An engine solenoid valve driving circuit and its control method

A technology of solenoid valve driving and engine controller, applied in the direction of engine control, electrical control, machine/engine, etc., can solve the problems of poor safety performance and stability, complicated circuit structure and driving mode, etc., to achieve stable performance and range of use. Extensive, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

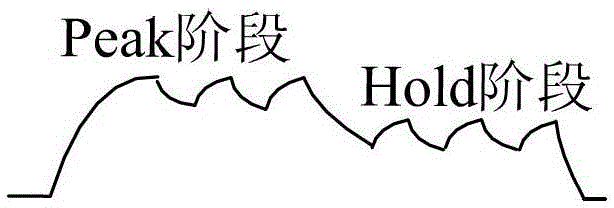

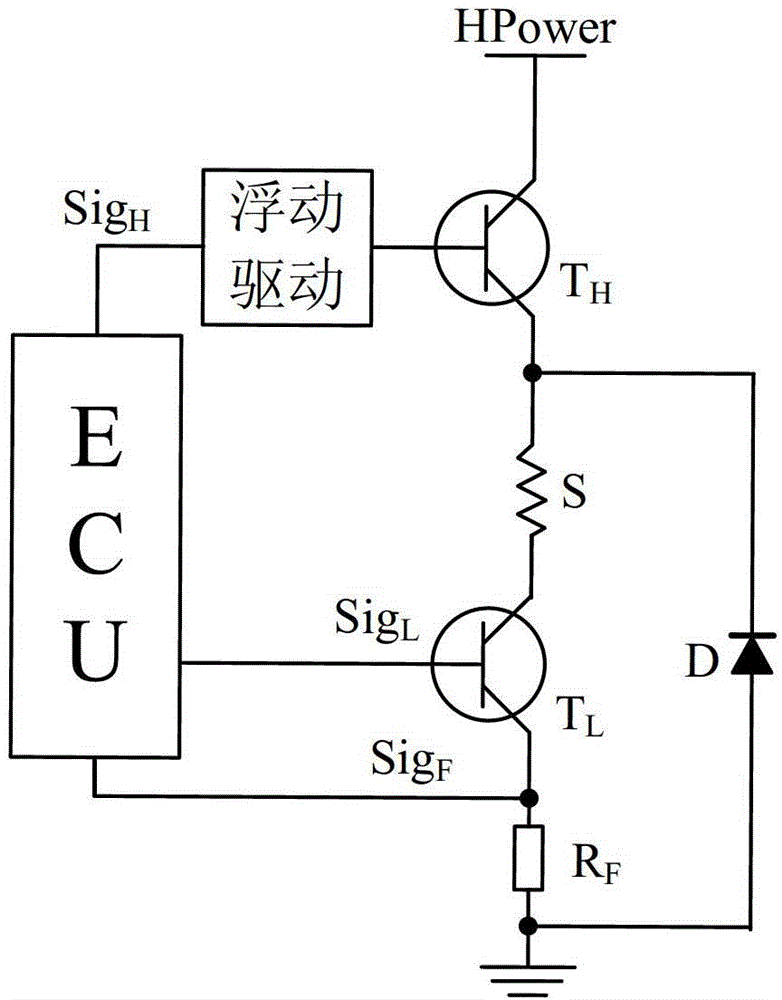

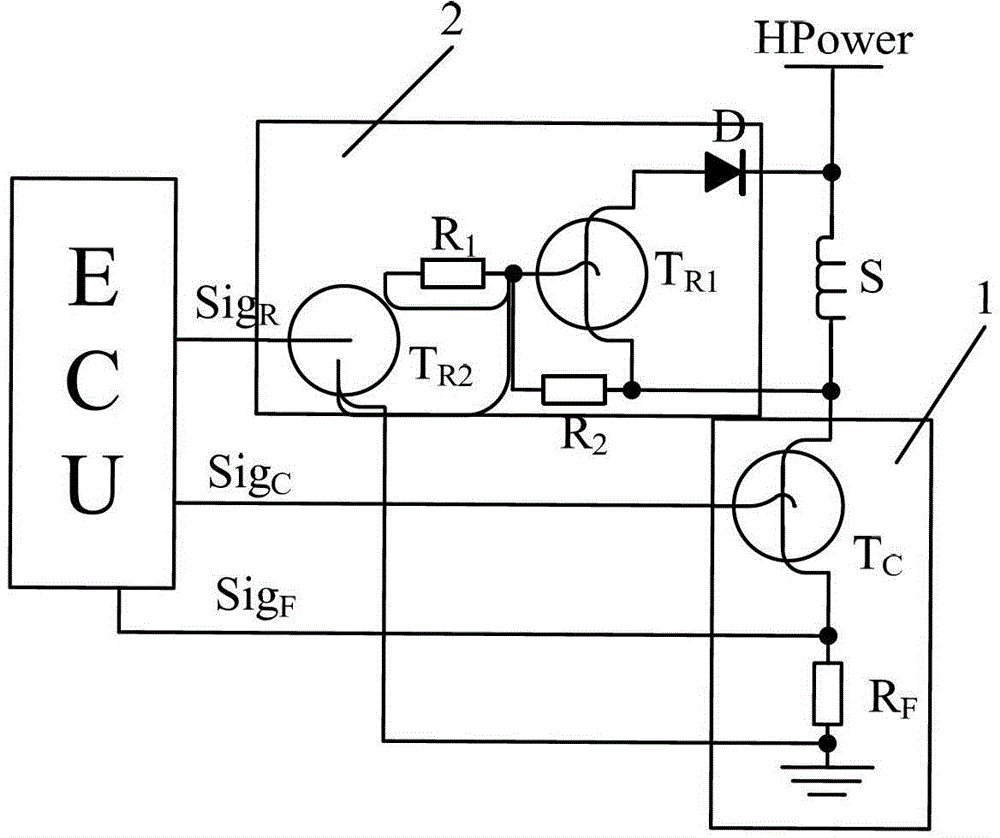

[0030] figure 1 , 2 The content shown is the drive circuit structure and its corresponding Peak & Hold drive current waveforms currently used by people. image 3 It is a structural schematic diagram of the engine solenoid valve driving circuit of the present invention, which is composed of a control triode circuit 1 and a freewheeling protection circuit 2 . Among them, S is the solenoid valve controlled by the drive circuit of the present invention, referred to as "controlled solenoid valve S"; ECU is the engine controller, and it has multiple input terminals and output terminals.

[0031] The control triode circuit 1 is composed of a sampling resistor RF and an N-type triode TC. When connected, the gate and source of the triode TC are directly connected to the ECU to receive the control signal SigC and the driving current sampling of the ECU respectively. Signal SigF. One end of the sampling resistor RF is grounded, and the other end is connected to the source of the triod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com