Tracking sewing equipment

A sewing equipment and equipment technology, which is applied to sewing equipment, program-controlled sewing machines, textiles and papermaking, etc., can solve the problem of the sleeves being unable to keep up, and achieve the effect of improving efficiency and ensuring sewing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

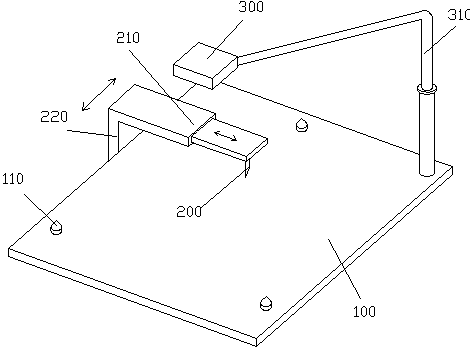

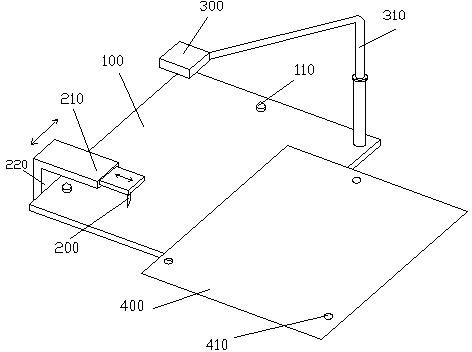

[0015] In this embodiment, the tracking suture equipment includes a suture platform 100, and the upper part of the suture platform 100 is provided with a numerical control two-axis positioning device, refer to figure 1 The said numerically controlled two-axis positioning device is provided with a stapler 200 facing the suturing platform 100 and a tracking device, said suturing platform 100 is provided with at least two positioning nails 110, and said positioning nails 110 are used for positioning a The transparent hard film 400 covered on the suturing platform 100 is provided with a positioning hole 410 corresponding to the positioning nail 110, and the transparent hard film 400 is passed through a tracing pen. The clothes to be stitched arranged on the stitching platform 100 are traced.

[0016] refer to figure 1 , figure 2 The numerical control two-axis posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com