High-position inclined E-type ventilation system of coal face

A technology for coal mining face and ventilation system, which is applied in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc. problems, to achieve the effect of reducing road maintenance problems, saving manpower and material resources, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

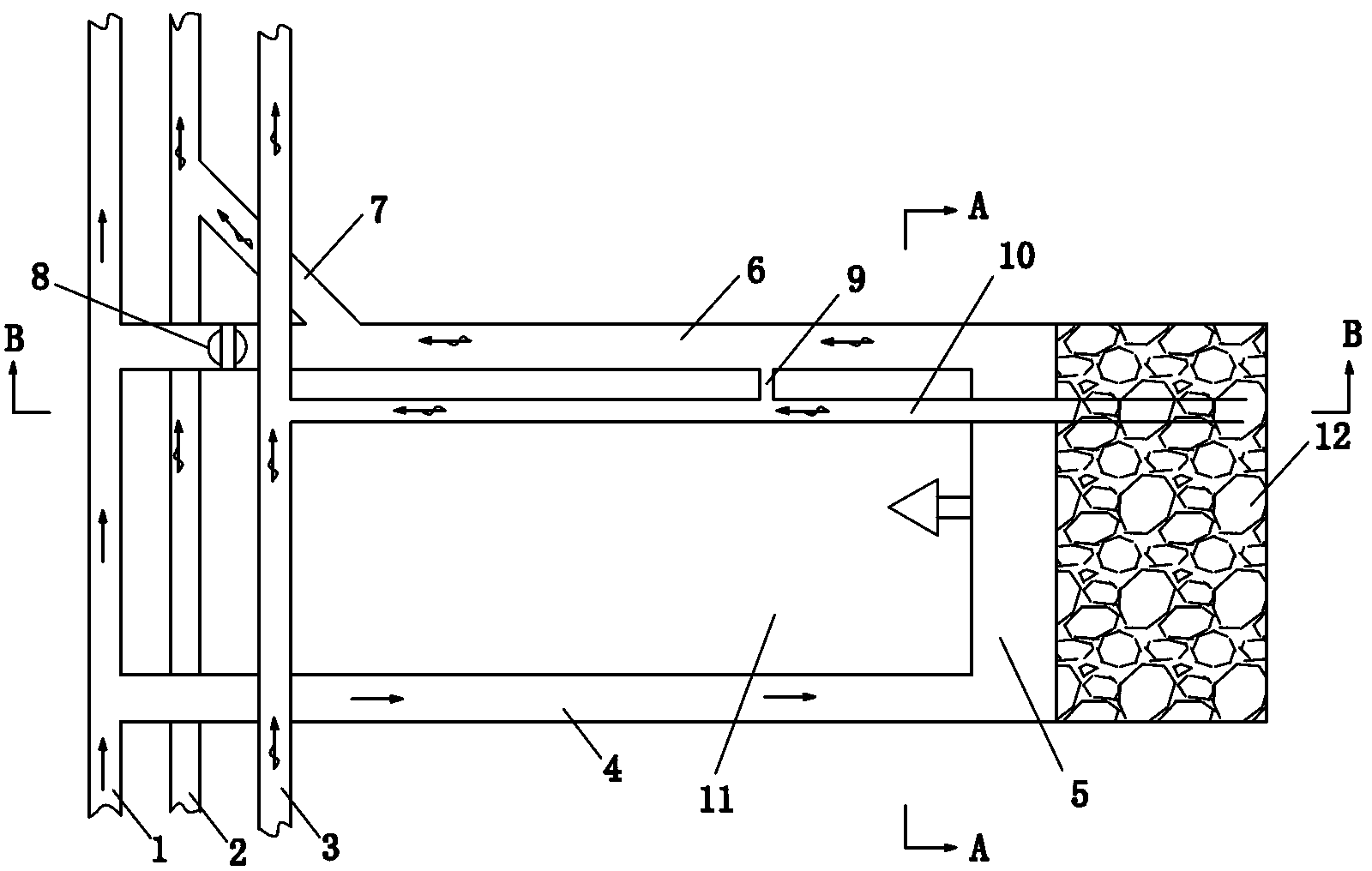

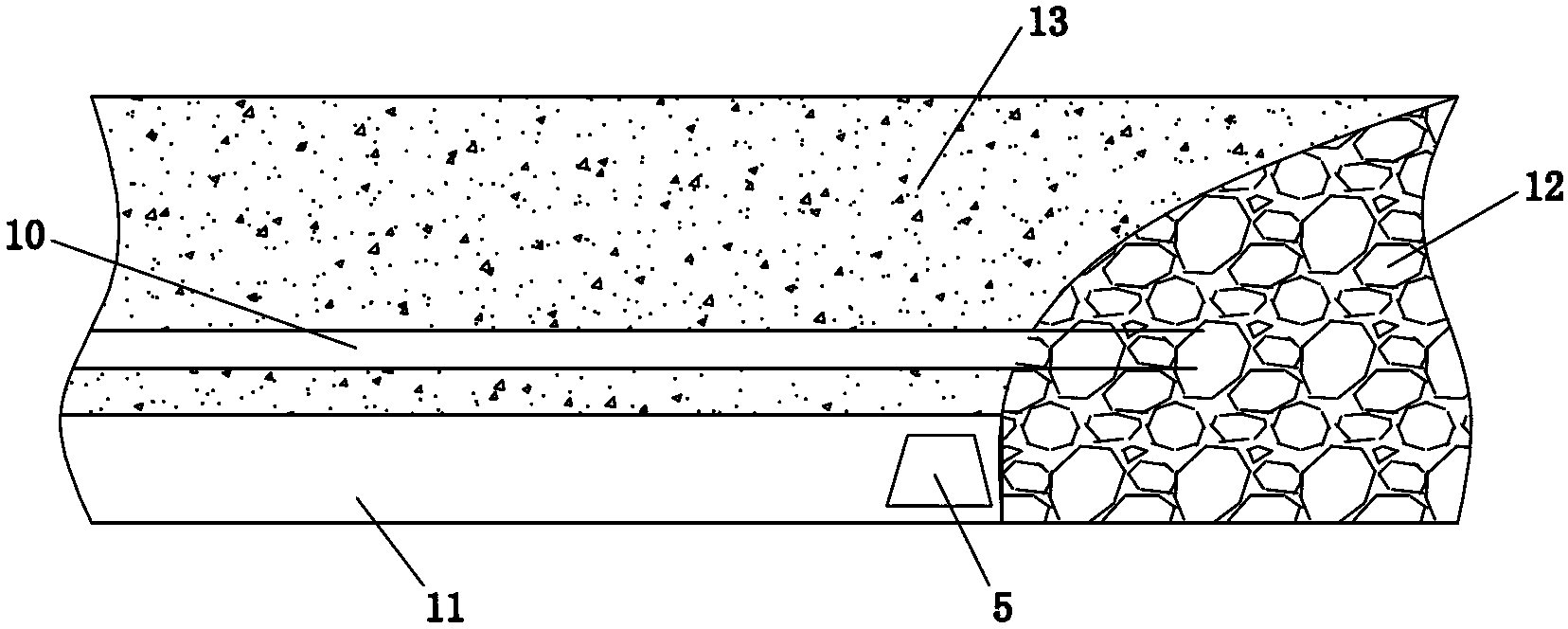

[0015] As shown in the figure: a high-level partial E-type ventilation system in a coal mining face, an air inlet lane 4 and a return air lane 6 are arranged in the coal mining area 11, and the return air lane and the air inlet lane are close to the return air lane. There is a high-level gas discharge lane 10 in the upper rock layer 12 of the coal seam of the wind lane, forming a high-level partial "E" ventilation system of "one inlet and two loops". pressure, restrain the gas in the goaf 12 from gushing to the upper corner of the mining face and the return airway, and guide the gas in the goaf to move to the special gas roadway 3.

[0016] One side of the air inlet alley and the air return alley is respectively equipped with an air inlet uphill 1, a return air uphill 2 and a special gas alley 3; between the return air uphill and the return air alley there is a return air level alley 7, and the return air There is also damper 8 on the wind alley.

[0017] A connecting lane 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com