Device and method for kinetic study of drilling fluid and natural gas hydrate

A drilling fluid and natural gas technology, which is applied in the field of device systems for natural gas hydrate dynamics research, can solve problems such as stuck pipe, influence, measurement methods and methods that cannot meet drilling fluid research, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

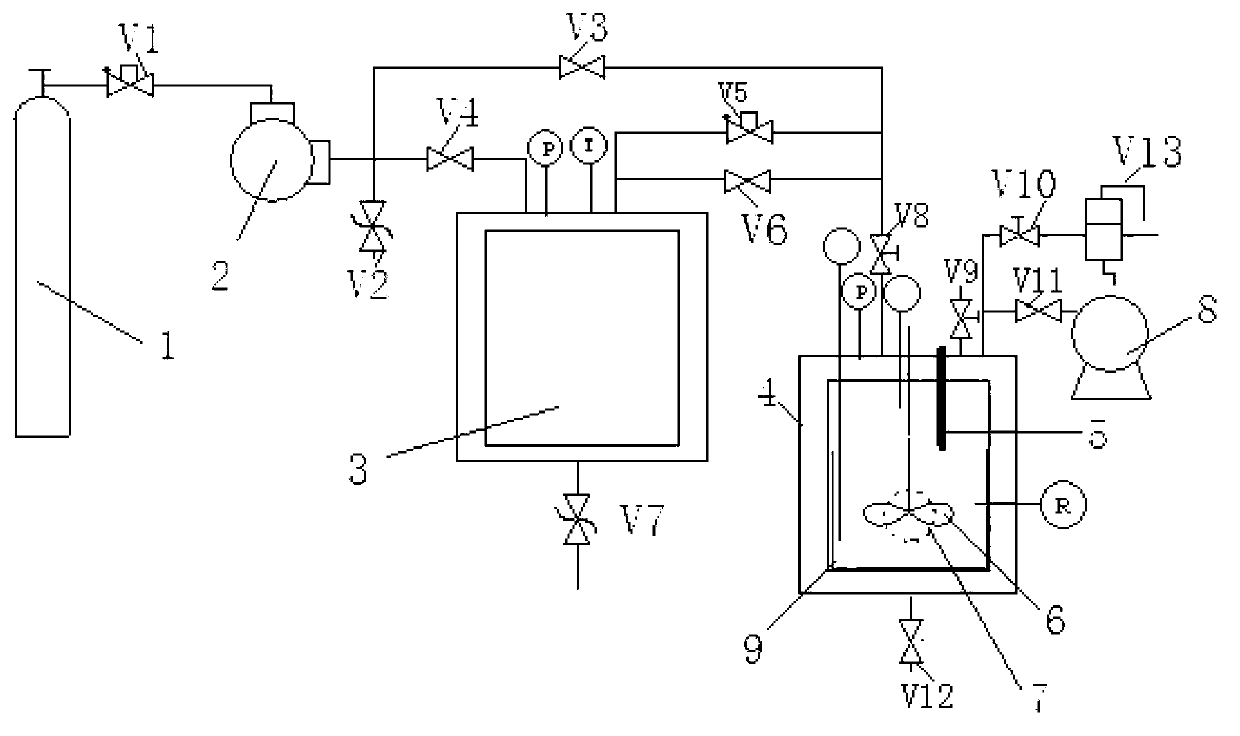

[0031] Such as figure 1 As shown, a device for studying the dynamics of natural gas hydrate in drilling fluids, including a gas source 1, a booster pump 2, a buffer tank 3, a reactor 4, and a vacuum pump 8 connected in sequence, and the gas source 1 and booster pump 2 A pressure regulating valve V1 is set between them, a valve V3 is set between the booster pump 2 and the buffer tank 3, and there are two branch connections between the buffer tank 3 and the reactor 4, and the pressure regulating valve V5 and the valve V6 are respectively set on the branch roads. After the two branches are handed over, they are connected to the reactor 4 through the valve V8, and the output of the reactor 4 is divided into two branches, one of which is connected to the vacuum pump 8 through the valve V11, and the other branch is respectively equipped with a valve V10 and Back pressure valve V13; a temperature sensor and a pressure sensor are respectively provided on the buffer tank 3 and the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com