Speed changing box capable of automatically adjusting gear meshing clearance

A technology of automatic adjustment and transmission, applied in the direction of belt/chain/gear, transmission parts, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

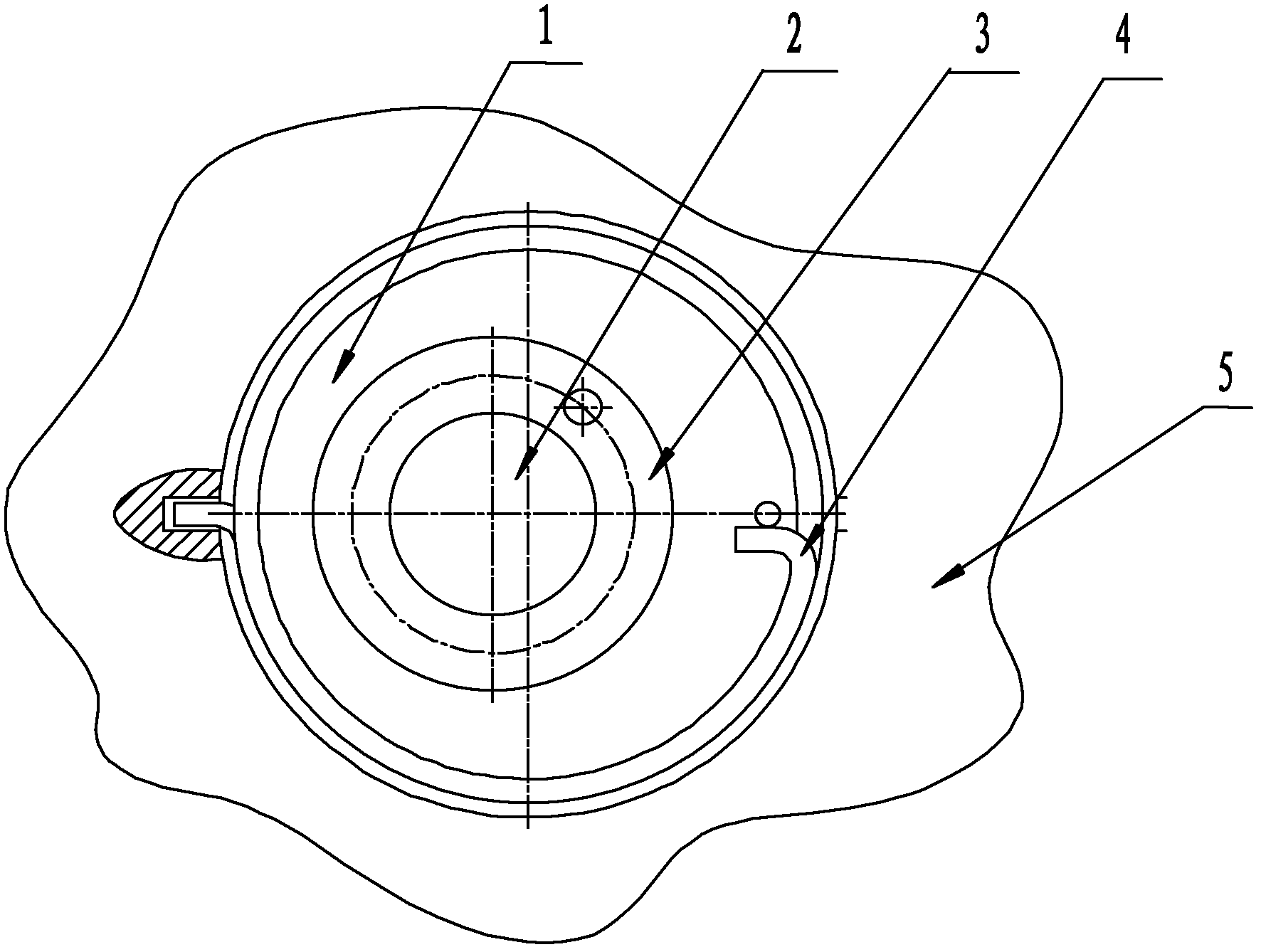

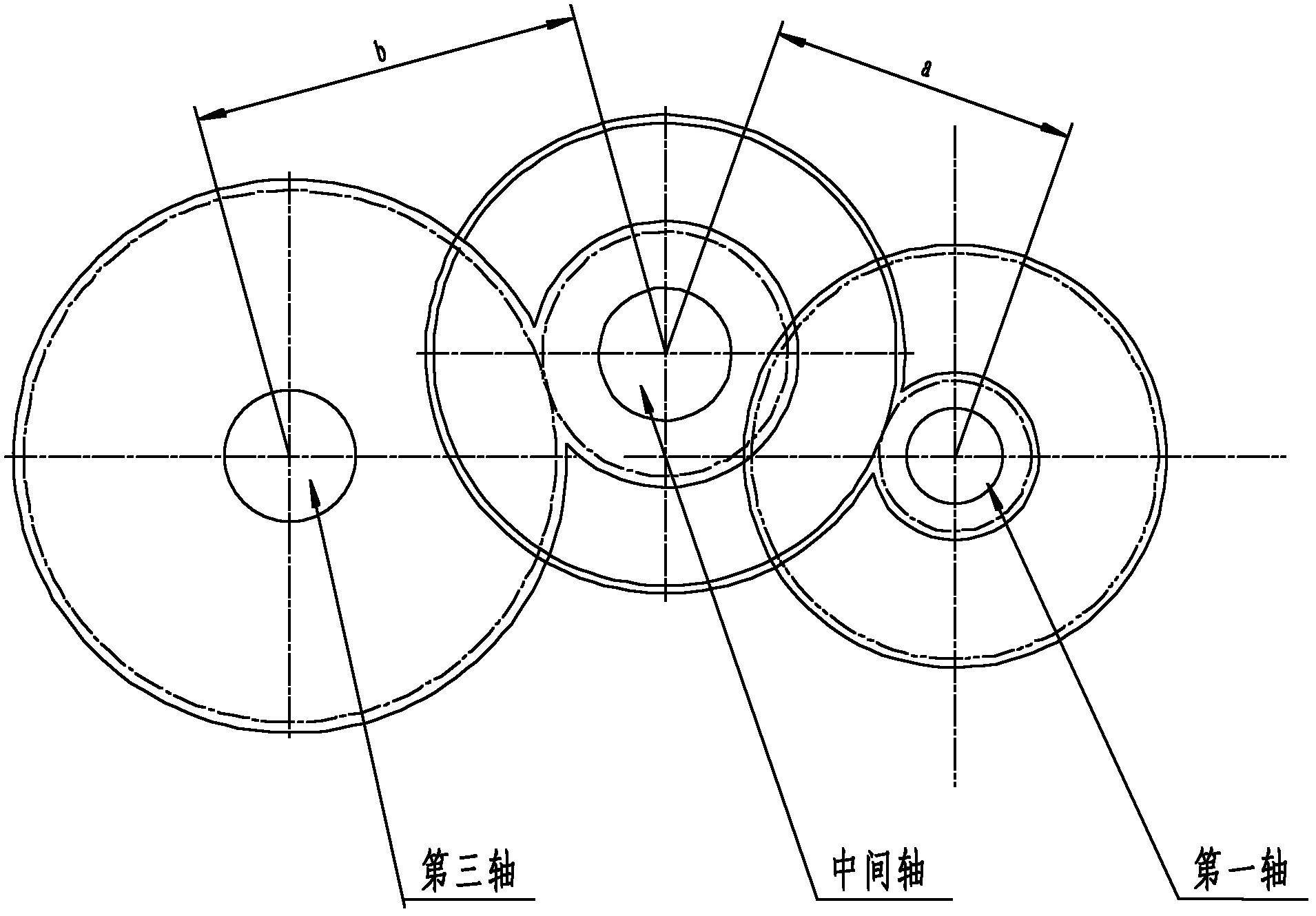

[0008] A gearbox for automatically adjusting the gear meshing gap provided by the present invention, the main components of the example mechanism include the first shaft, the third shaft, the intermediate shaft 2, the bearing 3, the eccentric sleeve 1, the torsion spring 4, the box body 5, etc. , when the gear wears and produces a gap, the torsion spring drives the eccentric sleeve to rotate counterclockwise ( figure 1 ), so that the position of the intermediate shaft moves down, reducing the wheelbase a between the intermediate shaft 2 and the first shaft and the wheelbase b between the intermediate shaft 2 and the third shaft, so as to achieve the purpose of reducing or even eliminating the meshing gap.

[0009] Among them, the bearing is a standard part, which can be selected according to the load; the manufacturing methods of the other eccentric sleeves, torsion springs, shafts, gears, boxes, etc. belong to the known technology, so they will not be explained here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com