Fixed device and furnace body temperature measuring optical cable wiring method

A technology of fixing devices and wiring methods, which is applied in the direction of measuring devices, thermometers, measuring heat, etc., to achieve the effects of prolonging service life, simple construction, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

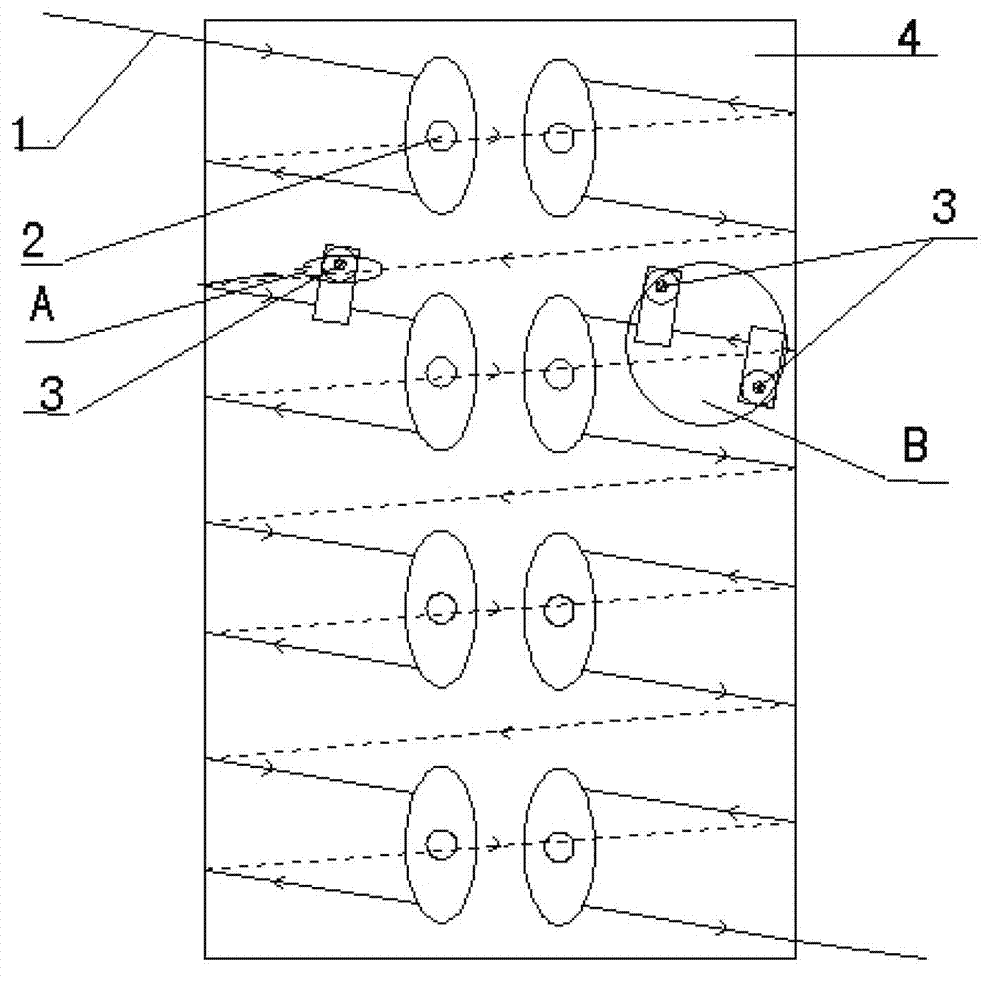

[0024] Such as figure 1 As shown, the present embodiment provides a method for wiring a furnace body temperature measurement optical cable, which is used for wiring on a furnace body with a connecting pipe 5, and only performs wiring and temperature measurement on the furnace body 4, and in the furnace body 4 Two rows of first fixing devices 2 and first nuts 21 arranged perpendicular to the ground plane are welded on the surface, and the distance between adjacent first fixing devices 2 is 500mm. The arc-shaped spring pieces 22 corresponding to the two rows of first fixing devices 2 are respectively relatively placed. The optical cable 1 is bypassed on the arc spring piece 22 of the first first fixing device 2 in the first row at the starting point of the wiring, reversely wound to the first first fixing device 2 in the second row, and from the second row to the first fixing device 2. The arc-shaped spring piece 22 of the first first fixing device 2 in the first row is bypasse...

