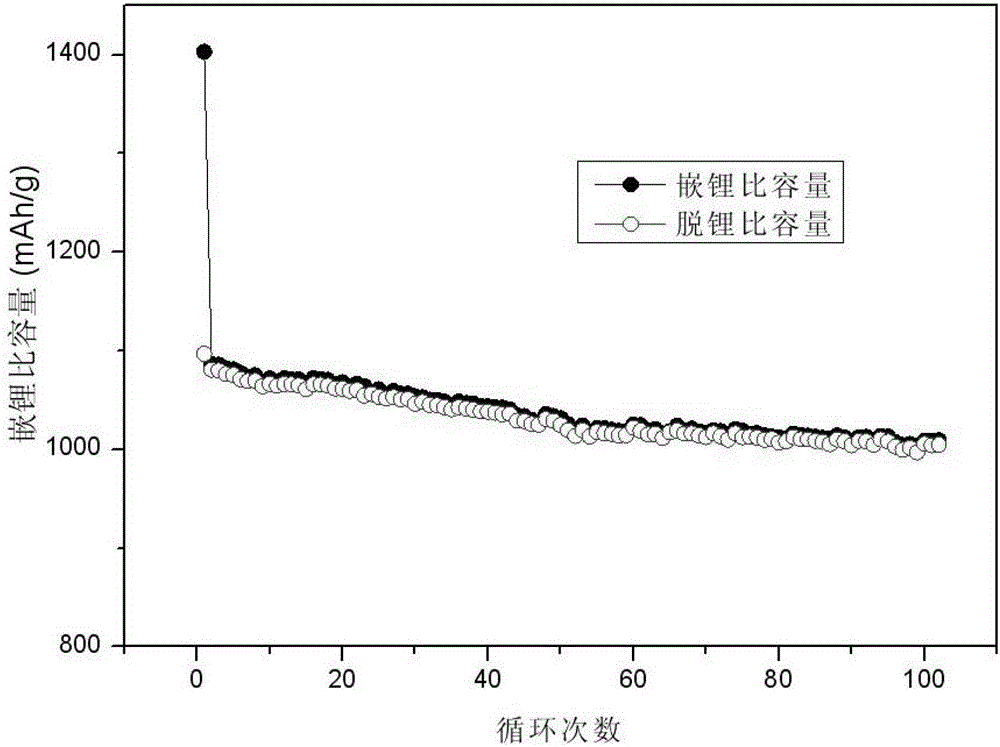

A technology of silicon-carbon composite materials and composite materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of time-consuming and labor-intensive, difficult large-scale production, etc., achieve high cycle stability, increase stability and conductivity, The effect of alleviating chalking and shedding phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

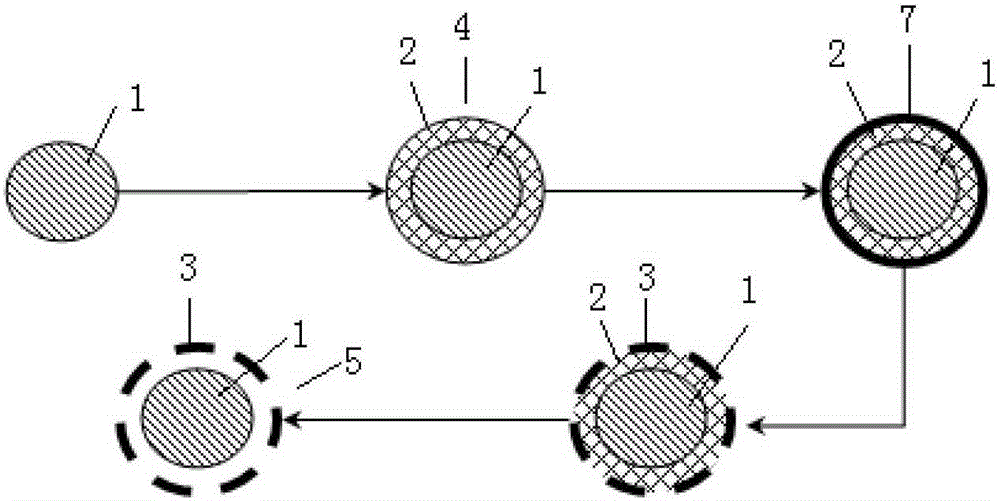

[0035] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0036] (1) Pre-oxidation

[0037] Weighed 3.0 grams of spherical nano-silicon powder with a particle size of 80 nm, burned it to 400° C. in air for 4 hours, and obtained 4.2 grams of composite material 4 of silicon dioxide coated with silicon in the form of powder. It is measured that the silicon dioxide-coated silicon composite material 4 has a silicon content of 71% and an oxygen content of 29%. Converting the oxygen content therein into the amount of silicon dioxide, it can be known that the silicon dioxide content in the silicon dioxide-coated composite material is 54%.

[0038] (2) Carbon coating

[0039]Weigh 4 grams of the above silicon dioxide-coated silicon composite material 4, add 1 gram of starch and 10 grams of water to it, and ultrasonically disperse for 30 minutes. Then transfer the mixture to a polytetrafluoroethylene reactor, seal th...

Embodiment 2

[0051] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0052] (1) Pre-oxidation

[0053] Weigh 3.0 grams of spherical nano-silicon powder with a particle size of 100 nm, burn it to 450° C. in air for 2 hours, and obtain 4.3 grams of a composite material of silicon dioxide coated with silicon in the form of powder. It is measured that in the silicon dioxide-coated silicon composite material, the silicon content is 67%, and the oxygen content is 32%. Converting the oxygen content therein into the amount of silicon dioxide, it can be seen that the silicon dioxide content in the silicon dioxide-coated silicon composite material is 60%.

[0054] (2) Carbon coating

[0055] Weigh 4 grams of the above silica-coated silicon composite material, add 2 grams of fructose and 20 grams of water to it, and ultrasonically disperse for 5 minutes. Then transfer the mixture to a polytetrafluoroethylene reactor, seal the po...

Embodiment 3

[0061] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0062] (1) Pre-oxidation

[0063] Weigh 3.0 g of spherical nano-silicon powder with a particle size of 500 nm, burn it to 600° C. in air for 1 hour, and obtain 4.7 g of a composite material of silicon dioxide coated with silicon in the form of powder. It is measured that in the silicon dioxide-coated silicon composite material, the silicon content is 64%, and the oxygen content is 36%. Converting the oxygen content therein into the amount of silicon dioxide, it can be seen that the silicon dioxide content in the silicon dioxide-coated composite material is 68%.

[0064] (2) Carbon coating

[0065] Weigh 4 g of the above silica-coated silicon composite material, add 4 g of a mixture of sucrose and lactose (wherein the molar ratio of sucrose to lactose is 1:1) and 20 g of water, and ultrasonically disperse for 100 minutes. Then transfer the mixture to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com