An Online Test Method for Characteristic Parameters of Bearing-Rotor System

A characteristic parameter, on-line testing technology, applied in mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as difficult on-line measurement of bearing-rotor systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is described in further detail below in conjunction with accompanying drawing:

[0058] Taking the small-scale multifunctional rotor-bearing test bench in the key laboratory of modern design and rotor bearing system of the Ministry of Education of Xi'an Jiaotong University as an example, the implementation process of the present invention is specifically introduced:

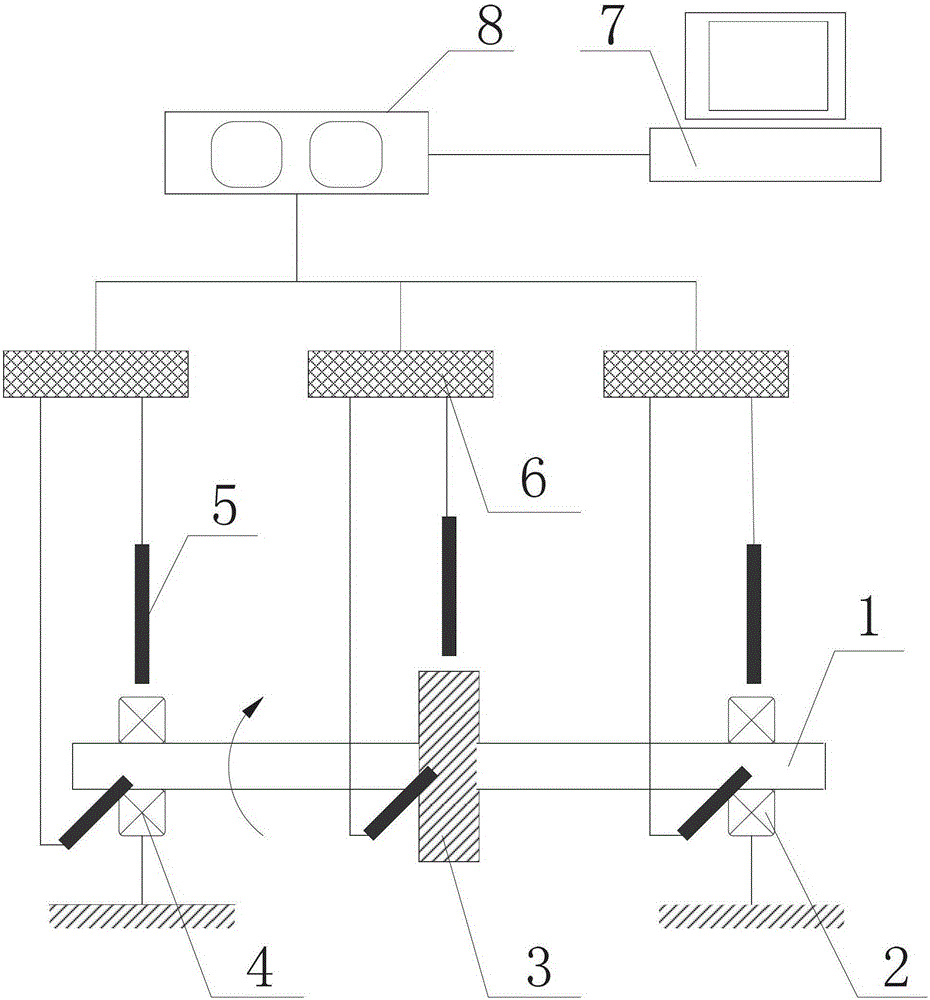

