Lower thread supply device for sewing machine

一种供应装置、缝纫机的技术,应用在缝纫机中梭心绕线、缝纫机元件、缝纫机用套圈机构等方向,能够解决钩梭体20振动或抖动等问题,达到增加一次装载量、增加大小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the drawings.

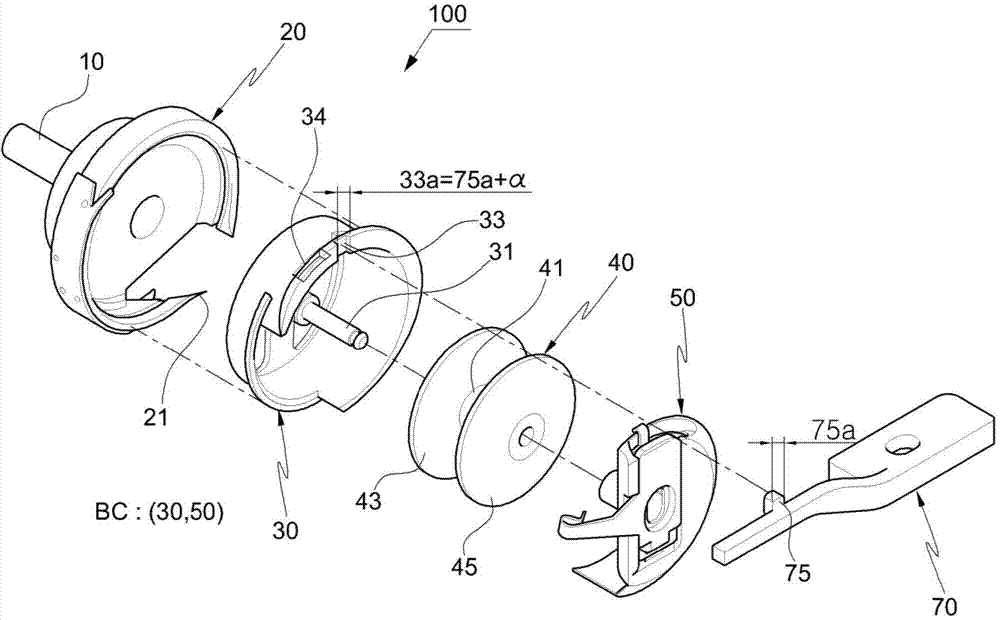

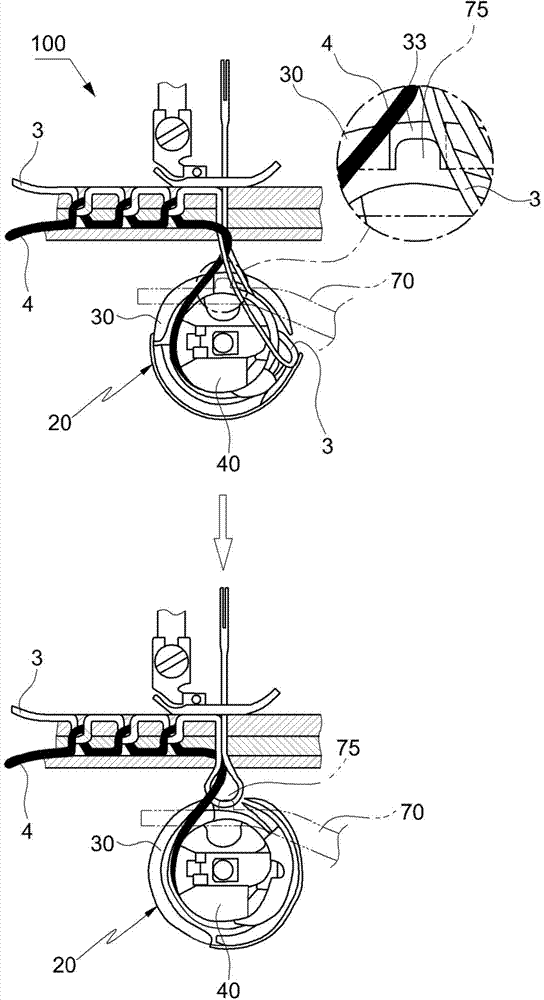

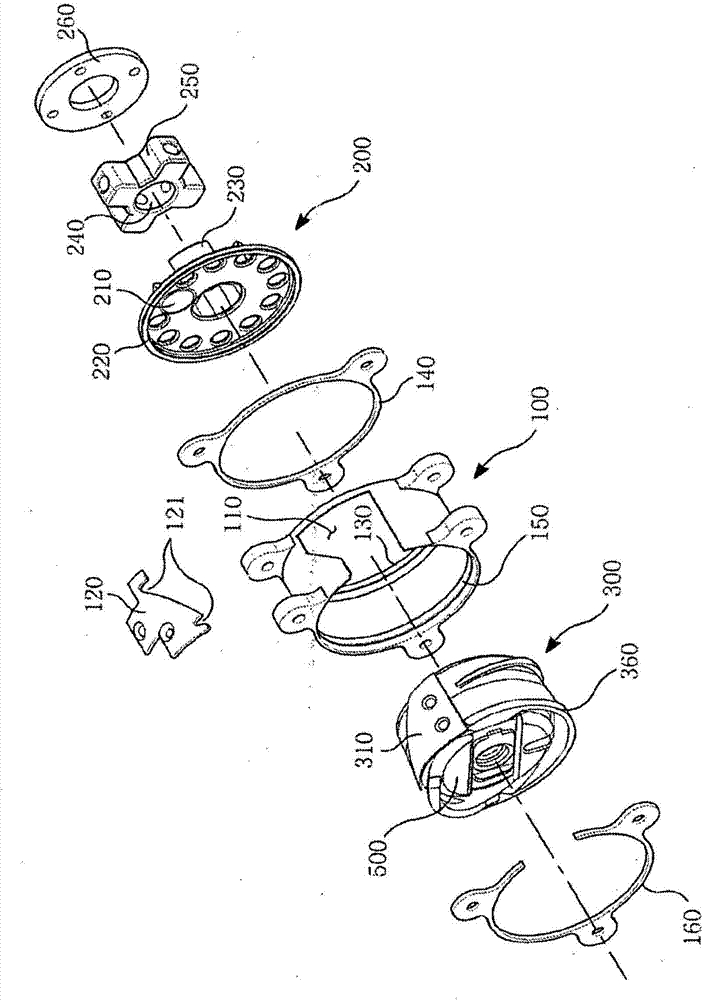

[0067] Figure 3 to Figure 5 Shown is an exploded perspective view of the present invention, when combined with the components shown in the exploded perspective view can be completed as Image 6 Lower thread supply unit shown.

[0068] The housing 100 is fixed at the lower part of the main body of the sewing machine or in place according to the characteristics of the sewing machine, the housing 100 being formed in a cylindrical pipe shape with its front and rear sides opened along the central axis.

[0069] The casing 100 can be fixed to the main body of the sewing machine by various usual brackets, fixing bolts, pins, etc., and the description thereof will be omitted here. The housing 100 is fixedly installed on the main body of the sewing machine so that even if the power shaft of the sewing machine is rotated, the housing will not rotate and rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com