Disposable bag and a disposable bag mount bracket for an upright vacuum cleaner

A technology of vacuum cleaners and vacuum bags, applied in cleaning equipment, applications, suction filters, etc., can solve the problems of increasing vacuum cleaners, increasing the failure of internal parts, increasing manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

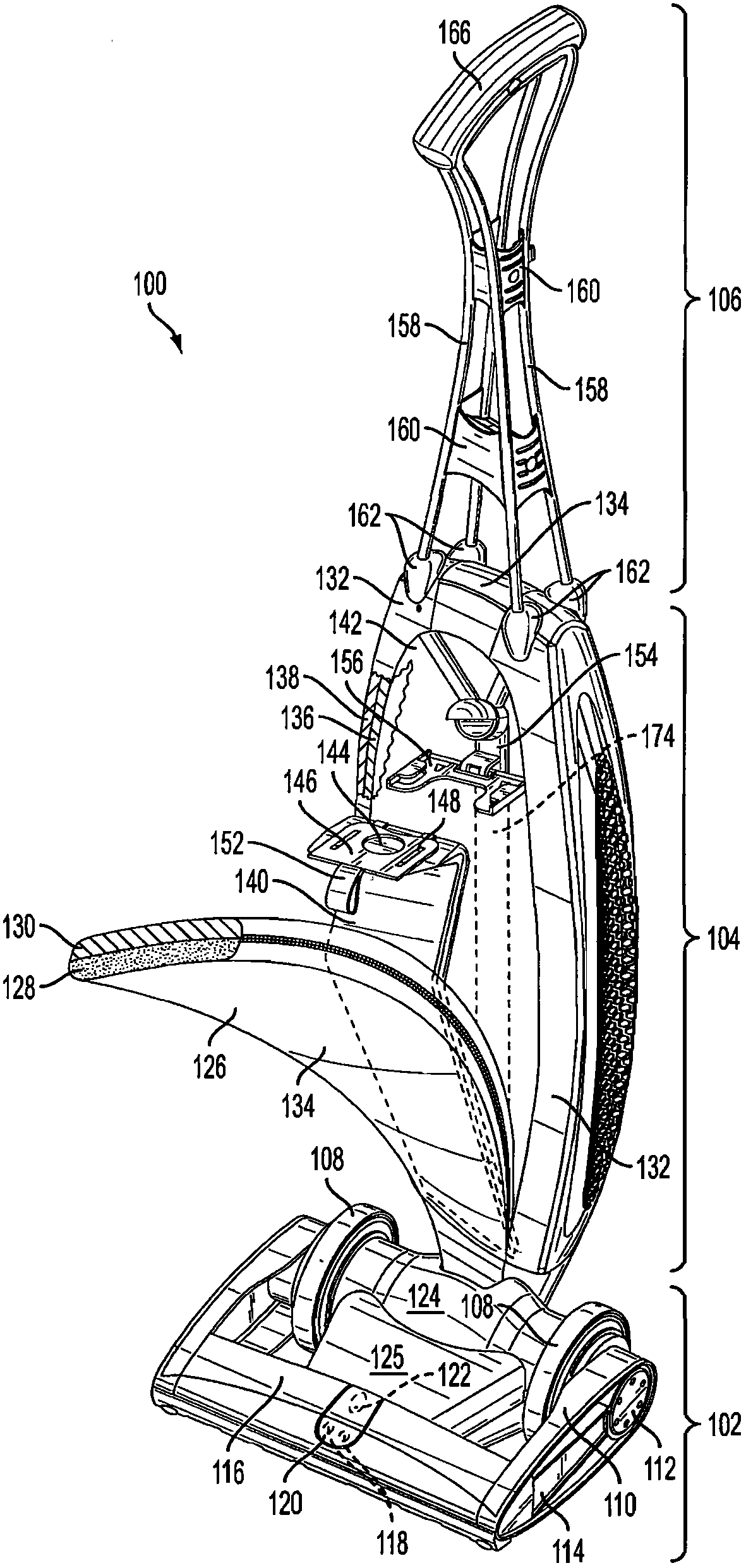

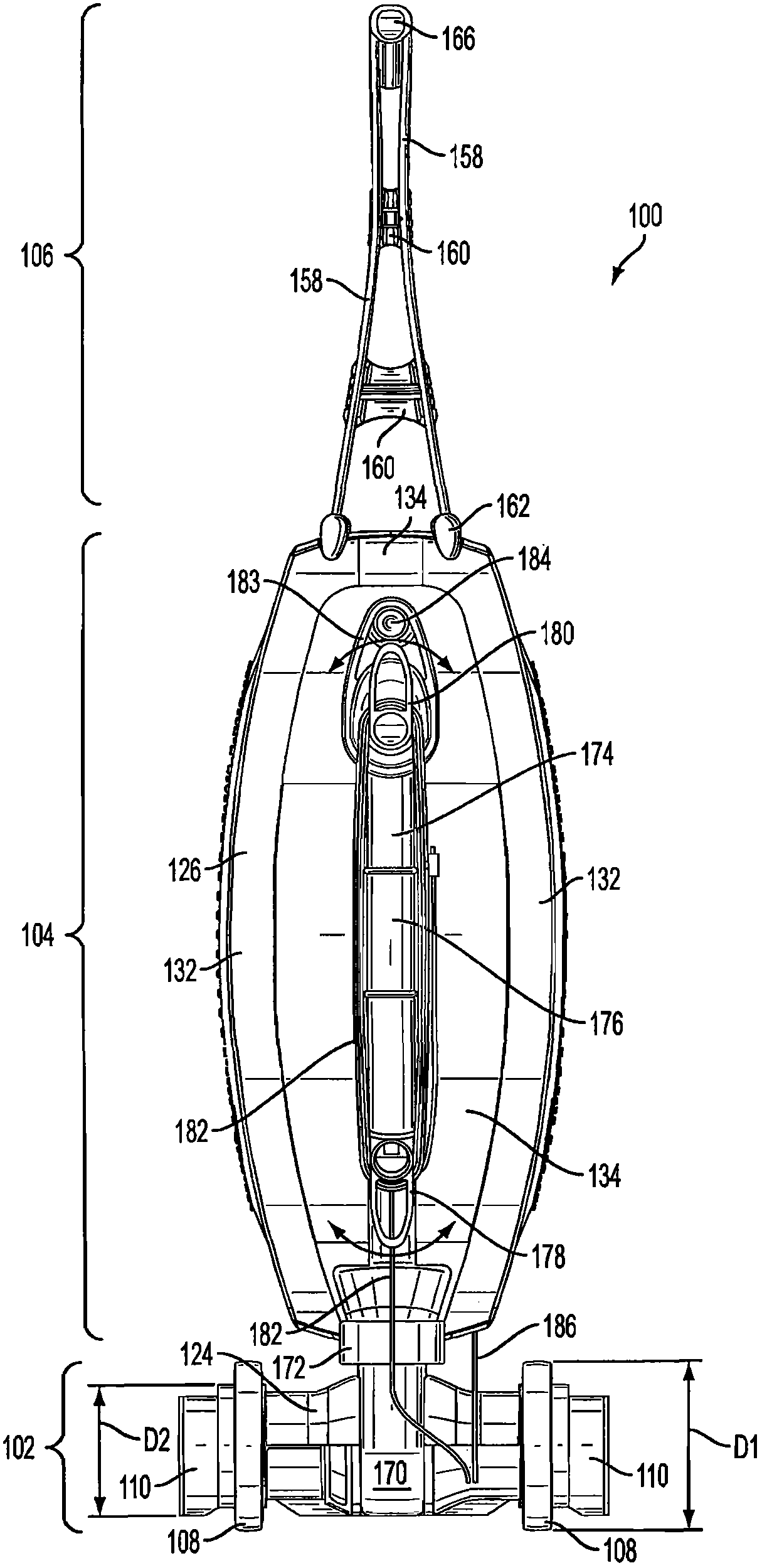

[0021] The present invention provides an upright vacuum cleaner including a vacuum cleaner base that provides improved cleaning characteristics and longevity. The construction of the vacuum cleaner may include a handle, a body, a base and wheel mounts capable of housing a motor. The placement of the motors within the wheel mounts reduces the weight of the vacuum cleaner, thereby reducing manufacturing costs. The increased wheel diameter makes handling of the vacuum cleaner extremely easy, whereby the unit is simple and lightweight for consumer use.