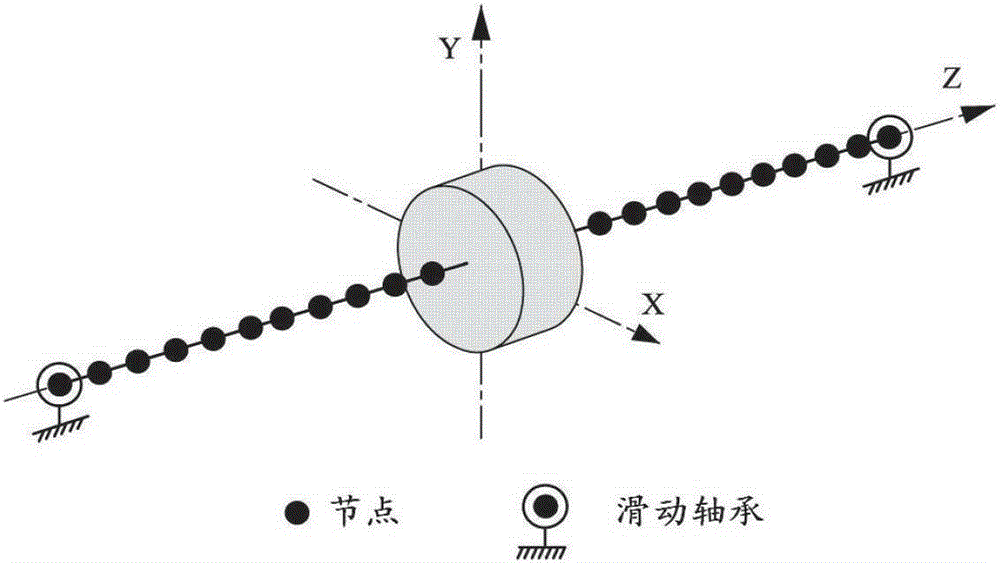

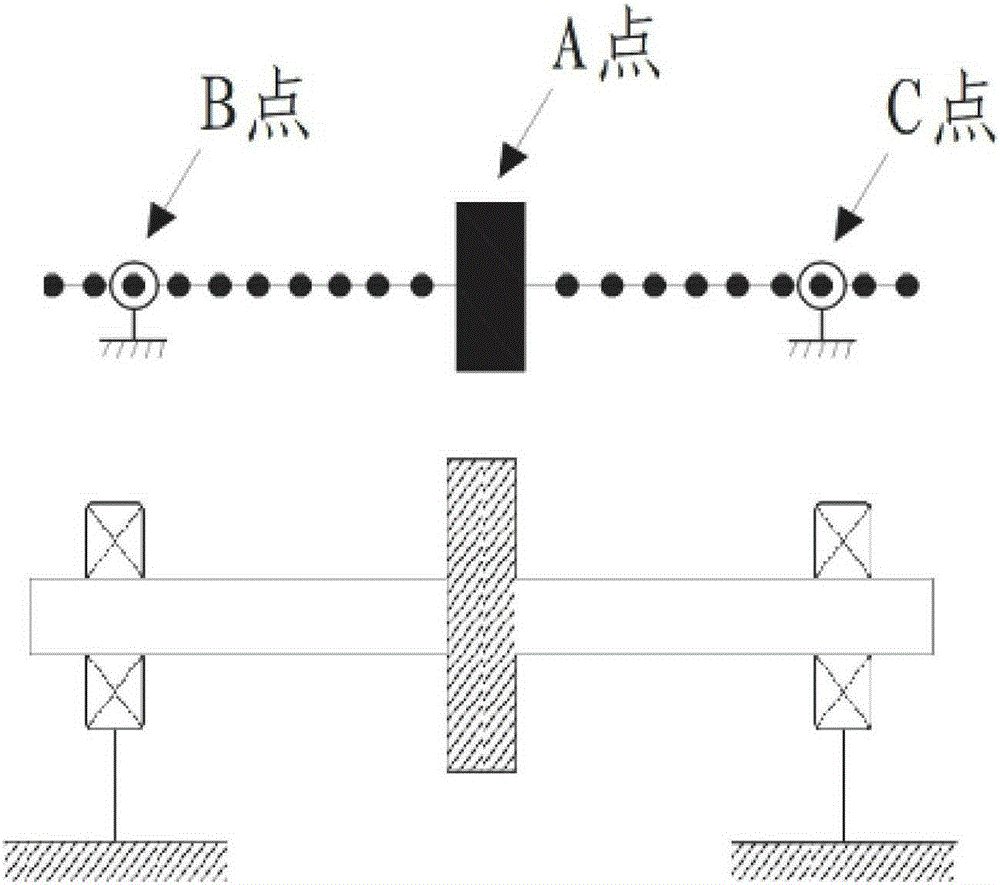

[0059] Step 1, see figure 1 , on the bearing-rotor system supported by the sliding bearing, the eddy current displacement sensor 5 is installed at the first sliding bearing 2, the second sliding bearing 4 and the mass disk 3 at 90° to measure the horizontal and vertical directions. Vibration signal, point C signal at the first sliding bearing 2, point B signal at the second sliding bearing 4, and point A signal at the mass disk 3; , the signal acquisition instrument 8 is connected with the computer 7, and the mode of adding an eccentric mass on the mass disk 3 is used for excitation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com