Whole-process optimizing method of multi-stage batch production process

A production process and optimization method technology, applied in the direction of instruments, adaptive control, control/regulation system, etc., can solve problems such as ignoring the continuity of product quality, incomplete SIC theory, and cumbersome operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

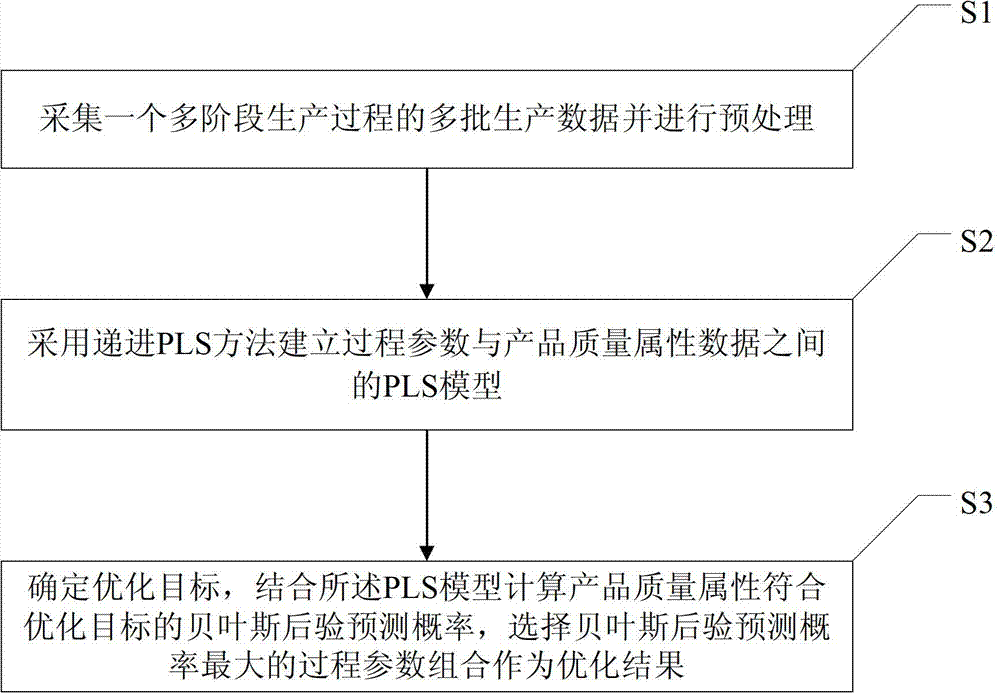

Method used

Image

Examples

Embodiment Construction

[0064] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings

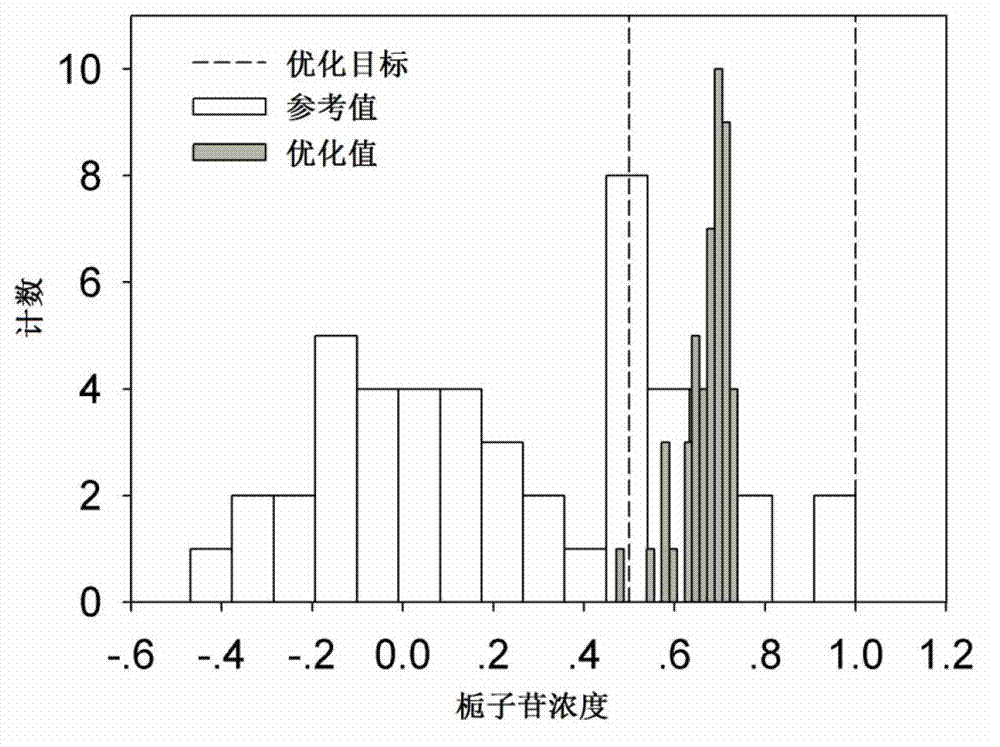

[0065] A preparation process of the traditional Chinese medicine gardenia extract, which mainly includes six process units of extraction, concentration, alcohol precipitation, alcohol