Embodiment 2

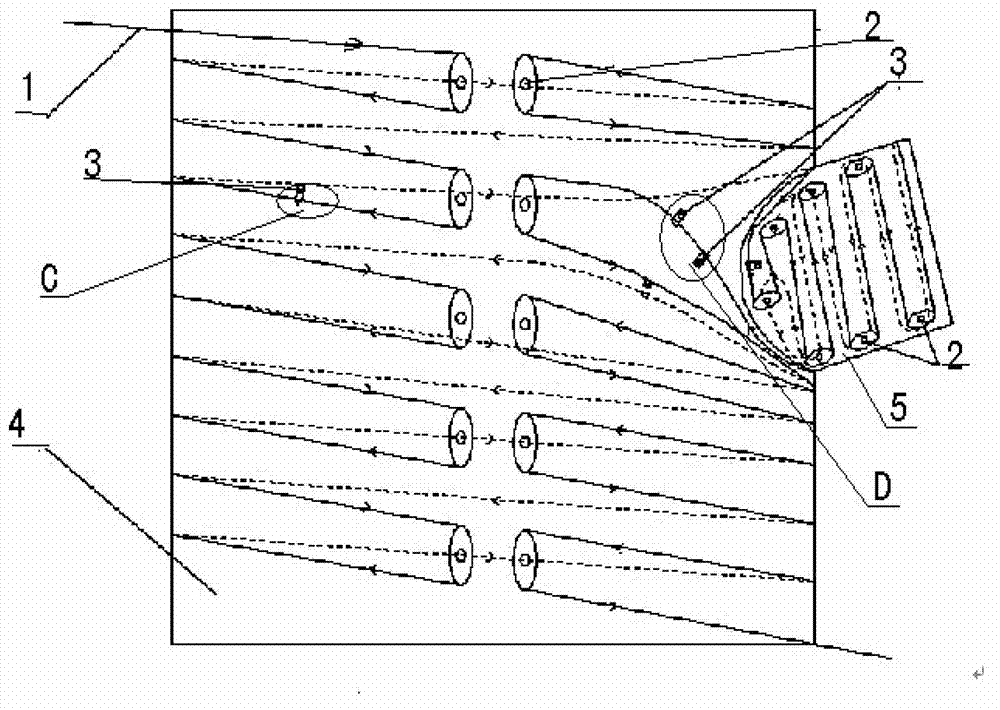

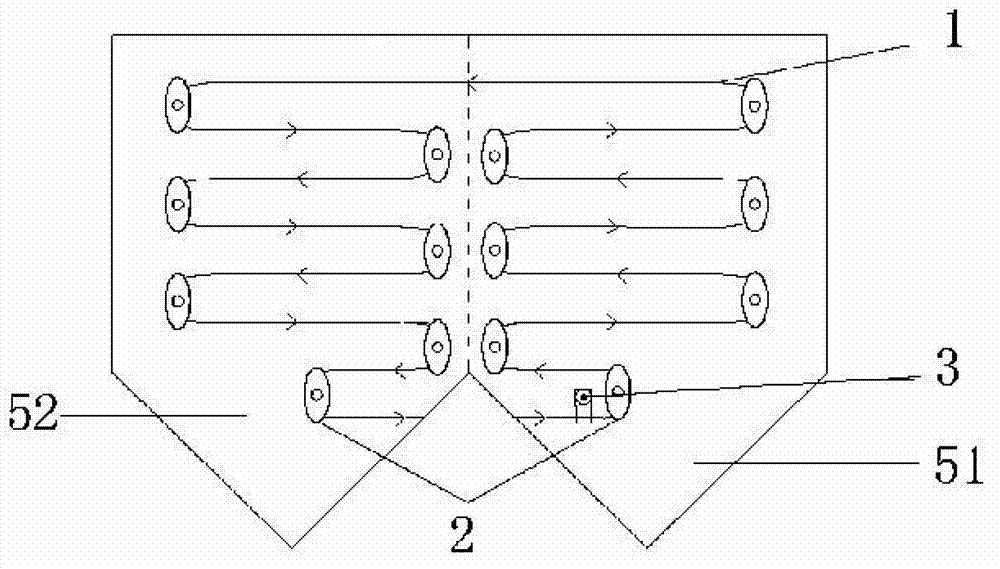

[0026] Such as figure 2 As shown, this embodiment provides another method for wiring the furnace body temperature measuring optical cable. Compared with Embodiment 1, this embodiment, in addition to the temperature measurement of the furnace body 4 wiring as in Embodiment 1, also measures the temperature of the furnace body 4. The connecting pipe 5 of the body is used for wiring temperature measurement. Such as image 3 As shown, the connecting pipe 5 of the furnace body is divided into a first part 51 and a second part 52 from the axial direction. The surface of the second part 52 is welded with two rows of first fixing devices 2 respectively, and the first nut 21 is welded at each turn of the serpentine cable wiring; At the same time, the first part 51 on the furnace body connecting pipe 5 is bypassed on each of the first fixing device arc-shaped spring pieces 22 in turn, so that the optical cable is wound from the furnace body connecting pipe 5 head to the furnace body c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com