A method of using a large load-bearing movable tool bracket

A tool table, heavy-duty technology, used in manufacturing tools, workbenches, metal processing, etc., can solve problems such as difficulty in improving production efficiency, slow inclination angle speed, and stable changes affecting assembly quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

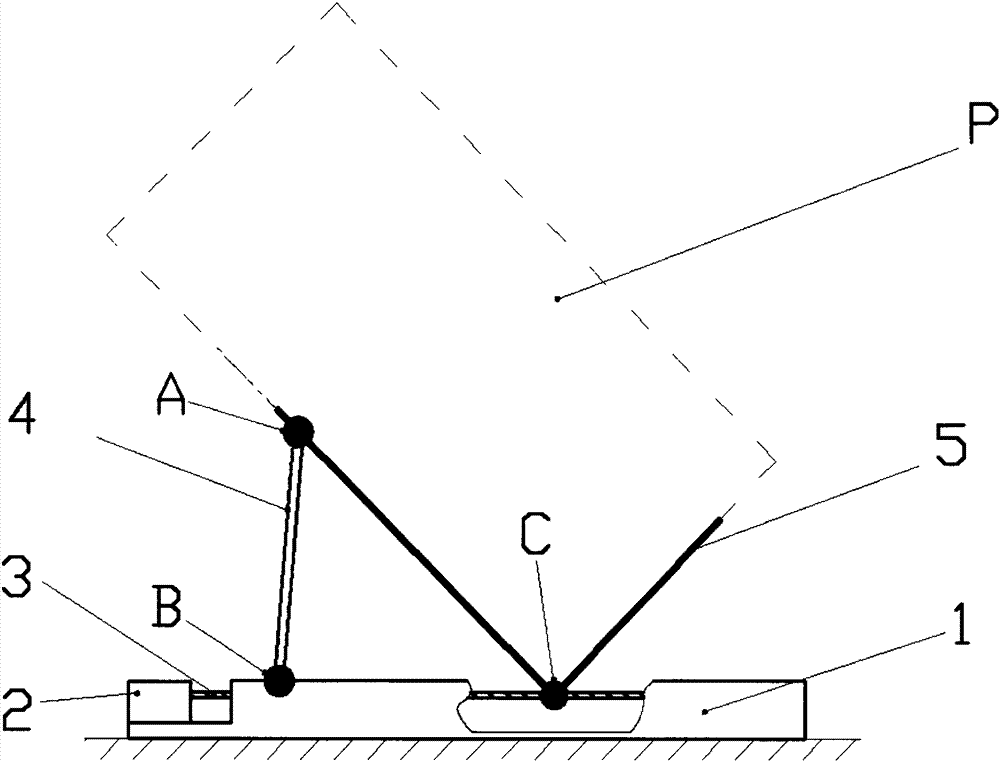

[0015] What is shown in the accompanying drawing is a kind of large-scale heavy-duty product P (such as: special switchboard, special large-scale tool microscope equipment, special large-scale three-coordinate tester, etc.) placed mainly vertically, and can be placed in multiple One or more tool tables placed at different inclination angles (generally no more than 45 degrees based on the vertical) to implement fastening and assembly services for complex large parts or / and small components; generally, such large-sized heavy-duty The product P cannot do without the assistance of a crane during its displacement and / or placement.

[0016] The main details of the present invention in an embodiment shown in the figure are:

[0017] The load-bearing right-angle pallet 5 is composed of a long supporting wall with a height of 2M and a width of 1.2M and a 1.2M square chassis arranged at right angles to the long supporting wall. Holes are formed in the sheet metal frame.

[0018] The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com