collection, water precipitation and refining, which is a typical multi-stage batch production process. Through six-stage production operations, the active ingredient geniposide is transferred from the gardenia medicinal material to the gardenia extract, and the impurity components are continuously removed. The content of geniposide in the gardenia medicinal materials and gardenia extract was determined by HPLC. The goal of the process is to avoid the loss of geniposide in the multi-stage production process as far as possible, and at the same time keep the content of geniposide in the extract of Gardenia jasminoides stable within a certain range.

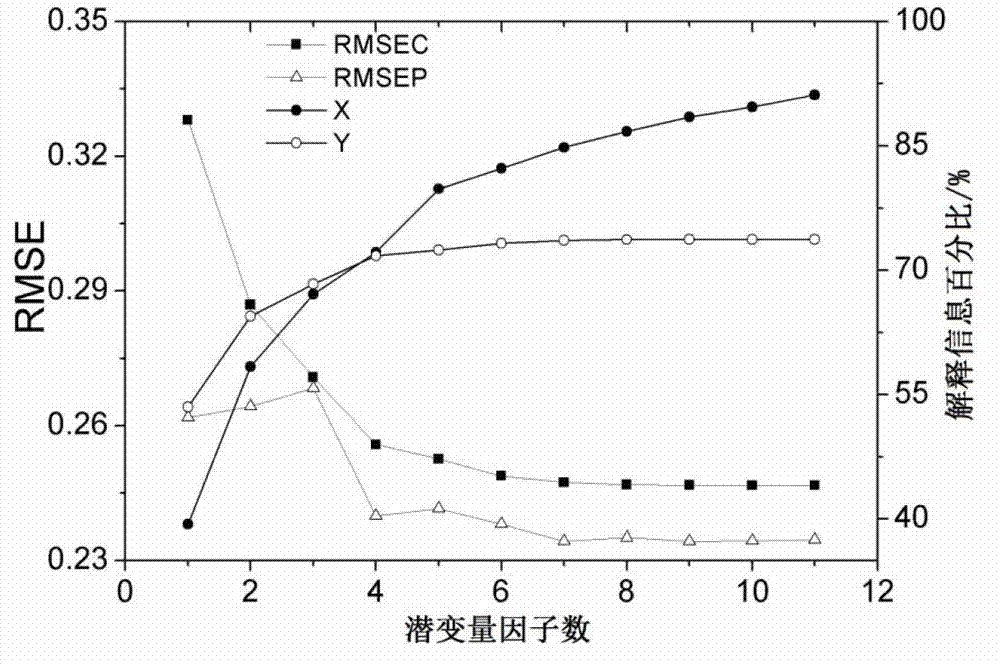

[0066] Taking t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com