Baffle-type one-way overspeed cut-off valve

An overspeed closing and baffle-type technology, which is applied in the direction of valve details, valve devices, and functional valve types, can solve problems such as misoperation, leaking gaskets, and large frictional damping, and achieves small flow rate setting errors and tight seals. The effect of improving the effect and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

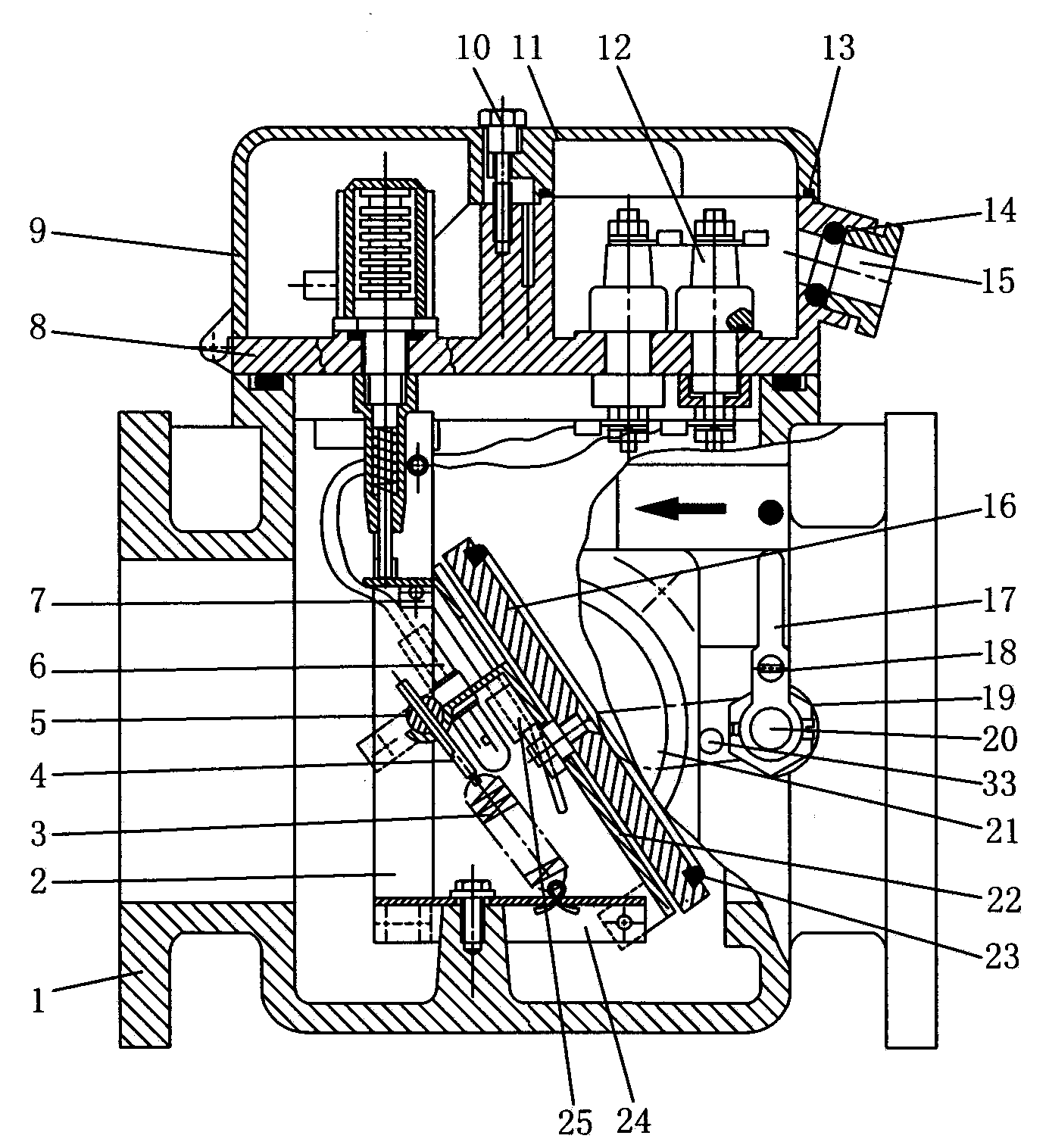

[0029] Depend on Figure 1 ~ Figure 2 As shown, the main structure of the present invention is as follows: it comprises valve body 1, bonnet 8, valve plate 16, glass window 32 and reset handle 17, is provided with an angle frame in valve body 1, and this angle frame is formed by stand frame 2 and base plate 24, the stand 2 is hinged with a test fork 7 inclined to the bottom plate, and the stand 2 is also provided with four reed contacts 6 parallel to the test fork 7, and the stand on the upper side of the test fork 7 The frame 2 is also provided with a reset connecting rod 28, and a reset spring 26 is connected between the reset connecting rod 28 and the upper edge of the test shift fork 7; Magnets 25 are arranged on the lower side of the active plate 22 corresponding to the positions of the reed contacts 6, and an extension spring screw mechanism is arranged between the active plate 22 and the bottom plate 24. The extension spring screw mechanism includes an extension spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com