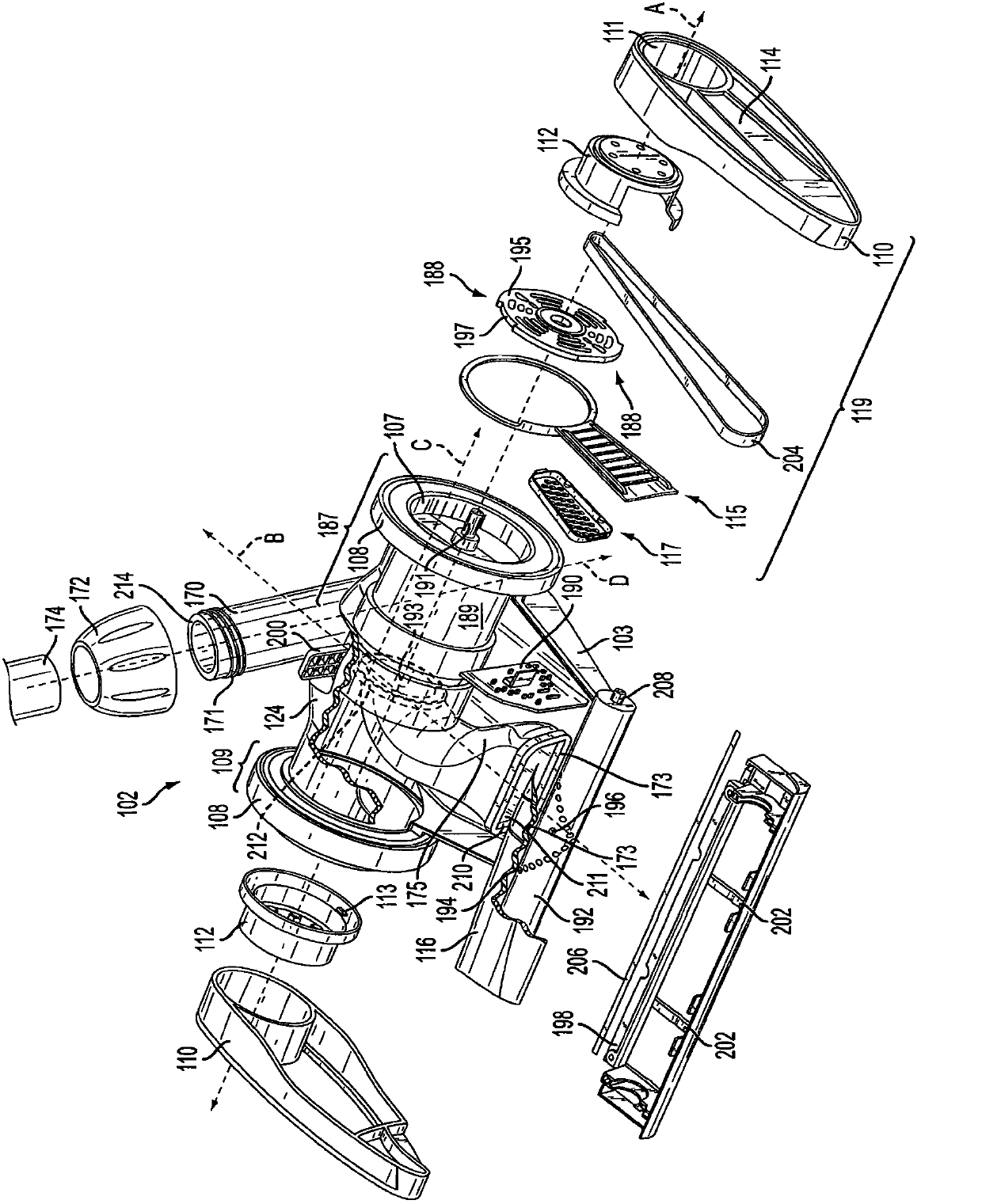

[0022] figure 1 and 2 An exemplary embodiment of an upright vacuum cleaner 100 is shown. Vacuum cleaner base 102 is connectable to dust collection assembly 104 and handle portion 106 . The vacuum cleaner base 102 may also include wheels 108, a beater bar housing 116 and a window / light housing cover 120 surrounding the light emitting diodes 118 and Hall effect sensors 122 for improved cleaning capabilities of the upright vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com