Drum-type drying device of cloth

A drying device, a drum-type technology, which is applied to washing devices, household dryers, ironing machines, etc., can solve the problems of low production efficiency and inability to continuously dry fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

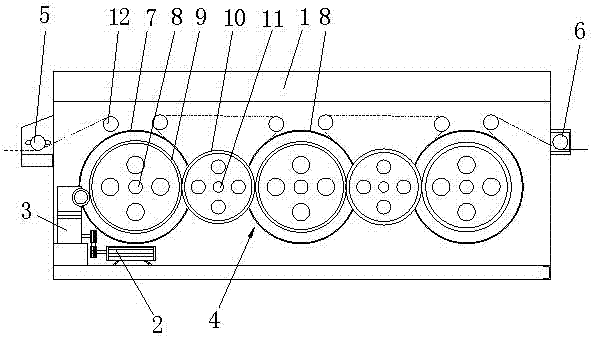

[0017] Such as figure 1 As shown, the cloth drum drying device according to the embodiment of the present invention includes a fuselage 1, a power device 2, a transmission device 3 and a drum device 4. The power device 2 drives the transmission device 3 to rotate, and the body 1 One end is provided with feed guide roller 5, and the other end is provided with discharge guide roller 6; The roller device 4 includes a roller body 7 and a rolling shaft 8, and the roller body 7 is fixedly connected with the rolling shaft 8; The number is three, and the number of rolling shafts 8 is three. One side of each rolling shaft 7 is provided with a transmission gear 9, and the transmission device 3 drives the transmission gear 9 close to the feed guide roller 5 to rotate; An intermediate gear 10 is meshed between the large transmission gears 9, and the intermediate gear 10 is arranged on the transmission shaft 11; two transmission guide rollers 12 whose spacing is smaller than the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com