Device and method for completely removing at least one part of the breast cartilage from a poultry carcass that is free of breast meat

A complete separation and part of the technology, used in poultry segmentation, poultry deboning, poultry processing and other directions, can solve problems such as residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

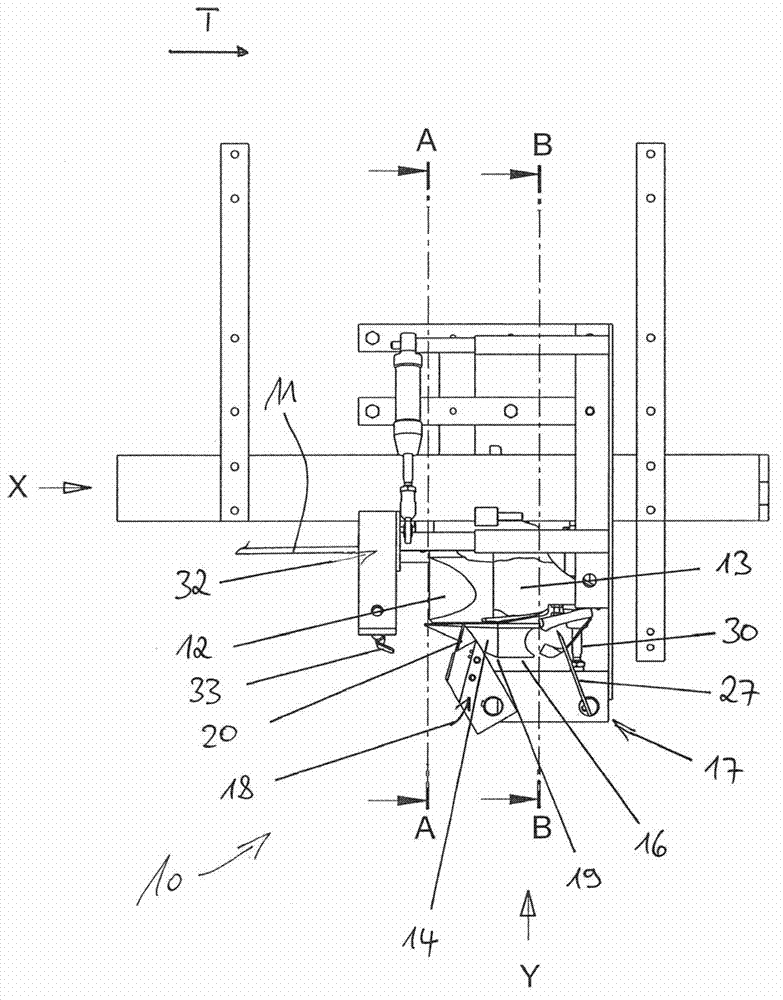

[0028] The apparatus shown in the above figures is used to automatically separate breast cartilage or a portion of breast cartilage from poultry carcasses. The unit can be used as a stand-alone machine or as part of a production line.

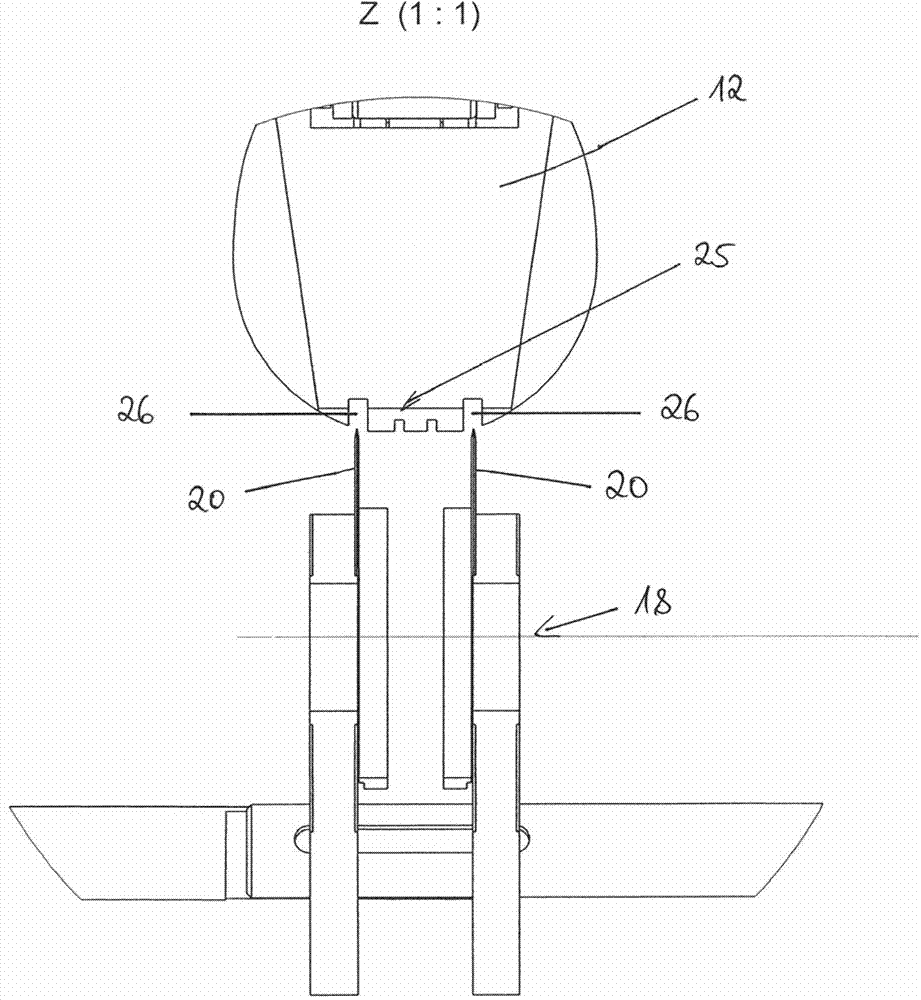

[0029] figure 1 A side view of the device 10 is shown. The device 10 essentially comprises a conveyor belt 11 having at least one support body 12 for receiving and fixing poultry carcasses 13 . Generally speaking, the conveyor belt 11 is a rotary conveyor chain with a plurality of supports 12 . However, other common forms of conveyor belt 11 may also be used. By means of this conveyor belt 11 , the poultry carcasses 13 fastened to the support body 12 are conveyed in the conveying direction (arrow T), that is to say along the cutting means 17 which are also part of the device 10 according to the invention. According to the invention, the cutting mechanism 17 comprises a double blade 18 and a separating member 27 arranged downstream of the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com